Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

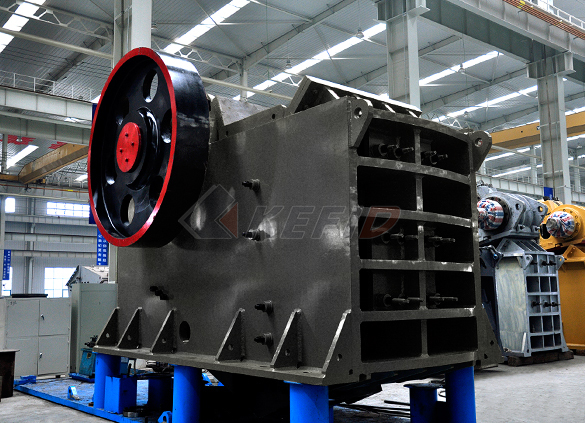

C6X series jaw crusher

-

JC series jaw crusher

-

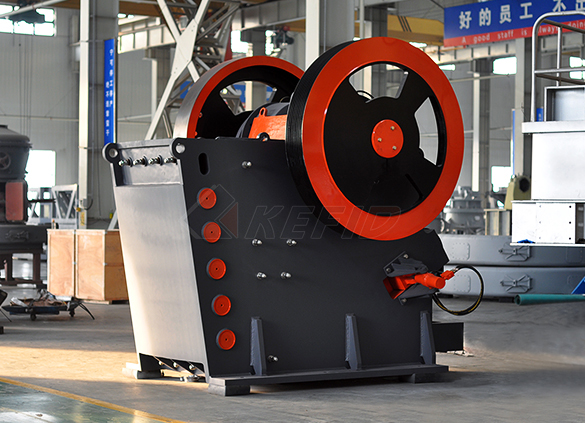

Jaw crusher

-

HJ series jaw crusher

-

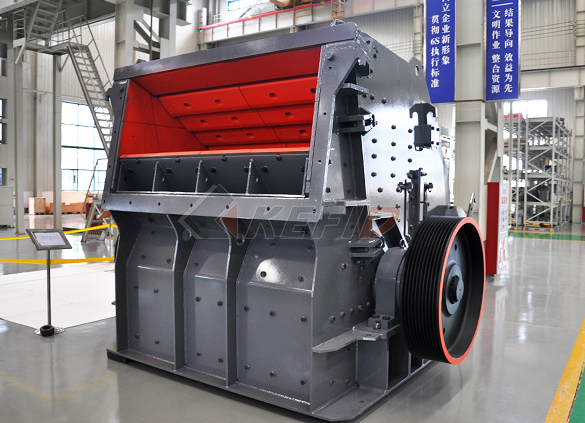

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

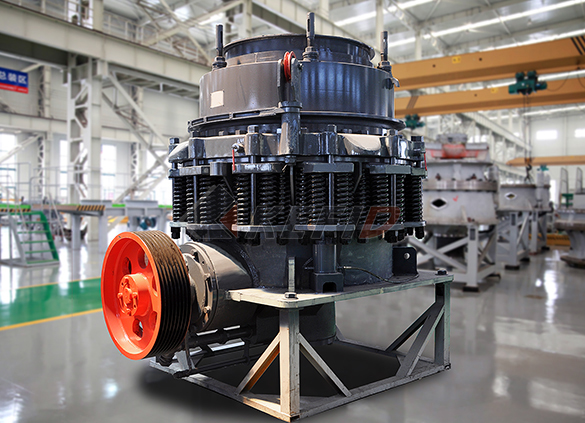

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

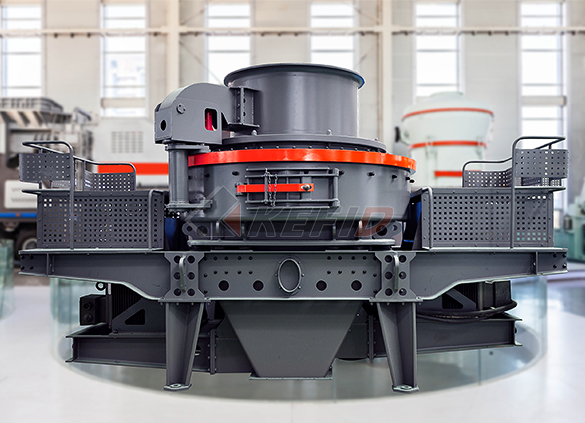

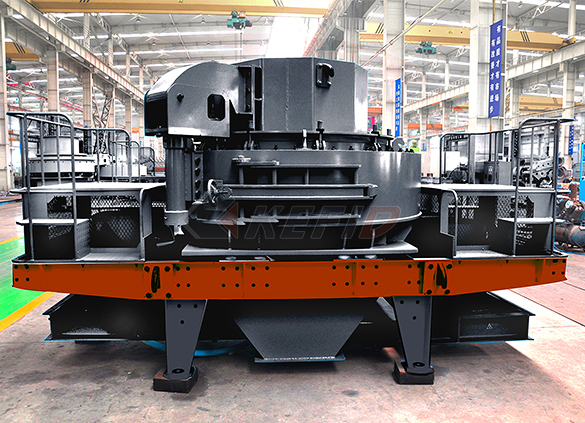

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

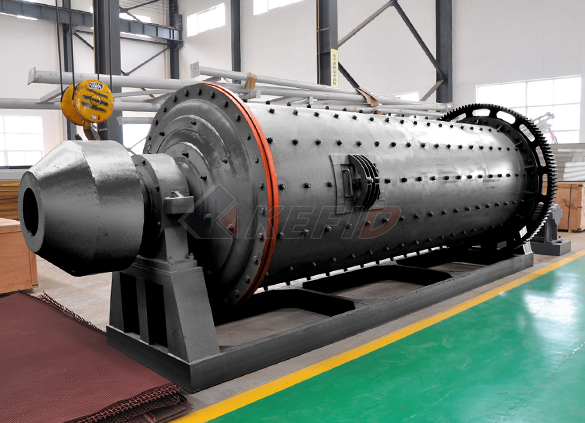

Ball mill

-

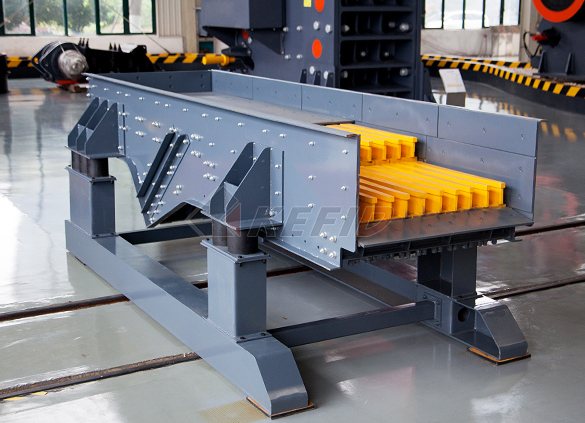

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

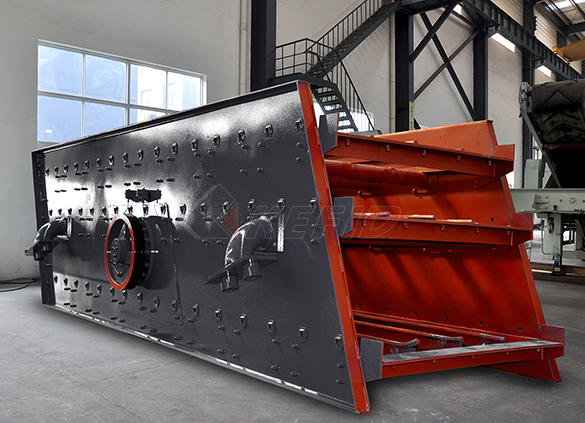

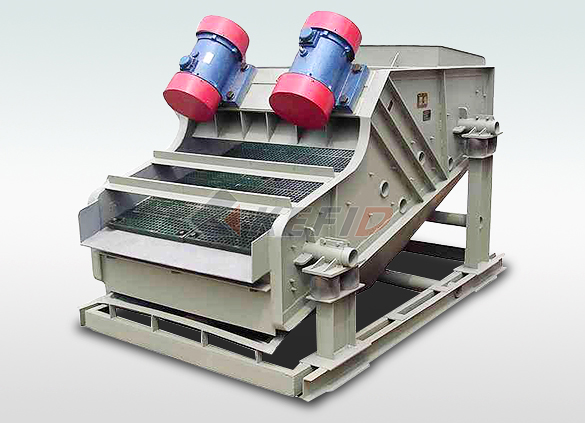

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

How to Determine Needed Air Pressure for Applications

Dec 01, 2019 The Right Air Pressure for Each Application From grinding, chiseling and drilling to sanding, painting and greasing, it’s crucial to have an air compressor that can provide the right amount of air pressure for each applicationSep 01, 2011 In the first set of experiments, air pressure around grinding wheel is measured at a distance of 06 mm from wheel peripheral surface under the conditions of different swivel angles (α =0°, 30°, 50°, 70° and 90°), polar angles (θ =30°, 45° and 60°) and different pneumatic barrier pressure (195, 390, 785 and 1175 kPa), when wheel peripheral velocity is maintained at 209 m/sImproving grinding performance by controlling air flow 2 Grind the specimens at a contact pressure of 40 to 150 kPa on a bonded diamond platen for approximately 60 s or until the exposed surface of each specimen is flat and clean Note that the pressure indicated on the grinding machine gage is usually the incoming air pressure, which is not necessarily equal to the pressure of the specimens Grinding and Polishing ASM International

