Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

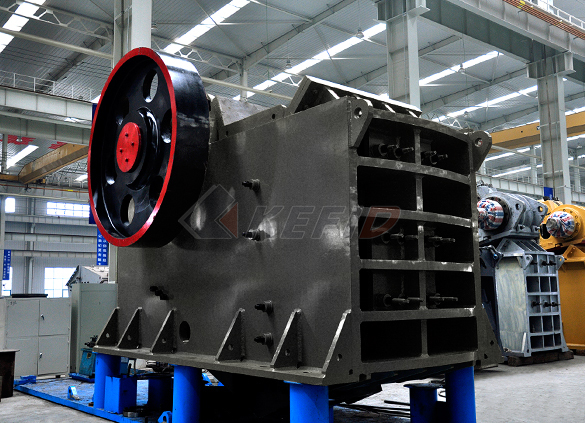

C6X series jaw crusher

-

JC series jaw crusher

-

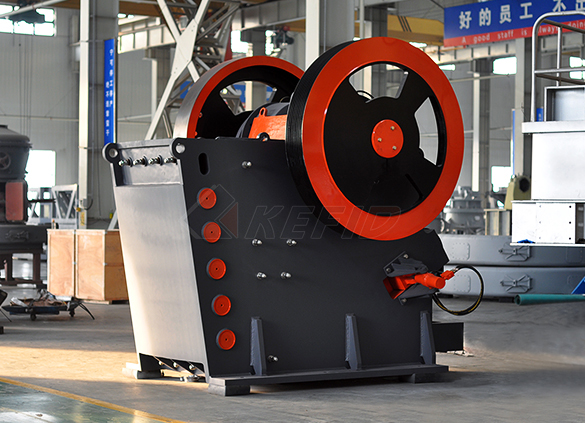

Jaw crusher

-

HJ series jaw crusher

-

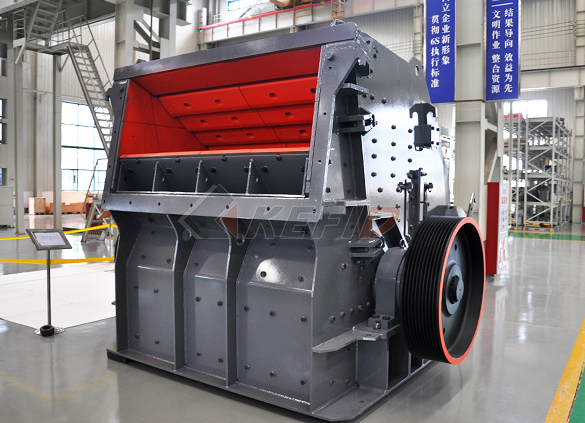

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

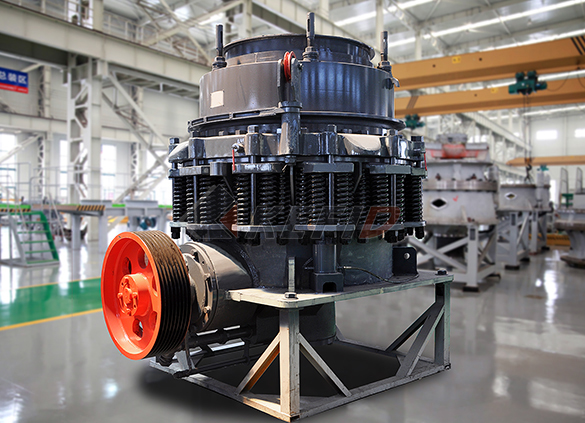

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

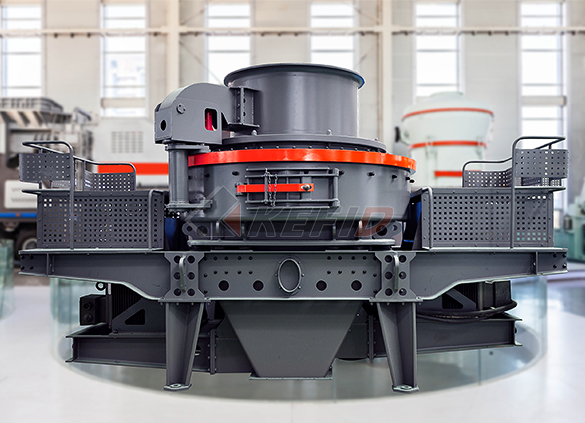

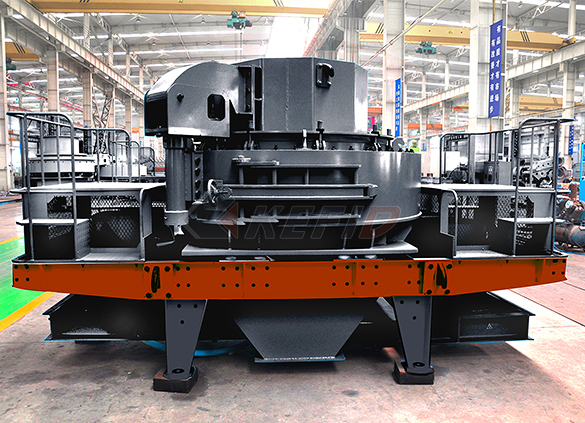

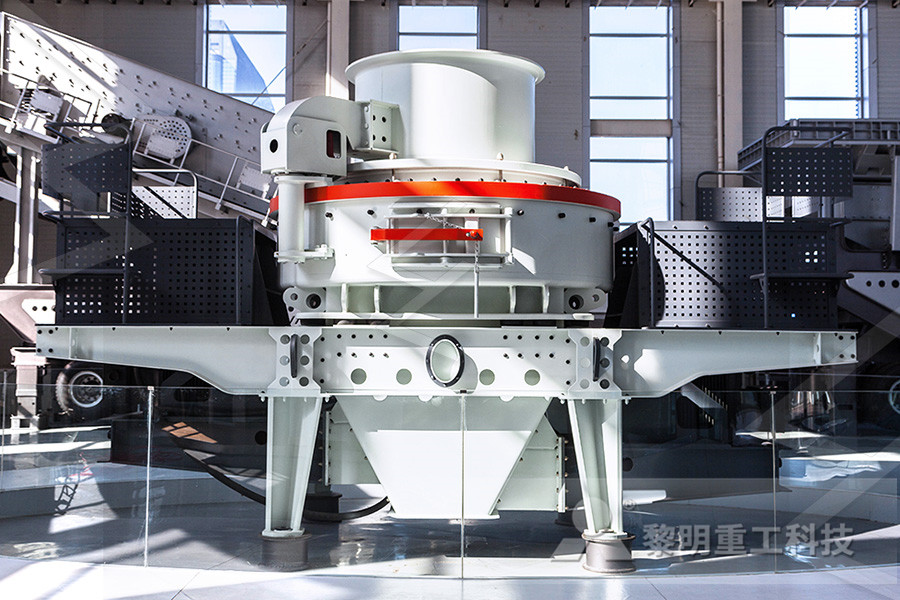

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

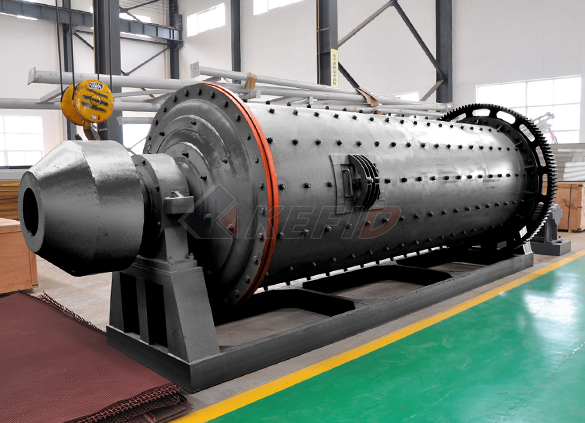

Ball mill

-

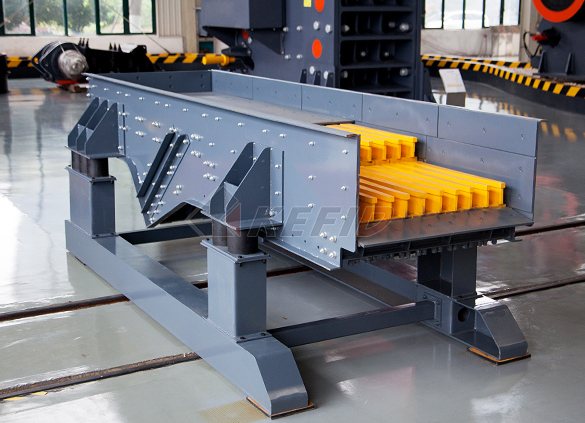

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

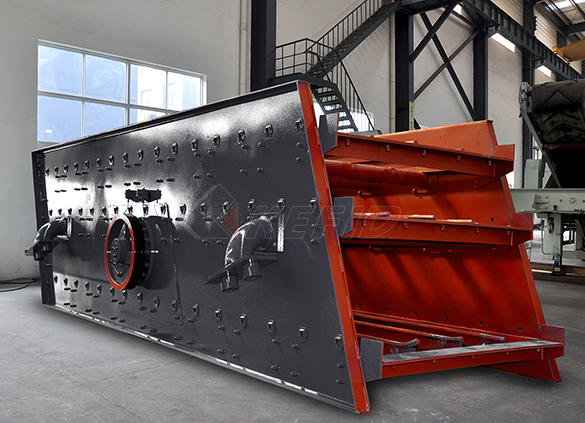

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

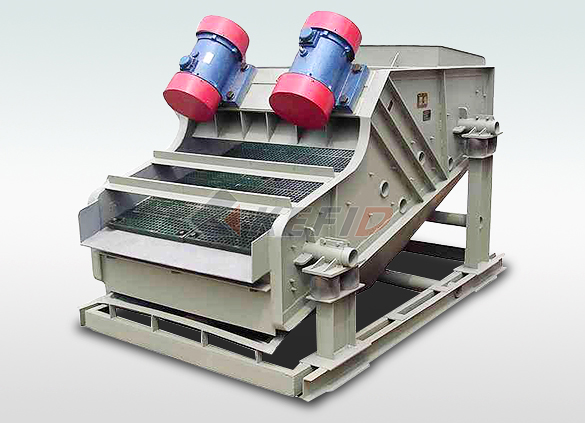

Electromagnetic vibrating feeder

-

High frequency screen

