Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

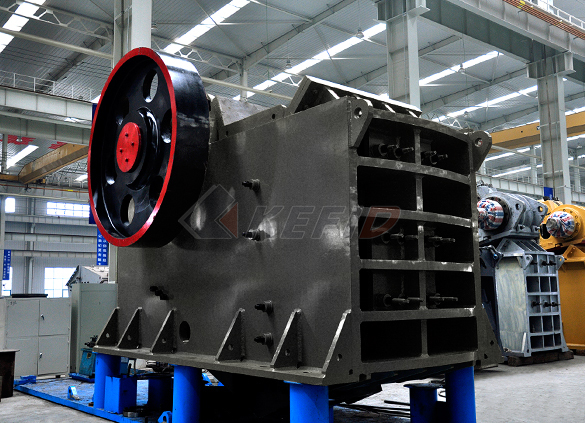

JC series jaw crusher

-

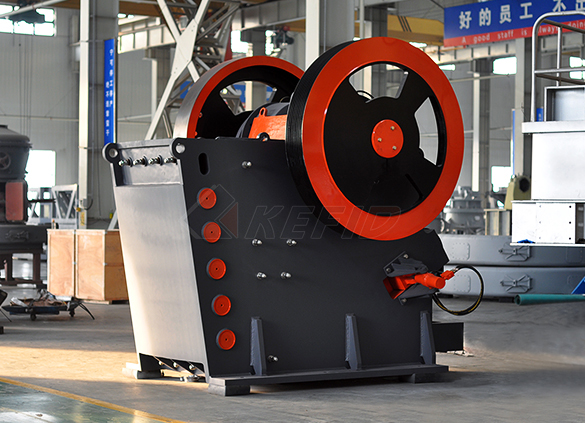

Jaw crusher

-

HJ series jaw crusher

-

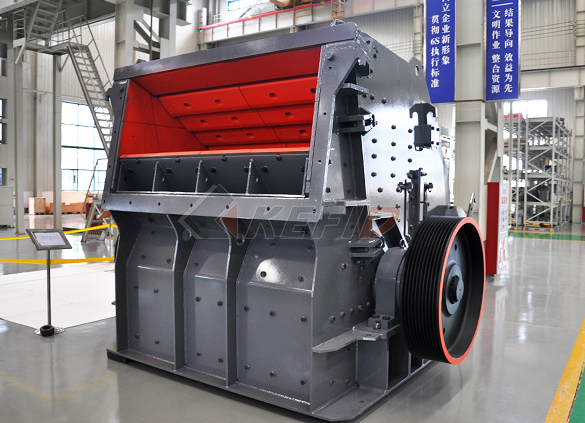

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

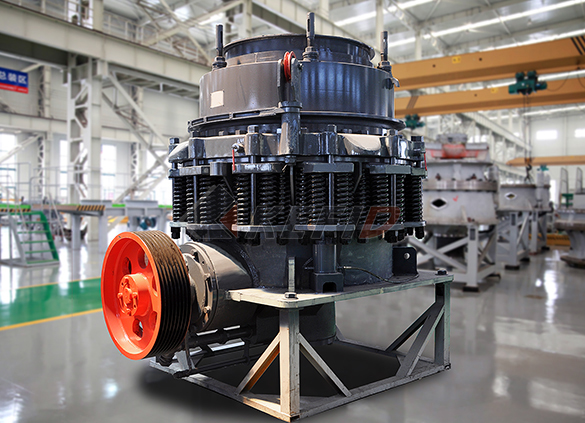

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

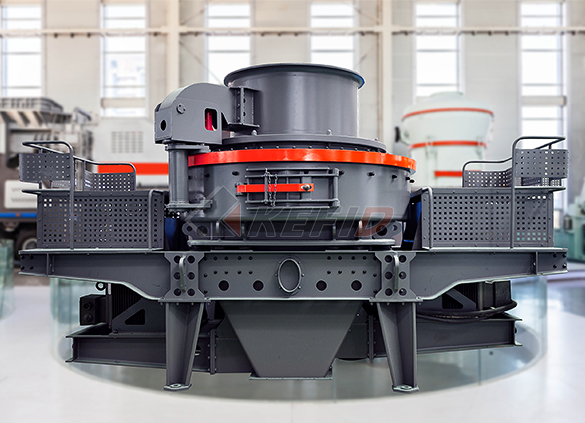