How to get better grinding performance with pneumatic

grinding chamber at a slightly negative pressure (such as 1 inch of water column) or at neutral pressure so it can assist grinding by drawing the required airflow and the final product out of the chamber For help determining the mill’s pressure drop, you may need to run grinding Aug 11, 2017 For example, a grinding wheel moving at 12,000 sfm (3,657 m/min) requires a nozzle pressure close to 270 psi (186 bar) for the coolant jet to match the wheel speed Lower wheel speeds require lower pressures The chart (below) shows the pressure required for waterbased, synthetic oil and mineral oil coolants to achieve the desired jet speedFactors affecting proper coolant application when grinding 2 Grind the specimens at a contact pressure of 40 to 150 kPa on a bonded diamond platen for approximately 60 s or until the exposed surface of each specimen is flat and clean Note that the pressure indicated on the grinding machine gage is usually the incoming air pressure, which is not necessarily equal to the pressure of the specimens Grinding and Polishing ASM International

Improving grinding performance by controlling air flow

Sep 01, 2011 Air layer pressure around the grinding wheel measured radially outward from the centre of the wheel at 209 m/s wheel velocity with the application of pneumatic pressure of 390 kPa at a pneumatic nozzle position r=110 mm, θ=45° with different swivel angles (α)One theory on crepitus suggests that air pressure within the joint is suddenly altered when the joint is cracked, resulting in the formation or collapse of an air cavity in the synovial fluid that produces a popping sound 1; Ligament or tendon snappingThe Truth About Back Cracking and GrindingAug 11, 2017 Grinding is a thermally dominated process, meaning a high percentage of process heat initially enters the part before coolant quenches it Unless the coolant is applied at the correct flow rate and pressure, and the proper input conditions are selected, this process can lead to undesirable rehardening burn, thermal softening and tensile residual stressesFactors affecting proper coolant application when grinding

In Grinding, Coolant Application Matters

Mar 01, 2008 Recent work using highspeed photography revealed that lowpressure flood coolant was easily deflected by the air barrier, especially when the nozzle jet was aimed directly into the “V” of the grinding zone The air was shown to remain with the wheel and enter the grinding zone, and the coolant was reflected backAir from an external source is connected to the microforge/grinding center and when the foot switch is activated, is directed to an output channel Pressure air from this source can be used for clearing a pipette of dust after grinding, or for expanding or cooling a pipette during forging(MFG5) MicroforgeGrinding Center Warner InstrumentsThe majority of air tools operate in the 90 to 100 psi range and most air compressors from the smallest to the largest can easily produce this much pressure The real deciding factor in selecting the proper size air compressor is the CFM that it can produceAir Consumption Chart for Tools Red Hill Supply

The Effects of Low Barometric Pressure on the Ears

The term "barometric pressure" is often used interchangeably with the terms “air pressure” and “atmospheric pressure,” and refers to the force exerted on you by the weight of tiny air particles, according to NASA If you’re in a lowpressure area, there’s less atmospheric mass and thus less forceExhaust all air pressure from the system before removing air filter/regulator or combination cylinder cover Note : During all testing, the vehicle air pressure must be greater than 90 PSI (620 kPa) If during testing the pressure falls below 90 PSI (620 kPa), make sure the transmission is in neutral, start the engine, and let the pressure Eaton Fuller Transmission Air System TroubleshootingDec 16, 2013 rincon grinding when shifting and correct tire pressure? Jump to Latest Follow 1 19 of 19 Posts And grinding going into gear is not normal Check your oil level, the engine and tranny share the same oil If it were me I would change the oil and make sure that you use JASOMA oil, you never know what the PO used rincon grinding when shifting and correct tire pressure

How to get better grinding performance with pneumatic

grinding chamber at a slightly negative pressure (such as 1 inch of water column) or at neutral pressure so it can assist grinding by drawing the required airflow and the final product out of the chamber For help determining the mill’s pressure drop, you may need to run grinding To check the gauge, you can convert a standard air regulator into a working measurement tool The regulator must have two output ports and one inlet port Fit the inlet port with an air plug that matches the coupler on the air line closest to the grinding or sanding equipment Next, fit a quality air gauge in good condition on one of the outlet Abrasive belt tensioning: Overlooked and underaddressedAn air compressor works by pulling air from the surrounding environment into its storage tank, compressing the air, and keeping it under pressure until the air is released through a pneumatic tool The Best Home Air Compressors for DIY Tools Bob Vila

