Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

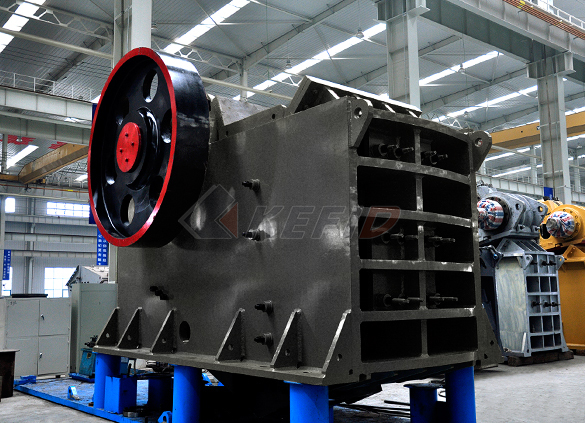

C6X series jaw crusher

-

JC series jaw crusher

-

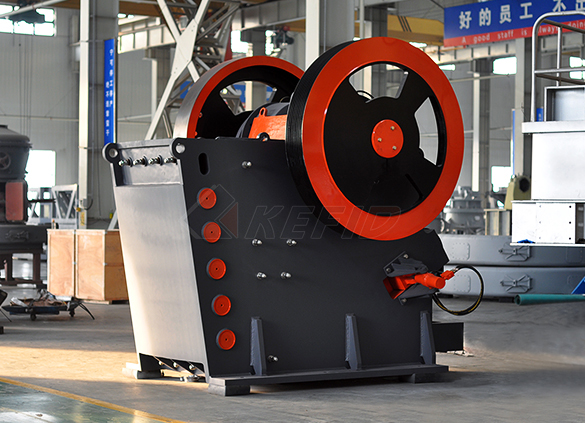

Jaw crusher

-

HJ series jaw crusher

-

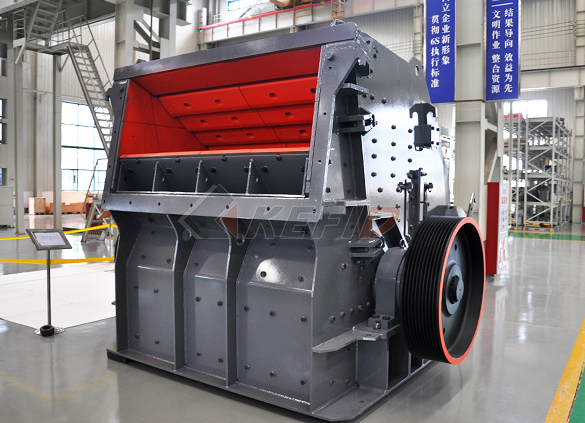

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

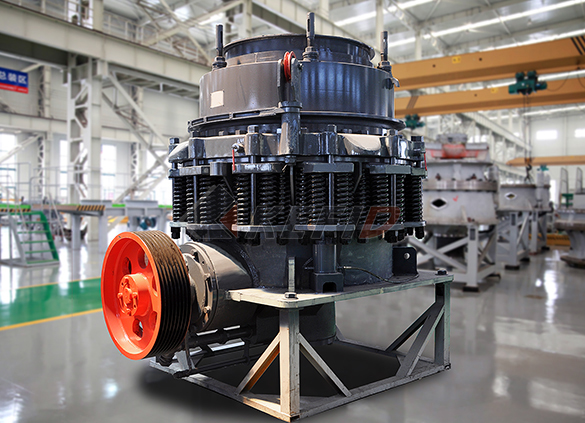

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

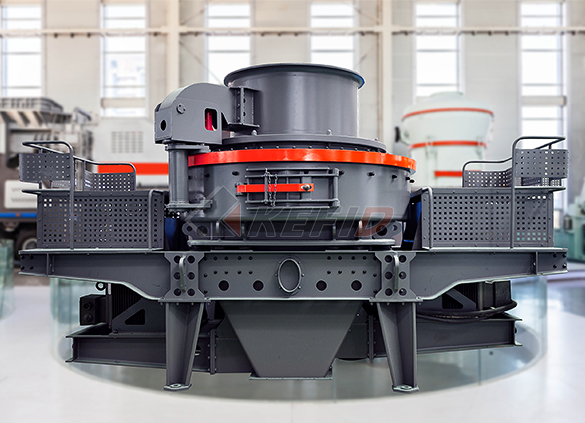

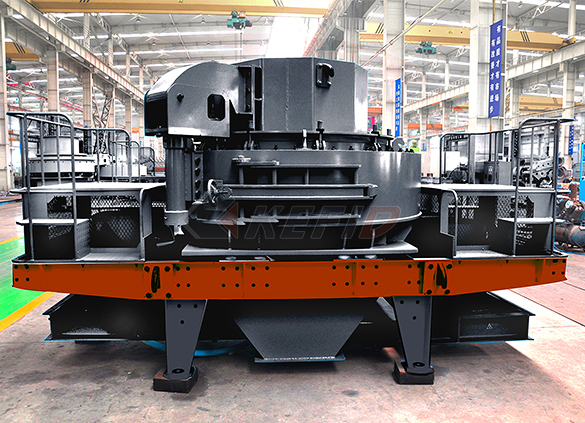

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

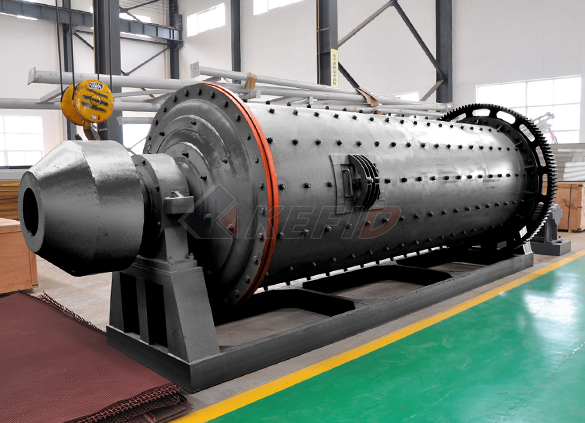

Ball mill

-

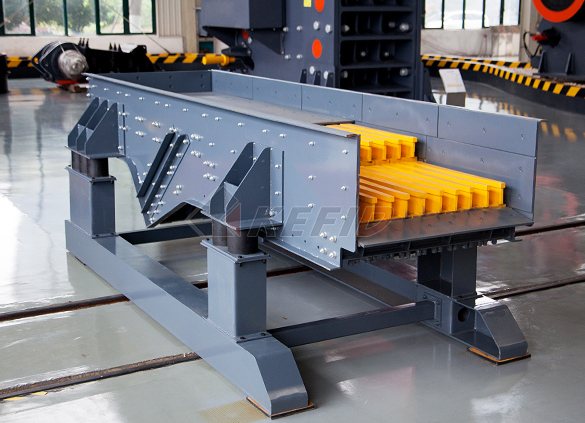

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

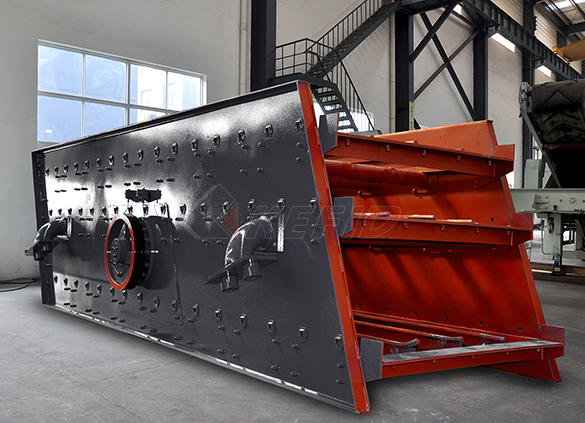

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

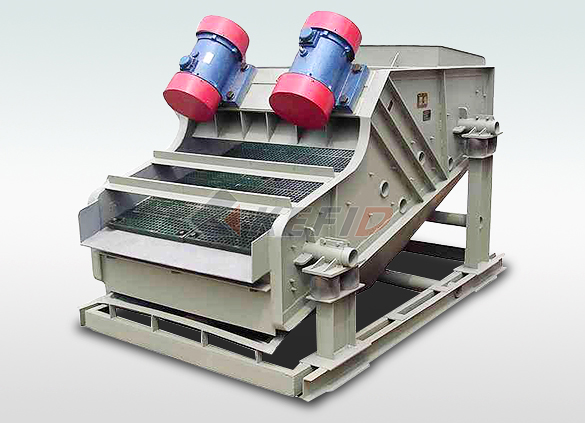

Electromagnetic vibrating feeder

-

High frequency screen

Process Ball Charge Clinker Cement Clinker Cement

The porosity index (p) used in the "Mill Grinding Reference" is: ball charge porosity (p) = average ball weight = kg/ball or lbs/ball Average ball weight is an easy concept to grasp and measure The higher (p) is, the higher is the crushing force and the coarser the ball charge is (p) can be determined by compartment or by the whole millThe proposed model correlates the specific grinding energy, the clinker work index and the specific surface (Blaine) of a cement produced through finegrinding in ball mills Furthermore, a model (PDF) MODELING THE SPECIFIC GRINDING ENERGY AND BALL Feb 01, 2018 In the article attention is paid to improving the efficiency of production of fine powders, in particular