Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

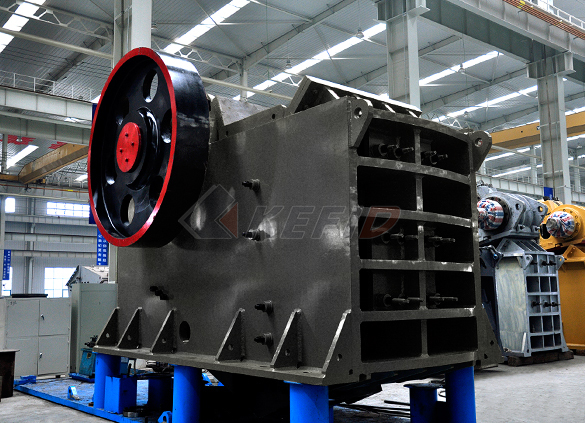

JC series jaw crusher

-

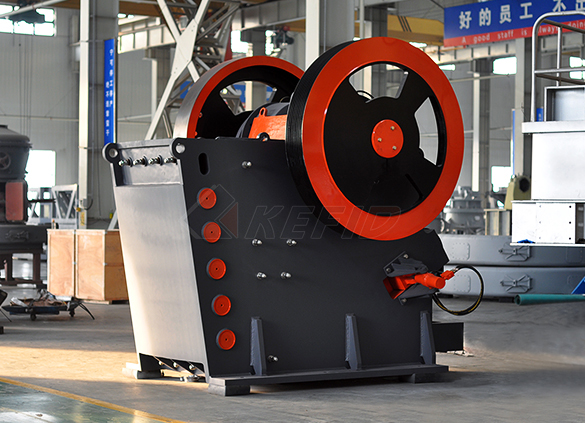

Jaw crusher

-

HJ series jaw crusher

-

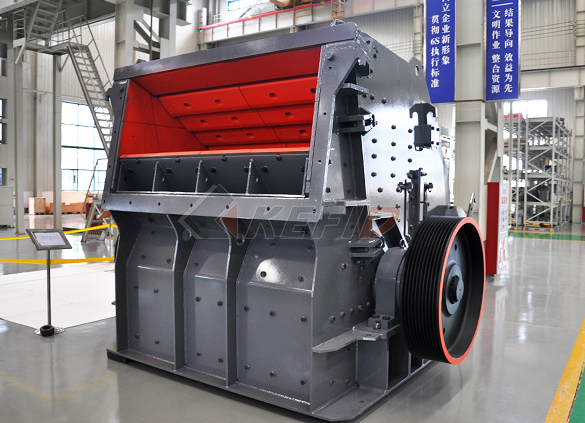

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

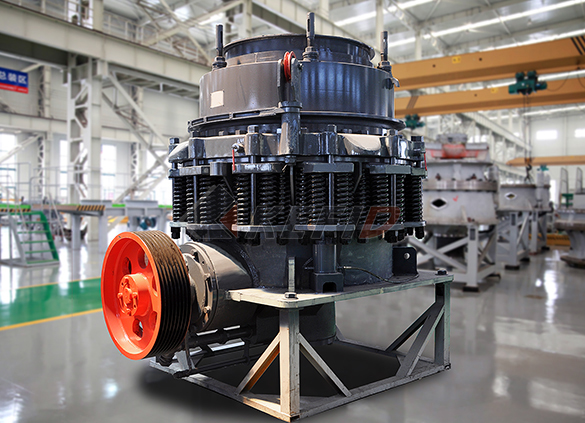

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

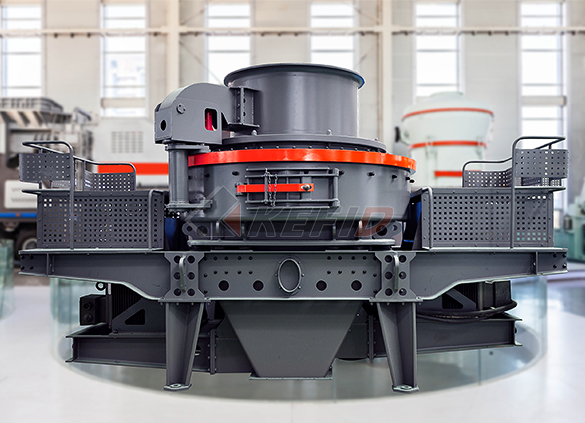

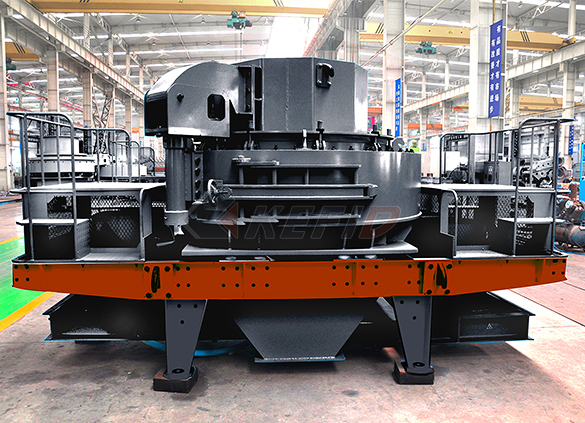

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

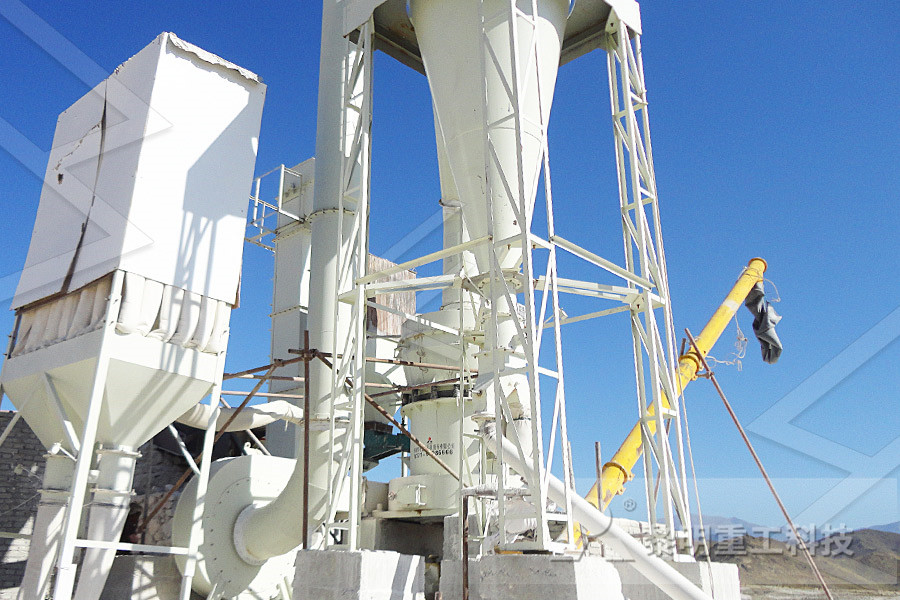

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

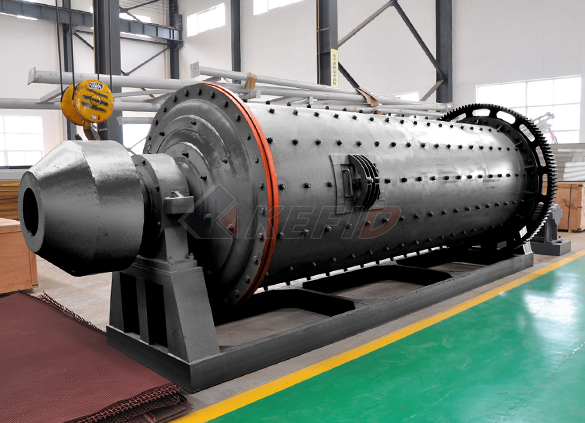

Ball mill

-

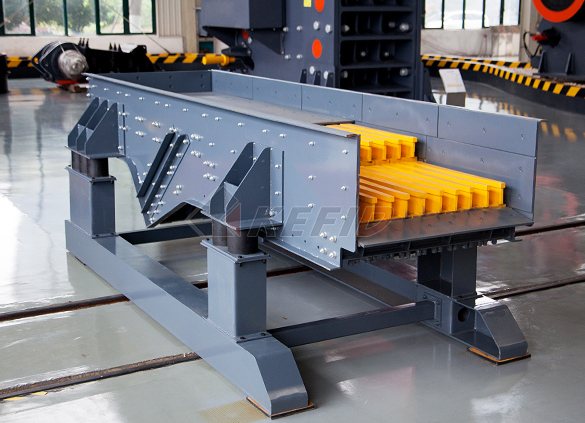

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

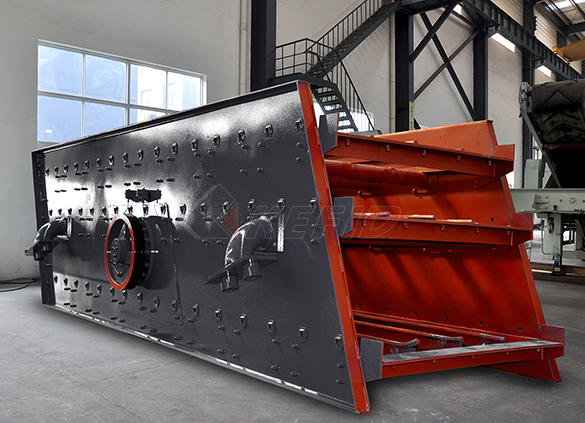

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

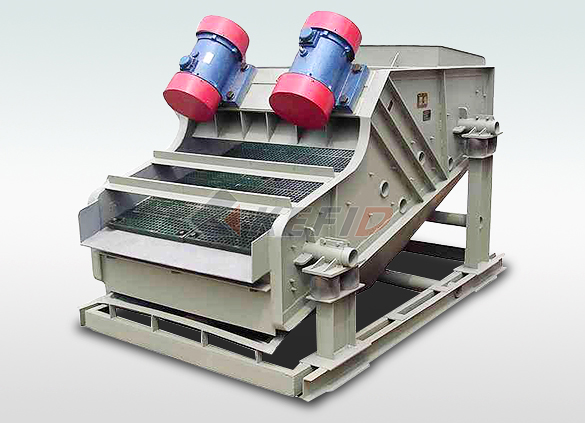

High frequency screen

Crushing in Mineral Processing

In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing Importance of Crusher Industry in Chemical Engineering Construction Compressive crusher is the main equipment of rock material crushing and it is widely used in metallurgy and