USA Toilet utilizing air pressure, grinding and

A selfcontained toilet that does not require water for operation and does not require chemicals for operation including a toilet bowl enclosure that is cleaned by compressed air pressure and provides for human waste to be forced down into a heat and grinding chamber that becomes closed off by a sliding door The air pressure comes from an internal compressor and air tank which not only cleans 2 Grind the specimens at a contact pressure of 40 to 150 kPa on a bonded diamond platen for approximately 60 s or until the exposed surface of each specimen is flat and clean Note that the pressure indicated on the grinding machine gage is usually the incoming air pressure, which is not necessarily equal to the pressure of the specimens Grinding and Polishing ASM InternationalGrinding machines Grinding machines Die grinders Airbrush Sandblasting guns Liquid guns Greasing guns Rivet guns Grinding cleaning machines Tapping machines Taps cushions Grinding belts discs Grinding machines Safety shields for machines Workpieces clamping Saw blades and hole saws Sawing machinesGrinding machines Air pressure tools Vynckier tools

Influence of oil mist parameters on minimum quantity

Jun 01, 2010 When air pressure is high (P=7 bar), the tangential grinding forces resulting from the MQL technique (for both Q=50 and 100 ml/h) are higher than those from P=4 bar , due to the smaller oil droplets diameter, higher mist generation in the ambient air and lower lubrication of the contact zone The high air pressure can help in removing the Press Roll Grinding In this application, a ProportionAir QB3 is controlling pressure on two cylinders to control the force of grinding in this pressure roll grinding process The QB3 is controlling the amount of force being applied to a grinding wheel that is refurbishing paper press rollersPress Roll Grinding Force Control by ProportionAirMar 01, 2008 Recent work using highspeed photography revealed that lowpressure flood coolant was easily deflected by the air barrier, especially when the nozzle jet was aimed directly into the “V” of the grinding zone The air was shown to remain with the wheel and enter the grinding zone, and the coolant was reflected backIn Grinding, Coolant Application Matters

1/8inch Micro Pneumatic Air Pencil Die Grinder Kit

️ Cheap 1/8inch Micro Pneumatic Air Pencil Die Grinder Kit Grinding Compressor Tool Air Pressure Grinder Polish Engraving Dremel Tool Details here: https:/Grinding, polishing and other shop type applications require air filtration systems that will be able to sustain its airflow against a significant rise in static pressure This is because collected grinding dust and buffing rouge can plug up inappropriately sized air filters or improperly sized and configured motor/blower combinations resulting The Best Air Cleaners And Dust Collectors For Grinding To check the gauge, you can convert a standard air regulator into a working measurement tool The regulator must have two output ports and one inlet port Fit the inlet port with an air plug that matches the coupler on the air line closest to the grinding or sanding equipment Next, fit a quality air gauge in good condition on one of the outlet Abrasive belt tensioning: Overlooked and underaddressed

High Pressure Grinding Rolls 911Metallurgist

Highpressure grinding rolls were first applied in the minerals industry in 1985 in cement plants The main objective for the use of HPGR was the significant energy savings achievable Today, they are also being used by diamond mines and for the communition of coal as well as for the grinding of slag, iron and chromium concentrates (Figure 4)Compressed air controlled by a foot pedal allows handsfree operation Step on the pedal to instantly close the moving jaw; step again to release it Use these vises in production applications with frequent insertion and removal of workpieces on Bridgeportstyle milling machines and drill presses Vises with a jaw height of 1 1/4 ", 1 5/16 ", and 2 1/2 " can also be used on surface grindersGrinding Vises McMasterCarrThe air pushes the piston for the grinding stroke At the end of the grinding stroke air from the solenoid valve reaches the rear end of the cylinder block The pressure remains the same but the area is less due to the presence of piston rod This exerts greater pressure on the piston, pushing it at a faster rate thus enabling faster return strokePNEUMATIC SOLENOID OPERATED GRINDING MACHINE 2

(PDF) INFLUENCE OF USING REXINEPASTED WHEEL OR

In grinding, high heat is generated at the grinding zone per unit volume of material removed To control this temperature, generally, grinding fluid is employed Due to formation of a stiff air layer around the grinding wheel, grinding fluid cannotGRINDING 46 Pneumatic Die Grinder AIR SONIC Specifications Model Air Pressure Air Consumption (Noload) Free Speed Chuck Size Inlet Size Mass (Weight) Accessories Included MPa (kgf/cm2) m3/min min1(rpm) mm kg L25B 04 27000 06 (without hose) L35C 035 37500 045 (without hose) 06 (6) 6 Rc 1/4 • 14 mm Single Ended Spanner • Mounted GRINDING Nitto KohkiThe TGM tube grinding machine is a handheld, pneumatically driven universal machine for efficient grinding of spherical sealing surfaces The TGM can operate on tubes ranging from 27 to 76 mm diameter and with its diamond grinding wheels grinding is fast and accurateTube Grinding Machine / TGM ChrisMarine