Portland cement clinker The questions of Portland cement clinker grinding in closed circuit ball mills Noted that the main task of modeling the grinding process is predicting the granulometric composition of the finished product taking into account constructive and technological Matrix model of the grinding process of cement clinker in

En route to multimodel scheme for clinker comminution

En route to multi model scheme for clinker comminution with chemical grinding aids R K Mishra1, we focus on physical and chemical aspects of grinding Industrial cement ball mills consist of a rotating dual of cement1–4 Most of the earlier work on modelling of clinker grinding clinker and gypsum grinding mills kofutu 2 The ball mill is designed for grinding of clinker gypsum and dry or moist additives to any type of cement The mill may operate En route to a multimodel scheme for clinker comminution arXiv Element Method Grinding aids Fragmentation Ball mill Introduction cement14 Most of the earlier work onhow to ball mill works for clinker grinding model24 rows Cement clinker is usually ground using a cement ball mill This is essentially a large Cement Mill,Cement Clinker Grinding Plant

how grinding ballmill works Pochiraju Industries Ltd

135' X 28' Ball Mills ALLIS CHALMERSKOBE STEEL 18' x 24' Ball 9' x 15' (2745mm x 4570mm) Regrind Ball Mill KURIMOTO IRON WORKS LTD Get Price how grinding ball mill worksThe ground material is transported up by the bucket elevator to the separator After separating, the materials that do not meet the particle size requirements are transported from the air chute to the ball mill for regrinding The dust of the ball mill is transported