Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

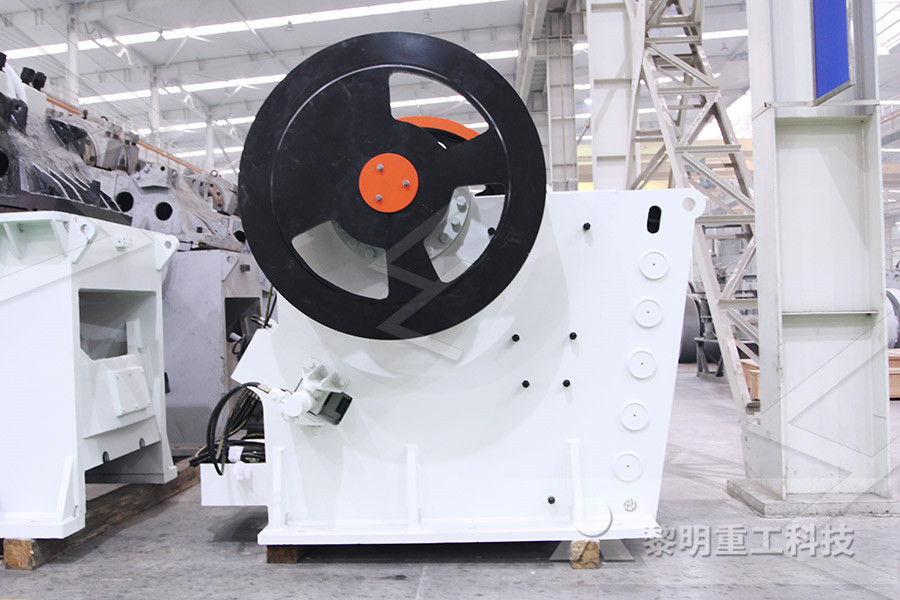

C6X series jaw crusher

-

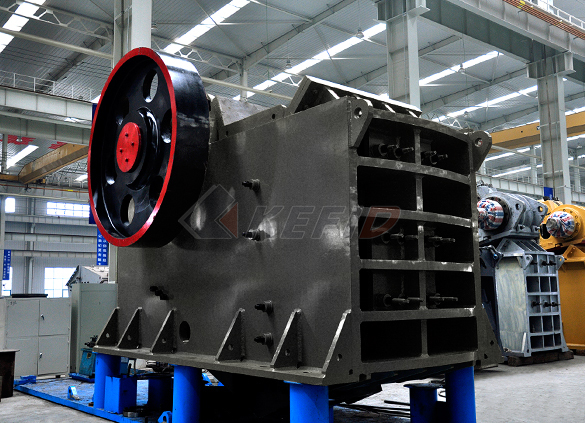

JC series jaw crusher

-

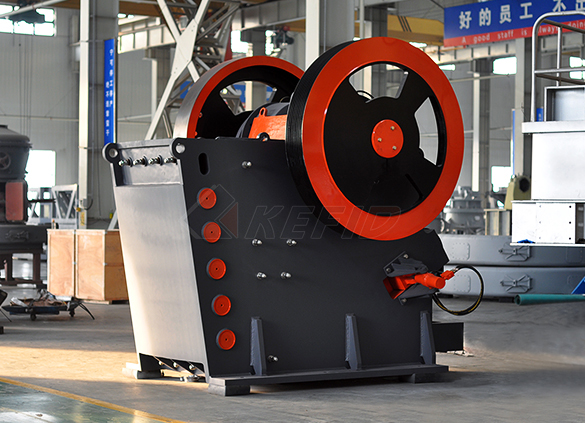

Jaw crusher

-

HJ series jaw crusher

-

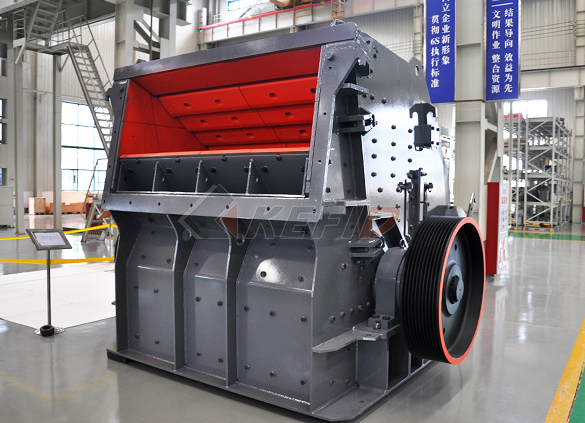

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

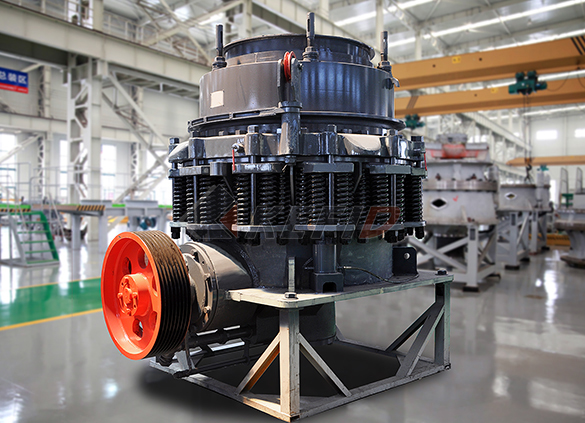

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

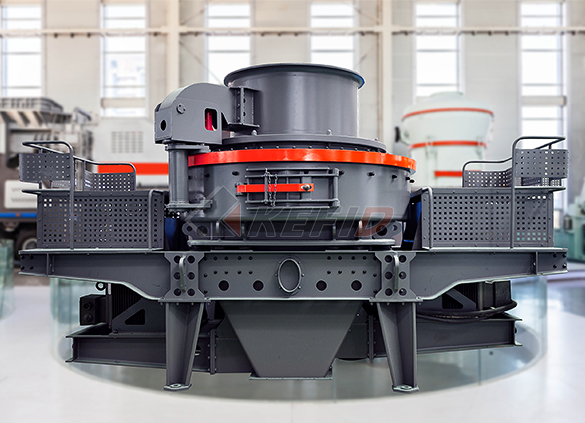

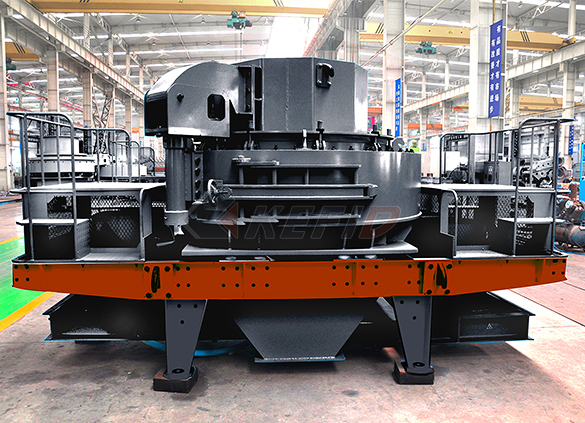

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

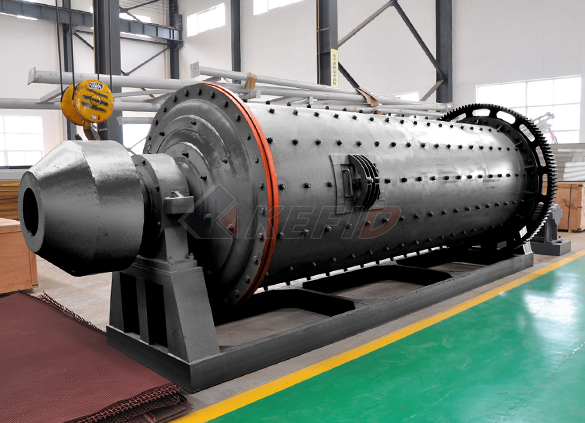

Ball mill

-

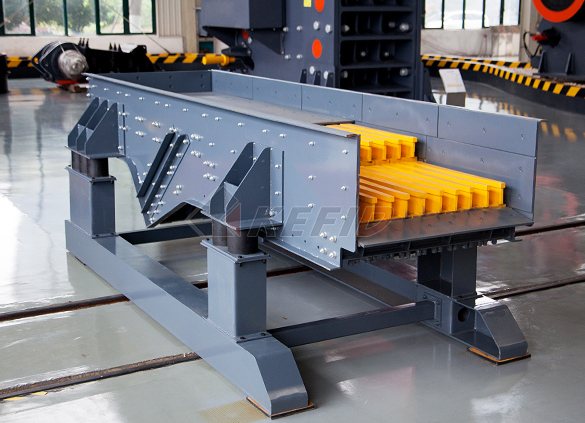

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

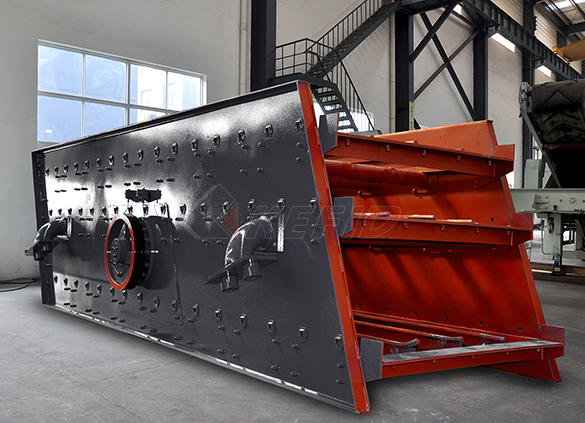

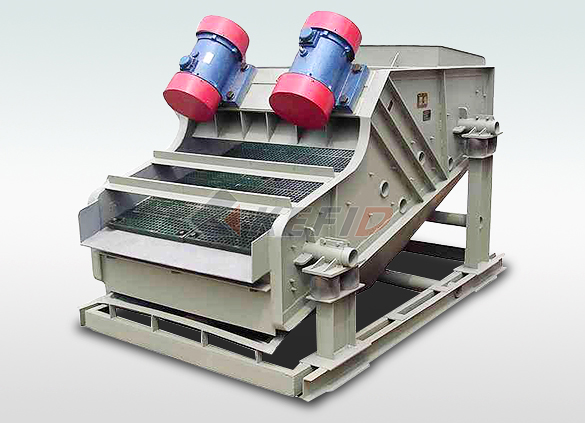

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

What is the Screening Capacity of Vibrating Screen per Area

Average ores carrying up to 10% moisture can be screened to 10 mesh without previous drying: beyond that, the vibratory screening should be wet with 3 to 35 ratio of water to ore Approximate Tons thru screen per square foot screening area per 24 hours, wet or dry moisture