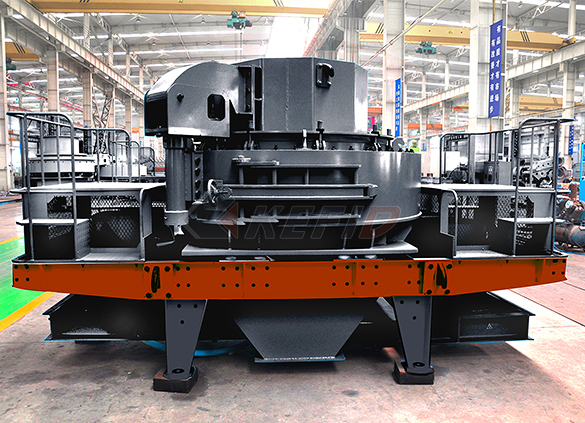

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

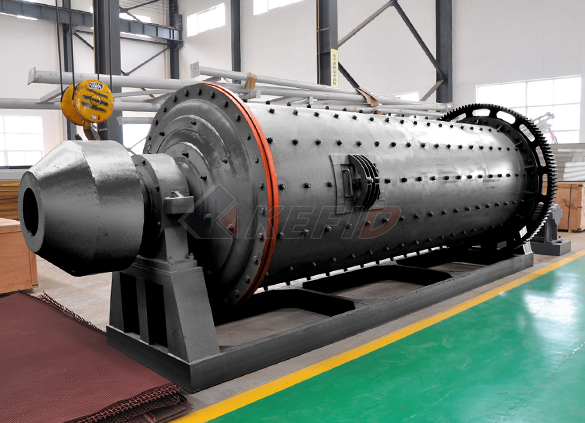

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

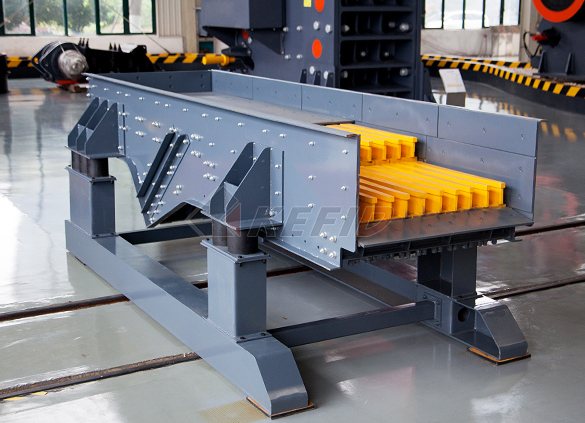

TSW series vibrating feeder

-

Vibrating feeder

-

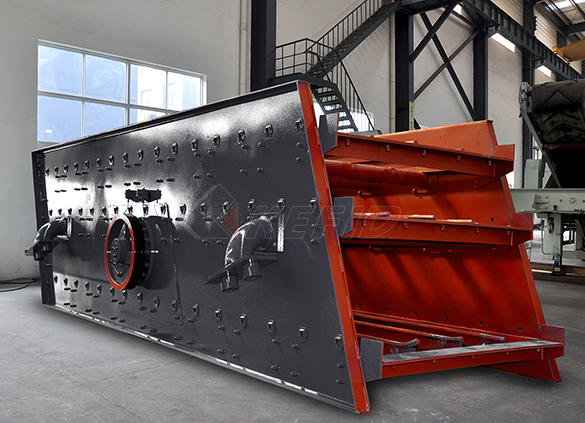

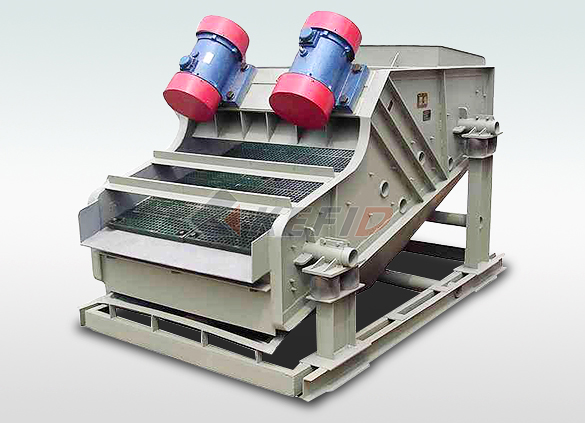

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

HRC™ Series high pressure grinding rolls (HPGR)