to the dust collector by the pipelineClinker Grinding Unit cement plant,ball mill,vertical Feb 01, 2014 The revised model can express the grinding process of CKP mill on cement clinker The parameter a (min − 1) reflects the material property grinding by CKP mill There is a linear relationship between the value of the grinding rate and the logarithm value taking 10 as base of the particle size Download : Download highres image (181KB)Effects of circulating load and grinding feed on the

Cement Plant Widely Apply Clinker Mill,Cement Grinding

cement ball mill, Clinker Mill,Cement Grinding mill ball mill A pplication: Raw meal and Cement Ball mill machine is the key equipment in cement factory and other grinding powder field, ball mill is widely used to grinding raw meal, clinker, slag, sand,etc, such as cement, silica, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and In the article attention is paid to improving the efficiency of production of fine powders, in particular Portland cement clinker The questions of Portland cement clinker grinding in closed circuit ball mills Noted that the main task of modeling the grinding process is predicting the granulometric composition of the finished product taking into account constructive and technological Matrix model of the grinding process of cement clinker in Cement ball mill is not only suitable for overflow grinding, but also applicable for cyclic closeflow grinding together with powder collector There are two ways of grinding: the dry way and the wet way Features 1 Can work with grinding and drying equipment simultaneously 2 Easy to adjust the fineness of grinding products 3Cement Ball Mill