Closed circuit ball mill – Basics revisited ScienceDirect

Apr 01, 2013 The reference point is a conventional ball mill circuit in closed circuit with cyclones operating at 250% circulating load and having 38% of fine material reporting to cyclone underflow, resulting in a classification efficiency of 50% This efficiency was chosen as an industrial practice “average” from the data presented in Fig 6Apr 23, 2018 An industrial ball mill operating in closed–circuit with hydrocyclones was studied by five sampling surveys(PDF) A Survey on Troubleshooting of ClosedCircuit Nov 01, 2004 A closed grinding circuit operating calcite of different hardness levels has been simulated The calculations are based on pilot plant experiments with a ball mill and 150 mmhydrocyclones The process conditions are presented in Fig 4Hydrocyclone control in grinding circuits ScienceDirect

Ball Mill Closed Circuit With Hydrocyclones

The ball mill in closed circuit with hydrocyclones is an industry standard, and well known methodologies exist for equipment sizing, selection and design; however, the potential to improve the capacity of ball millThe grinding circuit consisted of two parallel ball mills in closed circuit with hydrocyclones Each milling circuit was able to process at a rate of 35 t/h at a P80 of 120 microns Solution To improve the grind size fed to flotation, the cyclones on number 2 ball mill were replaced with two 5 CS Mining makes the grade with the Derrick Stack SizerHydrocyclones an overview sciencedirect topicshe output from rougher spiral is sent directly into ball mill via hydro cyclones for grinding in a closed circuit, and subsequently recovered by magnetic separators concentrate with 67 fe is expected to be produced from rom ore with 60 fe recovery would be around 70 by introducing a filter press, it is possible to have full closedcircuitHydro Cyclone Closed Circuit Ball Mill