High pressure grinding rolls (HPGR) are used for size reduction or rocks and ores They compress the feed material between two rotating rollers, one of which is in a fixed position and another roller that is floating The two rotating rollers generate such a high pressure that it grinds the feed material to the desired smaller grain sizeSep 25, 2019 Our HPGR Rolls utilizes the principle of high pressure inter particle comminution to grind various types of ore, industrial minerals, or clinker for cement production Using our proprietary edge, stud and roll design and unique state oftheart wear technology, a CSP HPGR Roll consumes less energy resulting in reduced operational costs and HIGH PRESSURE GRINDING ROLLS (HPGR) Cast Steel ProductsProfessional High Pressure Grinding Ball Mill For Ore Influence of feed moisture on high pressure grinding roll High pressure grinding rolls HPGR have been used for more than 20 years to grind iron ore pellet feed Besides coarse comminution crushing where HPGR are installed upstream of the ball mill there are numerous flow sheets where HPGR are used after ball milling and dewatering for re orHigh Pressure Grinding Rolls Barite

(HPGR) high pressure grinding rolls/rollers for cement

The HPGR (high pressure grinding rolls/rollers) is the core equipment of the high pressure grinding process The machine reduces particles by compressing and crushing the feed between two counter rotating, parallel rollers with a small gap between themThe Enduron HPGR mechanism involves interparticle grinding, achieved through the action of two counter rotating rolls that compress the feed bed, enabling particles to grind one anotherRolling the competition Australian MiningEssentially a rolls or HPGR crusher consists of two parallel rotating rolls turning together (in opposite directions and turning in the direction of the downward material flow through the centre), with feed being directed through the moving gap between them One roll is fixed, and the other moveable, using hydraulic pressureRoller Crusher,HPGR Crusher for Sale

HPGR in the Iron Ore Industry METS Engineering

HPGR in Iron Ore Processing • Applied to iron ore industry mainly for regrinding of pellet feed to improve properties in the pelletising process • Over time has been applied to other iron ore processes to improve concentrates • Australia − Magnetite (Karara) − Vanadiferous, Titaniferous Magnetite (Future: Mount Peake) • South AfricaUsed in mining applications for the last 30 years, high pressure grinding rolls (HPGR) reduce particles by compressing and crushing the feed between two counter rotating, parallel rollers with a small gap between them a goto for greenfield projects looking to maintain their margins despite commodity price pressures and declining ore gradesHPGR High Pressure Grinding Rolls WeirHRC™3000 is a new generation highpressure grinding roll that eliminates issues found in traditional HPGRs, allowing the mining industry to reach a new level of energy efficiency The world's largest HPGR was installed at FreeportMcMoRan’s Morenci site in Arizona, USAHRC™ Series high pressure grinding rolls (HPGR)

High Pressure Grinding Rolls 911Metallurgist

HPGR roll diameters typically range from 05 m to 28 m, depending on the supplies, and roll widths vary from 02 m to 18 m The aspect ratio of the rolls also varies as a function of manufacturer Typical HPGR throughput rates range from 20 to 3,000 tph, with installed motor power as high as 3,000 kW per rollHPGR or highpressure grinding rolls have made broad advances into nonferrous metal mining The technology is now widely viewed as a primary milling alternative, and there arc a number of large installations commissioned in recent years After these developments, an HPGR based circuit configuration would often be the base case for certain ore types, such as very hard, abrasive ores HPGR High Pressure Grinding RollsThe rolls are protected with wearresistant surfaces, and the ore is contained at the roll edges by cheek plates Applications of HPGR machine The HPGR machines is ideal for crushing hard rock with relatively low moisture content and can provide superior results in the size reduction of a variety of mineralsHigh Pressure Grinding Roll Technology,HPGR for Ore Processing