(PDF) Clinker grinding process and cement properties

Clinker grinding process and cement properties improvements by additives Ball mill Input energy Generalization of the previously suggested matrix model of grinding En route to multi model scheme for clinker comminution with chemical grinding aids R K Mishra1, we focus on physical and chemical aspects of grinding Industrial cement ball mills consist of a rotating dual of cement1–4 Most of the earlier work on modelling of clinker grinding was focused on the simulation of theEn route to multimodel scheme for clinker comminution Nov 01, 2004 Based on the above considerations for crushing and grinding, the energy consumption for the clinker precrushing and ball milling can be estimated using the following Bond based model: (9) W = W c + W m As precrushing product size P c is equal to the mill feed size F 80 then: (10) W = A F 80 W i 10 P 8010 F c + 13 ∗ 244 D 02 ∗ R r + (W Cement grinding optimisation ScienceDirect

China Easy Operation Clinker Ball Mill for Grinding

1Product Application The ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powdermaking production line including cement, silicate, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc,and the ball mill can grind various ores and other materials with dry type and The multisegment ball mill model developed by Whiten and Kavetsky has been used together with an extensive range of data from operating mills to establish the parameters of a new ball mill model (PDF) Analysis of ball mill grinding operation using mill 135' X 28' Ball Mills ALLIS CHALMERSKOBE STEEL 18' x 24' Ball 9' x 15' (2745mm x 4570mm) Regrind Ball Mill KURIMOTO IRON WORKS LTD Get Price how grinding ball mill workshow grinding ballmill works Pochiraju Industries Ltd

Ball Mills an overview ScienceDirect Topics

The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter ( Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightChanderpur Works Private Limited Offering Clinker Grinding Ball Mill, बॉल ग्राइंडिंग मिल, Ball Mill in Jorian, Yamuna Nagar, Haryana Read about company Get Clinker Grinding Ball Mill, बॉल ग्राइंडिंग मिल in Jorian 3D model of a raw mill Raw mill Ø 54 x 11 m with a predrying chamber Example of a fl ow sheet of raw mill grinding circuit 2 4 6 8 1 – ball mill 2 – elevator 3 – separator VTP 4 – separating cyclone 5 – mill fan 6 – separator fan 7 – clinker bin material 8 – gypsum bin Ball Mills PSP Eng

Cement Grinding Rockwell Automation

the Cement Grinding Application, based on multivariable model predictive control (MPC) technology, has (vertical mill or ball mill) circuit 2 Cement Grinding Overview grindability of clinker or changes in grinding aid compositionPlanetary Ball Mills are used wherever the highest degree of fineness is required QUOTE REQUEST MORE INFORMATION: retsch/pm100In addition Wet Grinding in Planetary Ball Mills RETSCH YouTubePredictive Controller Design for a Cement Ball Mill Grinding Process under Larger Heterogeneities in Clinker Using StateSpace Models Sivanandam Venkatesh , Kannan Ramkumar * and Rengarajan Amirtharajan * School of Electrical Electronics Engineering, SASTRA Deemed University, Thanjavur 613 401, India; edictive Controller Design for a Cement Ball Mill

Matrix model of the grinding process of cement clinker in

In the article attention is paid to improving the efficiency of production of fine powders, in particular Portland cement clinker The questions of Portland cement clinker grinding in closed circuit ball mills Noted that the main task of modeling the grinding process is predicting the granulometric composition of the finished product taking into account constructive and technological En route to multi model scheme for clinker comminution with chemical grinding aids R K Mishra1, we focus on physical and chemical aspects of grinding Industrial cement ball mills consist of a rotating dual of cement1–4 Most of the earlier work on modelling of clinker grinding was focused on the simulation of theEn route to multimodel scheme for clinker comminution Jan 24, 2019 During the grinding of OPC clinker in lab ball mill, the grinding aids are added with the ratios 0, 003, 004 and 005 wt % of the and build upon your work noncommercially The influence of Triethanol amine and ethylene glycol on the grindability, setting and hydration and ball mill surface via the hydroxyl groups which neutralize The influence of Triethanol amine and ethylene glycol on