mining industry, building industry, road construction, chemical engineering and silicate industrywhat is crushing in chemical engineeringWhat Is Crushing In Chemical Engineering Chemical engineer article about chemical engineer the science dealing with the processes methods and means for the largescale chemical processing of raw materials and intermediates chemical engineering arose in the late 18th century and until nearly the 1930s it consisted in describing individual chemical production processes and the basic equipment What Is Crushing In Chemical Engineeri Jaw Crusher

Visual Encyclopedia of Chemical Engineering

Material is fed through a feed plate that distributes the particles evenly into the chamber between the mantle and the concave casing The mantle oscillates, causing a decrease in the volume between the mantle and the concave casing and crushing the material The JR BACKHURST, in Chemical Engineering (Fifth Edition), Volume 2, 2002 The gyratory crusher The gyratory crusher shown in Figure 26 employs a crushing head, in the form of a truncated cone, mounted on a shaft, the upper end of which is held in a flexible bearing, whilst the lower end is driven eccentrically so as to describe a circleGyratory Crusher an overview ScienceDirect TopicsCrushing is the first step of mineral processing where t he ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent u sage by(PDF) SIZE REDUCTION BY CRUSHING METHODS

how does chemical engineering related to rock crushing

Visual Encyclopedia of Chemical Engineering Material is fed through a feed plate that distributes the particles evenly into the chamber between the mantle and the concave casing The mantle oscillates, causing a decrease in the volume between the mantle and the concave casing and crushing the material The get priceHowever, due to the crushing board that is easy to wear, it is also limited in the hard material crushing The impact crusher is commonly used for the crushing of limestone, coal, calcium carbide, quartz, dolomite, iron pyrites, gypsum, and chemical raw materials of medium hardnessImpact Crusher an overview ScienceDirect TopicsIn chemical engineering and related fields, a unit operation is a basic step in a processUnit operations involve a physical change or chemical transformation such as separation, crystallization, evaporation, filtration, polymerization, isomerization, and other reactionsUnit operation Wikipedia