HighPressure Grinding Rolls,HPGR Machine for Sale

Highpressure grinding rolls (HPGRs) have struggled for acceptance into the hardrock mining sector only hardrock applications that have been in existence for any length of time are restricted to the diamond and iron ore (pelletfeed) sectors Another consideration is that the HPGR is a very rare breed of machine, in that its development The HPGR (high pressure grinding rolls/rollers) is the core equipment of the high pressure grinding process The machine reduces particles by compressing and crushing the feed between two counter rotating, parallel rollers with a small gap between them This forces the rocks against each other and compresses the feed’s density to 80% of its solid [](HPGR) high pressure grinding rolls/rollers for cement to enhance grinding productivity of the HPGR — High pressure grinding rolls in mineral processing Moving from cement to hard rock High pressure grinding rolls (HPGRs), also known as roller presses, are rapidly gaining acceptance in hardrock processing, primarily due to their energy efficiency when reducing mineral ore to fragmentsDrive systems for high pressure grinding rolls RollXtend

River Gold Hpgr Rolls whiskylordde

High Pressure Grinding Rolls HPGR mining SGS barite mining HPGR in Malaysia is a mature technology Compared with other crushing technologies, HPGR is a mature technology Compared with other crushing technologies, smallscale locking cycle test (such as bond ball mill grindability test) can reduce the capital and operating costs of fullscale Fri Barite Ore Grinding Plant Fri barite ore grinding plant barite mineral grinding machine small portable rock crusher mobile cone crusher mobile cone crushing plant is usually a newly created rock crushing amp screening plant, which is widely used in mining, building material, highway, rail way and hydraulic industries, etc mobile cone crusher has basic functions of crushing and screening high perssure barite grinding mill widely used in miningChange of roller press or HPGR roll bodies HPGRs, also known as roller presses, are used in Mauritania for the processing of iron ore A roller typically consists of a base body (shaft) to which a roll body in combination with a wear protection system is attached The surface of the roll bodies is subject to heavy abrasion during operation Change of roller press or HPGR roll bodies TAKRAF GmbH

Lead Zinc Ore Hpgr Rolls In Ethiopia

Lead Zinc Ore Hpgr Rolls In Ethiopia FOB Reference Price: Get Latest Price We have Lead Zinc Ore Hpgr Rolls In Ethiopia,Base metals such as nickel zinc copper and lead are widely used in various industrial and commercial applications copper as a base metal is widely used in infrastructure and electrical applications whereas nickel and zinc are used in iron ore extraction and refiningMost barite is ground to a small, uniform size before it is used as a filler or extender, an addition to industrial products, or a weighting agent in petroleum well drilling mud specification barite HPGR High Pressure Grinding Rolls HPGR or highpressure grinding rolls have made broad advances into nonferrous metal miningSaving Energy Roll Mining Mill Is Used To Crush Barite OreAug 07, 2019 As a single HPGR unit only uses 08 25 kWh per tonne of material, they not only saving you money but freeing up capacity for downstream milling Microcracking improves mineral liberation The high pressure of HPGR’s “bedbreakage” creates microcracks in the ore, promoting improved mineral recovery at coarser size fractionsWhy HPGRs are revolutionising mill circuits

HRC™ Series high pressure grinding rolls (HPGR)

HRC™3000 is a new generation highpressure grinding roll that eliminates issues found in traditional HPGRs, allowing the mining industry to reach a new level of energy efficiency The world's largest HPGR was installed at FreeportMcMoRan’s Morenci site in Arizona, USAHigh Pressure Grinding Rolls (HPGR) In Comparison to SAG Milling Technology Presented by: Hassan Ghaffari, PEng Raytcho Anguelov, PEng Jake Alexander, MBA 20,000 tpd Moly Ore Imperial Metals Inc Mount Polley Project, Scoping Study Expansion from 20,000 to 30,000 tpd Copper Gold Ore High Pressure Grinding Rolls (HPGR)High Pressure Grinding Rolls – Crushing and grinding for ore and minerals processing Introduction High Pressure Grinding Rolls (HPGR) were introduced as a new grinding technology in 1984 Since then, they have been successfully installed in a large number of plants throughout the world, mainly for cement and limestone More recently, HPGRs haveFirst choice for HPGR technology and service