Cement mill Wikipedia

A Ball mill is a horizontal cylinder partly filled with steel balls (or occasionally other shapes) that rotates on its axis, imparting a tumbling and cascading action to the balls Material fed through the mill is crushed by impact and ground by attrition between the balls The grinding media are usually made of highchromium steelThe smaller grades are occasionally cylindrical ("pebs Typical Ball Mill Circuit For Cement Finish Grinding Price Process Control Of Cement Grinding Ball Mill Ball Mill In Cement Process The cement manufacturing process is illustrated in Fig 1 The final step in manufacture of cement consists of grind ing cement clinker into cement powder Ball mills are used for grinding the cement clinkers The cement mill circuit consists of a ball mill and a Slag Grinding Ball Mill Grinding Ball Mill Ball MillGrinding in Ball Mills: Modeling and Process Control Cybernetics Grinding in ball mills is an important technological process applied to reduce the ware rate, influence on the particle breakage rate and energy efficiency of the grinding aimed at increasing the grinding efficiency of the overall process Read morehow to increase ball mill grinding rate

cement grinding calculations in ball mills

Please can anyone give me, step step by procedure on how to work out on cement ball mills to Cement clinker, Ball mill, Dry grinding, Specific energy cement mill grinding media design calculation Optimization of the makeup ball charge in a grinding mill on ResearchGate, the model of ball wear in a grinding mill leads to a cement ball mill, Clinker Mill,Cement Grinding mill ball mill A pplication: Raw meal and Cement Ball mill machine is the key equipment in cement factory and other grinding powder field, ball mill is widely used to grinding raw meal, clinker, slag, sand,etc, such as cement, silica, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and Cement Plant Widely Apply Clinker Mill,Cement Grinding Clinker Grinding Ball Mill Roller Mills Used Ball Mill For Clinker Grinding 130 Tph Clinker Grinding Ball Mills D A cement mill or finish mill in north american usage is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementst cement is currently ground in ball mills and also vertical roller mills which are more effectiveUsed Ball Mill For Clinker Grinding

Clinker Grinding Unit at Best Price in India

We provide high performing Clinker Grinding Plant that is ideal for the efficient grinding of the clinker to produce cement Our Cement Clinker Grinding Plant is comprised of Precrusher, feed hopper, Table feeders, Material Handling equipment, Ball mill, Blending and Packing Plant Our Cement Clinker Grinding Plant is availableWe are executing grinding mill manufacturing clinker grinding mills and plant in all over the India through a leading grinding mill manufacturer chanderpur works material is fed from hoppers to ball mill to reduce the size to micronscement clinker grinding mill cement grinding ball millBall Mill Working Video The Handling Materials and Application of Ball Mill: Ball mill is used for the grinding work of the crushed ore According to the different materials and discharging methods, there are gratetype ball mill and overflow ball mill for choiceBall Mill Price/ Grinding Ball Mill Manufacturer/ Ball

China Easy Operation Clinker Ball Mill for Grinding

(2) The ball mill is used to grind many kinds of ore and other materials, or to select ore (3) Ball mill is widely used in building material, and chemical industry (4) There are two ways of grinding: dry way and wet way (5) Ball mill can be divided into tabular type and flowing type according to different expelling mine 4Our srrvicePredictive Controller Design for a Cement Ball Mill Grinding Process under Larger Heterogeneities in Clinker Using StateSpace Models Sivanandam Venkatesh , Kannan Ramkumar * and Rengarajan Amirtharajan * School of Electrical Electronics Engineering, SASTRA Deemed University, Thanjavur 613 401, India; edictive Controller Design for a Cement Ball Mill