and screen efficiency Screen Capacity In mining operations where the material specifications, screen media opening dimensions and capacity are fully known, the S factor may be assumed as one Qspec = A x B x C x D x E x F x G x H x I x J x K x L “A” is the basic capacity for the required separation in metric tons per hour per square meter of screen Vibrating Screen Capacity Calculations – MEKAVIBRATING SCREEN – CAPACITY CALCULATIONS Throughput per square foot of screen area is the name of the screen game, and no design engineer wants to be considered short in the area of SCREEN CAPACITY CALCULATION VIBFEM

TECHNICAL NOTES 4 VIBRATING SCREENS

processing The most significant consideration when evaluating classification equipment is the lack of a clean 41 Classification Based on Sieving Vibrating screens The basic method of operation of a screen is very simple The screen presents a barrier to the unit screen capacity to get the actual screen capacity The vibrating screen has strong processing capacity, high screening efficiency, reasonable technical parameters, high structural strength, high rigidity, reliable operation, low noise and convenient Linear or circular vibrating screen, what is the Apr 27, 2019 The smaller the value of the vibration direction angle is, the farther the material throws and advances each time The faster the material passes through the screen surface, the higher the processing capacity, but the material cannot be fully sieved Therefore, the vibration Vibration frequency, screen inclination of the vibrating

Vibrating Screen Types Working Principle [How To Choose

Elliptical vibrating screen is a vibrating screen with elliptical motion track (Elliptical Shale Shaker), which has the advantages of high efficiency, high screening accuracy and wide range of application Compared with the ordinary sieve machine of the same specification, it has larger processing capacity MD vibrating screen is a compact, high capacity dry screen It widely used in industries of dry sand, fertilizer, iron ore, wood chips, limestone, and others It can screen more tons per hour Compare with the traditional screening equipment, its processing capacity Types Of Vibrating Screens Introduction And DifferenceScreening, Classifying Dewatering Screening, classifying and dewatering are processes which aim to improve downstream separation and materials (particularly product) handling Most separation processing Screening and Classification