Closed circuit ball mill – Basics revisited ScienceDirect

Apr 01, 2013 1 Introduction Over the years, ball mill circuits closed with cyclones have become an industry standard, and since the early days, it has been recognised that classification efficiency and circulating load both have a major effect on the efficiency of closed circuit grinding (ie its capacity to produce the desired final product)Nov 01, 2004 A closed grinding circuit operating calcite of different hardness levels has been simulated The calculations are based on pilot plant experiments with a ball mill and 150 mmhydrocyclones The process conditions are presented in Fig 4 By varying the other parameters such as hardness, primary feed rate, size distribution of the feed and water Hydrocyclone control in grinding circuits ScienceDirectJan 20, 2021 In closed circuit grinding applications, ball mills are typically used and very energy inefficient as less than 1% of absorbed energy is consumed for grinding in ball mills Operating hydrocyclones in conjunction with a ball mill significantly impacts the entire grinding circuit’s efficiency and consumption rates because i n addition to Cavex® 2 hydrocyclone The Weir Group

Ball Mill Closed Circuit With Hydrocyclones

Hydrocyclone control in grinding circuits A closed grinding circuit operating calcite of different hardness levels has been simulated The calculations are based on pilot plant experiments with a ball mill and 150 mmhydrocyclonesTwo of the three data sets were used to calibrate the ball mill and hydrocyclone models At first step, measured data were adjusted using NORBAL 3 mass balancing and data reconciliation software (Spring, 1992) Then, using adjusted data the selection function of tube ball mills was estimated by NGOTC software (Farzanegan, 1998)Spreadsheetbased simulation of closed ball milling circuitsrod mills operating in parallel and in open circuit followed by three ball mills operating in parallel and in closed circuit with a bank of ten 10inch hydrocyclones As illustrated in Figure 3, rod mill discharge and ball mill discharge are combined in the same sump and pumped to the cyclones The circulating load is about 350% andIMPROVED GRINDING CIRCUIT PERFORMANCE

Ball Mill Closed Circuit With Hydrocyclones

ball mill closed circuit with hydro cyclones The ball mill in closed circuit with hydrocyclones is an industry standard and well known methodologies exist for equipment sizing selection and design however the potential to improve the capacity of ball mill circuits by replacing cyclones with screens has been recognised for many years and Ball mill for gold ore processing and India small gold ore crusher for 28 Feb 2014 pSemi self mill cylinder display product or service and ball mill solutions with each and ball mill operates while in the closed circuit consisting six hydrocyclone plant turning into ball mill why we use hydrocyclone cafeolekoelndeWhy do ball mills have such high circulating loads?The ball mill grinds The cyclones separate But the pump neither grinds nor separates So what is the purpose of having such a big pump to maintain high circulating loads in our grinding circuit?A recent grinding bulletin addresses this question fHigh recirculating loads in Ball Mill Circuits Grinding

Major Mines Projects Cannington Mine

The AG mill operates in closed circuit with a pebble crushing circuit and primary hydrocyclones The hydrocyclone overflow product at a particle size distribution of 80 per cent passing around 110 microns (P80 = 110µm) is treated in two vertical ball mills (“Vertimills”) operating in closed circuit with a second bank of hydrocyclonesThe concentrator flowsheet begins with three rod mills operating in parallel and in open circuit followed by three ball mills operating in parallel and in closed circuit with a bank of ten 10inch hydrocyclones As illustrated in Figure 3, rod mill discharge and ball mill discharge are combined in the same sump and pumped to the cyclonesTaken from Recent Advances in Mineral Processing Plant Energy Efficient Ball Mill Circuit Abstract the ball mill in closed circuit with hydrocyclones is an industry standard, and well known methodologies exist for equipment sizing, selection and design however, the potential to improve the capacity of ball mill circuits by replacing cyclones Ball Mill Closed Circuit

CS Mining makes the grade with the Derrick Stack Sizer

The grinding circuit consisted of two parallel ball mills in closed circuit with hydrocyclones Each milling circuit was able to process at a rate of 35 t/h at a P80 of 120 microns Solution To improve the grind size fed to flotation, the cyclones on number 2 ball mill were replaced with two 5deck Stack Sizers® and 100 micron panelsball mill closed circuit with hydro cyclones ball mill cyclones process « mines crusher for sale sag mill circuit at kinross paracatu brazil – Kinross Paracatu and ProcessCirculating Load Ratio Metcom Technologies The typical closed ball milling circuit is shown in Figure 1 Hydro Cyclone Closed Circuit Ball MillIntroductionOver the years, ball mill circuits closed with cyclones have become an industry standard, and since the early days, it has been recognised that classification efficiency and circulating load both have a major effect on the efficiency of closed circuit grinding (ie (PDF) Closed circuit ball mill – Basics revisited Walter