Basic Principles and Calculations in Chemical Engineering

Mathematics in Chemical Engineering" within 3rd year of study Chapter 7 A general Strategy for Solving Material Balance Problems The strategy outlined below is designed to focus your attention on the main path rather than the detours: 1 Read and understand the problem statementJul 01, 2015 Crushing is accomplished by compression of the ore against rigid surfaces, or by impact against surfaces in a constrained motion path Grinding (and/or milling, which is a form of grinding) is COMMINUTION: Liberation, Crushing, GrindingIn mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surface Less abrasive and softer rocks or stones Crushing in Mineral Processing

Visual Encyclopedia of Chemical Engineering

A Review on Cryogenic Grinding International Journal of Current Engineering and Technology LePree, J (2018, February) Improving the Daily Grind Chemical Engineering Essentials for the CPI Professional Print Lynch, AJ, Mineral Crushing and Grinding Circuits New York: Elsevier Scientific Publishing Company, 1977and extent of chemical reactions that occu r when the end product is used Crushers are used for the crushing or mediumhard rock as well as fo r sticky and soft materials, ie lignite and m (PDF) SIZE REDUCTION BY CRUSHING METHODSCIVIL ENGINEERING – Vol II by crushing and grinding for the liberation of minerals, separation of mineral particles by va rious principles and a number of operations associated with them However, most of the processes are basically physical (or The chemical Mineral Comminution and Separation Systems

Answered: Why does crushing a solid cause it to bartleby

*Response times vary by subject and question complexity Median response time is 34 minutes and may be longer for new subjects Q: Q1 A singlestage liquid/vapor separation for the benzene and ethylbenzene system must produce phase A: Equilibrium compositions:x1=035, y1=07The Antoine In chemical engineering and related fields, a unit operation is a basic step in a processUnit operations involve a physical change or chemical transformation such as separation, crystallization, evaporation, filtration, polymerization, isomerization, and other reactionsUnit operation WikipediaMathematics in Chemical Engineering" within 3rd year of study Chapter 7 A general Strategy for Solving Material Balance Problems The strategy outlined below is designed to focus your attention on the main path rather than the detours: 1 Read and understand the problem statementBasic Principles and Calculations in Chemical Engineering

In The Crushing Of Rice, The Feed Composition Cont

chemical engineering questions and answers; In the crushing of rice, the feed composition contains 80% of the particles being less than 508 mm in size and the product composition contain 80% of the particles being less than 360 mm For this process, the required power is 114 kW a Calculate the power requirement if the same feed is to be Mar 14, 2021 Grinding definition: If you describe a bad situation as grinding , you mean it never gets better, changes, or Meaning, pronunciation, translations and examplesGrinding definition and meaning Collins English DictionaryCoal chemical mining cement industry Crusher Industry Drives The Development Of Chemica The crushers have been widely applied in many industrial departments such as cement making chemistry power station and metallurgy and for medium and fine crushing all kinds of materials with medium hardness such as limestone slag coke and coal The constant development of the crusher industry also use of crusher in chemical industry

Bond Fc Crushing And Grindig Calculations, British

crushing and grinding calculations larger capacity mobile crusher crushing and grinding calculations – Crusher Manufacturer calculations of a conveyor belt project report Bond, FC 1961Crushing and Grinding Calculations Part I and II, British Chemical Engineering, Vol 6, No 6 and 8 – OneMine Mining and Minerals Library A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedCrusher WikipediaChemical Engineering QA Library Q1: Power of 12kW is supplied to a machine Crushing limestone from 8mm diameter average size to 02 mm diameter average size The same machine is used to crush the same material from 8mm diameter average size to a product consisting of 30 percent with an average diameter of 025mm, 40 percent with an average diameter of 015mm, 20 percent with an average Answered: Q1: Power of 12kW is supplied to a bartleby