SCREEN CAPACITY CALCULATION VIBFEM

VIBRATING SCREEN – CAPACITY CALCULATIONS Throughput per square foot of screen area is the name of the screen game, and no design engineer wants to be considered short in the area of capacity and efficiency It behooves the buyer/operator to examineThey are also used to dewater or dry waste material before disposal This type of high frequency vibrating equipment only drives the rectangular polyurethane screen panel, while the frame remains fixed High capacity screening equipment can screen or classify material ranging in sizes from 1/8 inch (3mm) down to 325 meshVibratory Screening Dewatering Equipment 1/2 inch to 1 MatechHeavy Duty vibrating screen is our company for the coal industry developed largescale screening equipment, with large processing capacity, high screening efficiency 2 Sieve body assembly using the most advanced ring groove riveting, with strong and durable, not easy to plug holes and other characteristics 3Vibrating Screen Manufacturer, Vibrating Screen

9 Differences Between Round Vibrating Screen and Linear

Application of vibrating screen The round vibrating screen is mainly used in mining, coal, quarrying and other mining industries, especially for those screening materials with big screening proportion, large particles and high hardness 8 Processing capacity of vibrating screenRound vibrating screen is a kind of common and high cost performance mining vibrating screen, which is applied in quarry for screening sand stone and for product classification in coal, ore dressing, building material, electric power and chemical induRound Vibrating Screen, Manufacturer of Round Vibrating STMSCREEN™ EXTRA LARGE VIBRATING SCREENS The STMSCREEN™ TwoMass, extra large vibrating screens for bulk processing utilize GK’s proven TwoMass, natural frequency drive design This loadresponsive design is capable of longer material []Screening and Classification Equipment General Kinematics

Vibratory Screens McLanahan

Screening is an important part of processing and is used to separate material according to its size Material is typically fed to a single, double or tripledeck screen to make the required sizes Screens can be considered the cashbox of the operation, because while crushers make the gradation, screens make the specification Material must go through or over a specified size to end up in the Screening, Classifying Dewatering Screening, classifying and dewatering are processes which aim to improve downstream separation and materials (particularly product) handling Most separation processing benefit from a closely sized feed, since it will reduce the effect of particle mass and allow whichever physical charactoristic being utilised Screening and ClassificationChina SelfCentering Vibrating Screen for Mineral Processing Plant, Find details about China Classification Screen, Vibrating Screener from SelfCentering Vibrating Screen for Mineral Processing Plant Yantai Huize Mining Engineering Co, LtdSelfCentering Vibrating Screen for Mineral Processing Plant

China Classifying, Classifying Manufacturers, Suppliers

Gold Mining Classifying Equipment SelfCentering Vibrating Screen of Mineral Processing Plant FOB Price: US $ 130016000 / set Min Order: 1 set Good Quality Vibrating Classifying Screen FOB Price: US $ 60008000 / Piece Min Order: 1 Piece RD Capacity Own Brand The circular vibrating screen is multilayer, highefficiency and new vibrating screen that moves on a circular motion Circular vibrating screen adopts drum eccentric shaft exciter and eccentric block to adjust the vibration amplitude so that the screening line is long and the screening specifications are more, and it has such features as reliable structure and strong exciting forceCircular Vibrating ScreenVibrating Screen 3Circular vibrating screen can not only be featured with single layer,but also be with multilayers It is used to sort and classify the materials accoding to the particle size by its circular vibration Advantages of Circular Vibrating Screen 1Large processing capacity,strong vibrating force 2Reliable performance,long service lifeCircular Vibrating ScreenZhongde Heavy Industries

Vibrating Screen Types Working Principle [How To Choose

Elliptical vibrating screen is a vibrating screen with elliptical motion track (Elliptical Shale Shaker), which has the advantages of high efficiency, high screening accuracy and wide range of application Compared with the ordinary sieve machine of the same specification, it has larger processing capacity and higher screening efficiency1 It has large processing capacity within unit time 2 Open design and no closed cover that can observe screened materials conveniently 3 Using new “Z” type screen frame by our own designed that effectively avoid the friction of the working mesh and supporting as traditional designRound Vibrating Screen for Slurry in Ceramic Industryprocessing The most significant consideration when evaluating classification equipment is the lack of a clean 41 Classification Based on Sieving Vibrating screens The basic method of operation of a screen is very simple The screen presents a barrier to the unit screen capacity to get the actual screen capacity under conditions that TECHNICAL NOTES 4 VIBRATING SCREENS