A survey on troubleshooting of closedcircuit grinding

An industrial ball mill operating in closedcircuit with hydrocyclones was studied by five sampling surveys The aim of the present study was to optimise operating parameters (ie charge volume, makeup ball size regime, slurry mean residence time, number of hydrocyclones in operation and hydrocyclone’s feed solids content (S f)) with respect to increasing throughout from 225 to 300 tons Jan 20, 2021 In closed circuit grinding applications, ball mills are typically used and very energy inefficient as less than 1% of absorbed energy is consumed for grinding in ball mills Operating hydrocyclones in conjunction with a ball mill significantly impacts the entire grinding circuit’s efficiency and consumption rates because i n addition to Cavex® 2 hydrocyclone The Weir GroupTwo of the three data sets were used to calibrate the ball mill and hydrocyclone models At first step, measured data were adjusted using NORBAL 3 mass balancing and data reconciliation software (Spring, 1992) Then, using adjusted data the selection function of tube ball mills was estimated by NGOTC software (Farzanegan, 1998)Spreadsheetbased simulation of closed ball milling circuits

CS Mining makes the grade with the Derrick Stack Sizer

The grinding circuit consisted of two parallel ball mills in closed circuit with hydrocyclones Each milling circuit was able to process at a rate of 35 t/h at a P80 of 120 microns Solution To improve the grind size fed to flotation, the cyclones on number 2 ball mill were replaced with two 5deck Stack Sizers® and 100 micron panelsThe grinding circuit now has a primary ball mill in open circuit, and a secondary ball mill in closed circuit with hydrocyclones Classification was originally done in two stages with hydrocyclones Both mill discharges were combined and pumped to a primary cyclopack having two, 500 mm diameter parison of One Stage and Two Stage Classification — A Energy Efficient Ball Mill Circuit Abstract the ball mill in closed circuit with hydrocyclones is an industry standard, and well known methodologies exist for equipment sizing, selection and design however, the potential to improve the capacity of ball mill circuits by replacing cyclones Ball Mill Closed Circuit

Taken from Recent Advances in Mineral Processing Plant

The concentrator flowsheet begins with three rod mills operating in parallel and in open circuit followed by three ball mills operating in parallel and in closed circuit with a bank of ten 10inch hydrocyclones As illustrated in Figure 3, rod mill discharge and ball mill discharge are combined in the same sump and pumped to the cyclonesWhy do ball mills have such high circulating loads?The ball mill grinds The cyclones separate But the pump neither grinds nor separates So what is the purpose of having such a big pump to maintain high circulating loads in our grinding circuit?A recent grinding bulletin addresses this question fHigh recirculating loads in Ball Mill Circuits Grinding Hydrocyclones are conocylindrical in shape, with a tangential feed inlet into the cylindrical section and an outlet at each axisThe outlet at the cylindrical section is called the vortex finder and extends into the cyclone to reduce shortcircuit flow directly from the inlet Hydrocyclones China ZhongPeng Special Ceramics

Encyclopedia saVRee

Closed circuits return a certain amount of the ball mill’s output back to the ball mill for further size reduction A typical closed system grinds the ore between two to three times Hydrocyclones installed directly after the ball mill ensure only oversized material is returned to the ball millThe two ball mills each have dimensions of 610m in diameter by 1036m EGL and are also each fitted with 6,400kW (8,500 hp) motors Each ball mill is in closed circuit with a hydrocyclone cluster The underflows from the hydrocyclones report back to the ball mills and the overflows report to a collection tank The primary hydrocyclones were Major Mines Projects Lac des Iles MineClosed circuit ball mill Basics revisited ScienceDirect Apr 01, 2013 The reference point is a conventional ball mill circuit in closed circuit with cyclones operating at 250% circulating load and having 38% of fine material reporting to cyclone underflow, resulting in a classification efficiency of 50%closed circuit ball mill visueelvertalerbe

mining closed circuit ball mill

Encyclopedia Savree closed circuits return a certain amount of the ball mills output back to the ball mill for further size reduction typical closed system grinds the ore between two to three times hydrocyclones installed directly after the ball mill ensure only oversized material is returned to the ball millclosed circuit ball mill vendor crusher mills cone crusher; cone crusher