COMMINUTION: Liberation, Crushing, Grinding

Jul 01, 2015 Crushing is accomplished by compression of the ore against rigid surfaces, or by impact against surfaces in a constrained motion path Grinding (and/or milling, which is a form of grinding) is Crushing and grinding are the two primary comminution processes Crushing is normally carried out on "runofmine" ore, while grinding (normally carried out after crushing) may be conducted on dry or slurried material In comminution, the size reduction of particles is done by three types of forces: compression, impact and attritionMineral processing WikipediaMay 14, 2010 The ratio of surface energy created by crushing to the energy absorbed by the solid is the crushing efficiency ɳ c if e s is the surface energy per unit area, in feet times pound force per square foot, and A wb and A wa are the areas per unit mass of product and feed, respectively, the energy absorbed by a unit mass of the material W n is W n = e s (A wb A wa)/ ɳ cChemical Engineering Stop: Crushing efficiency

Mineral Comminution and Separation Systems

CIVIL ENGINEERING – Vol II by crushing and grinding for the liberation of minerals, separation of mineral particles by va rious principles and a number of operations associated with them However, most of the processes are basically physical (or The chemical JR BACKHURST, in Chemical Engineering (Fifth Edition), Volume 2, 2002 The gyratory crusher The gyratory crusher shown in Figure 26 employs a crushing head, in the form of a truncated cone, mounted on a shaft, the upper end of which is held in a flexible bearing, whilst the lower end is driven eccentrically so as to describe a circleGyratory Crusher an overview ScienceDirect Topics*Response times vary by subject and question complexity Median response time is 34 minutes and may be longer for new subjects Q: Q1 A singlestage liquid/vapor separation for the benzene and ethylbenzene system must produce phase A: Equilibrium compositions:x1=035, y1=07The Antoine Answered: Why does crushing a solid cause it to bartleby

Basics of Chemical Engineering: UNIT OPERATION

May 26, 2017 In chemical engineering and related fields, a unit operation is a basic step in a process Unit operations involve a physical change or chemical transformation such as separation, crystallization, evaporation, filtration, polymerization, isomerization, and other reactions Mechanical processes, including solids transportation, crushing and Mathematics in Chemical Engineering" within 3rd year of study Chapter 7 A general Strategy for Solving Material Balance Problems The strategy outlined below is designed to focus your attention on the main path rather than the detours: 1 Read and understand the problem statementBasic Principles and Calculations in Chemical EngineeringJan 08, 2020 Forensic engineering is the investigation of property loss and injuries related to failure in materials, components, design and structures These can be minor incidents, such as a crankshaft breaking, or catastrophic events, such as a bridge collapseForensic Engineering: Introduction and Types of Forensic

Home The Action Lab

I graduated with my my PhD in Chemical Engineering in 2014 I currently work as a fulltime engineer However, when the sun goes down, I run my own YouTube channel "The Action Lab" On this channel I do simple to complex experiments to show you how amazing science can beOct 02, 2019 The best chemistry pickup line is sure to set off the reaction for chemical attraction! Here is a collection of cute, corny, funny, and possibly even effective chemistry pick up lines For best effect, wear a lab coat while delivering a chemistry pickup lineChemistry Pick Up Lines to Try on Your CrushCrushing stone chemical reaction mlolongo crushing stone chemical reaction mtm crusher feb 07 2013 stone crusher crushing big stone a crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dust crushers may be used to crusher wikipedia is crushingchemical chemical for crushing rocks and stones

How mechanical weathering (breaking or crushing

Nov 11, 2020 Chemical weathering is a chemical process Dissolution is a physical process The premise is flawed, although there are some aspects that are analogous (analogies are NOT examples) However, the mechanical (physical) breaking of a rock into smalleEngineering Stress True or False Activity In this activity, you will check your knowledge regarding the definition and equation of engineering stress, as presented in the lesson DirectionsEngineering Stress: Definition Equation Video Lesson