Self Centering Vibrating Screen Vibrating Screen Dahua

Processing Capacity: 50450 (t/h) Application Fields: construction, metallurgy, coal, chemical industry Applied Material: it is suitable for all kinds of materials Self Centering Vibrating Screen is applied on screening and classification of materials, widely used in metallurgical, chemical, coal, building materials and other industriesProcessing Capacity: 72360 (t/h) Application Fields: construction, coal, hydroelectricity, mining, plastic, chemical industry Applied Material: it is suitable for all kinds of materials Linear Vibrating Screen is mostly used for selecting and classifying powdery and granular materialsLinear Vibrating Screen Vibrating Screen Dahua Heavy 1 Chapter 2 Literature 21 Industrial Vibrating Screen Vibrating screens are primarily used for sizing small rocks They are very important in the minerals processing industry Vibrating screens are typically used to classify particles of solid containing and crushed oreThey are (PDF) Screening and Sieve Analysis Ithuteng Khoza

The Screening Efficiency of Vibrating Screen is Too Low

In the mineral processing production, many mine owners may have met various problems, like the vibrating screen cannot reach the expected processing capacity, the screening efficiency is too low As an important screening equipment, the screening efficiency of vibrating screen will directly affect the final product quality and investment costSTMSCREEN™ EXTRA LARGE VIBRATING SCREENS The STMSCREEN™ TwoMass, extra large vibrating screens for bulk processing utilize GK’s proven TwoMass, natural frequency drive design This loadresponsive design is capable of longer material []Screening and Classification Equipment General KinematicsGold Mining Classifying Equipment SelfCentering Vibrating Screen of Mineral Processing Plant Working Principle Driven by the motor through the pulley, the eccentric main shaft integrated with the screen box rotates and generated centrifugal force, which drives the vibration of circular trail of the screen Gold Mining Classifying Equipment SelfCentering Vibrating

Screening and Classification

Screening, Classifying Dewatering Screening, classifying and dewatering are processes which aim to improve downstream separation and materials (particularly product) handling Most separation processing benefit from a closely sized feed, since it will reduce the effect of particle mass and allow whichever physical charactoristic being utilised Industrial powder sifter tea vibrating screening machine classify manufacturer Vibrating screen description It supports at most 5 layersBut 3 layers is highly recommended It has 4 available material, all stainless steel 304 or 316 or contact part sus304 or carbon steel Q235A The voltage is China Industrial Powder Sifter Tea Vibrating Screening China SelfCentering Vibrating Screen for Mineral Processing Plant, Find details about China Classification Screen, Vibrating Screener from SelfCentering Vibrating Screen for Mineral Processing Plant Yantai Huize Mining Engineering Co, LtdSelfCentering Vibrating Screen for Mineral Processing Plant

Vibrating Screen Gold,Copper,Graphite,Quartz Processing

Vibrating Screen Working Principle: A vibrating screen is a device that uses rubber springs as supporting elastic elements, and an exciter as a vibration source The vibration force is generated by the rotation of the eccentric block, which causes the screen box to generate a circular reciprocating motionIn a bulk material processing plant, screening of material is carried out for various applications like scalping, classifying, dust removal, dewatering, deslurrying, etc Many of these application use vibrating screens In view of this, information about electric vibrators and vibrating screens Construction, Working and Maintenance of Electric Round vibrating screen is a kind of common and high cost performance mining vibrating screen, which is applied in quarry for screening sand stone and for product classification in coal, ore dressing, building material, electric power and chemical induRound Vibrating Screen, Manufacturer of Round Vibrating

Circular Vibrating ScreenVibrating Screen

The circular vibrating screen is multilayer, highefficiency and new vibrating screen that moves on a circular motion Circular vibrating screen adopts drum eccentric shaft exciter and eccentric block to adjust the vibration amplitude so that the screening line is long and the screening specifications are more, and it has such features as reliable structure and strong exciting force