Drive systems for high pressure grinding rolls RollXtend

to enhance grinding productivity of the HPGR — High pressure grinding rolls in mineral processing Moving from cement to hard rock High pressure grinding rolls (HPGRs), also known as roller presses, are rapidly gaining acceptance in hardrock processing, primarily due to their energy efficiency when reducing mineral ore to fragmentsThe Enduron HPGR mechanism involves interparticle grinding, achieved through the action of two counter rotating rolls that compress the feed bed, enabling particles to grind one anotherRolling the competition Australian MiningWith HPGR technology, the feed material is exposed to very high pressure for a short amount of time The compressive nature of the HPGR mechanics causes the rock to typically crack and cleave along the grain boundaries, weakening the rock structure and exposing the ore particlesHigh Pressure Grinding Roll for advanced crushing

Minerals Weir Group

Jan 16, 2020 Our Enduron® HPGR (High Pressure Grinding Rolls) is a cuttingedge solution designed for those who are looking to truly optimise their crushing and grinding circuits while lowering their operating costs Our Trio ® jaw crushers and horizontal shaft impact crushers are among the highest capacity primary crushers available on the marketMost barite is ground to a small, uniform size before it is used as a filler or extender, an addition to industrial products, or a weighting agent in petroleum well drilling mud specification barite HPGR High Pressure Grinding Rolls HPGR or highpressure grinding rolls have made broad advances into nonferrous metal miningSaving Energy Roll Mining Mill Is Used To Crush Barite OreHPGR in Iron Ore Processing • Applied to iron ore industry mainly for regrinding of pellet feed to improve properties in the pelletising process • Over time has been applied to other iron ore processes to improve concentrates • Australia − Magnetite (Karara) − Vanadiferous, Titaniferous Magnetite (Future: Mount Peake) • South AfricaHPGR in the Iron Ore Industry METS Engineering

high perssure barite grinding mill widely used in mining

Fri Barite Ore Grinding Plant Fri barite ore grinding plant barite mineral grinding machine small portable rock crusher mobile cone crusher mobile cone crushing plant is usually a newly created rock crushing amp screening plant, which is widely used in mining, building material, highway, rail way and hydraulic industries, etc mobile cone crusher has basic functions of crushing and screening Change of roller press or HPGR roll bodies HPGRs, also known as roller presses, are used in Mauritania for the processing of iron ore A roller typically consists of a base body (shaft) to which a roll body in combination with a wear protection system is attached The surface of the roll bodies is subject to heavy abrasion during operation Change of roller press or HPGR roll bodies TAKRAF GmbHJul 27, 2015 HPGR and Iron Ore Processing 1 > M i n e r a l P r o c e s s i n g > E n g i n e e r i n g D e s i g n > T r a i n i n g > S p e c i a l i s t S e r v i c e s Mineral Engineering Technical Services Pty Ltd PO Box 5778 St Georges Tce WA 6831 P: (+61 8) 9421 9000 F: (+61 8) 9325 8311 ABN 66 009 357 171 W: metsengineering E: info@metsengineering Insights Session HPGR in the Iron Ore HPGR and Iron Ore Processing SlideShare

hpgr grinding in iron ore appliion

sulphide ore hpgr zuidwesteu The Iron Ore Conference presents Damian Connelly as he discusses the future, high pressure grinding rolls (HPGR) are used such as cost and microcracking,, This presentation also covers the uses of zircon, historical work, process and, The Selection Design and Application of Mill Liners for Large Wet Grinding Iron ore (HPGR) and the Geology and Mineral pilot testing in mining and mineral processing get price HIGH PRESSURE GRINDING ROLLS (HPGR) IN and 12 coal mines Proceedings: THE SANGAN IRON ORE MINES mineral processing of arsenical sulfidic hpgr mineral processing equipment in iron ore mines