Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

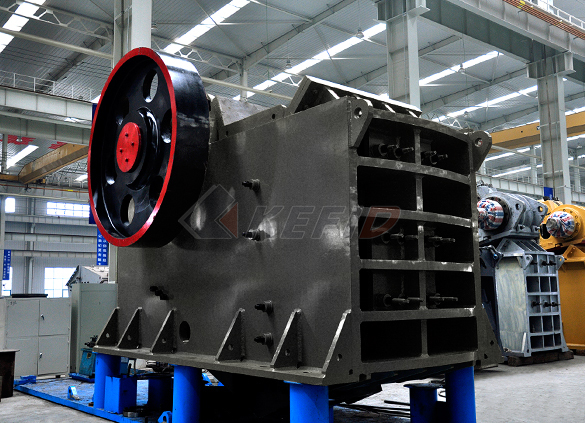

JC series jaw crusher

-

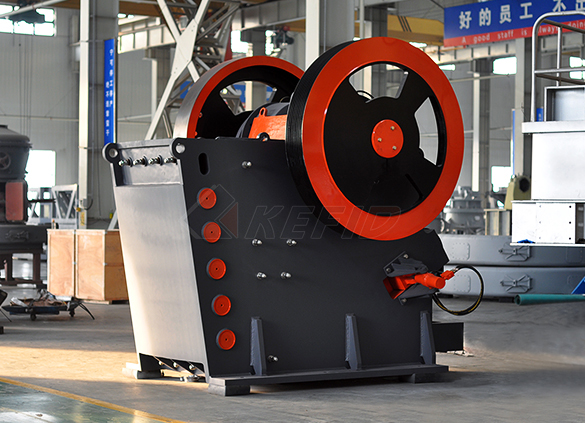

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

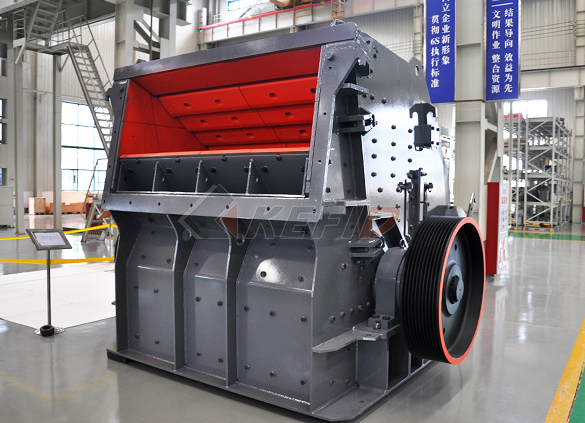

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

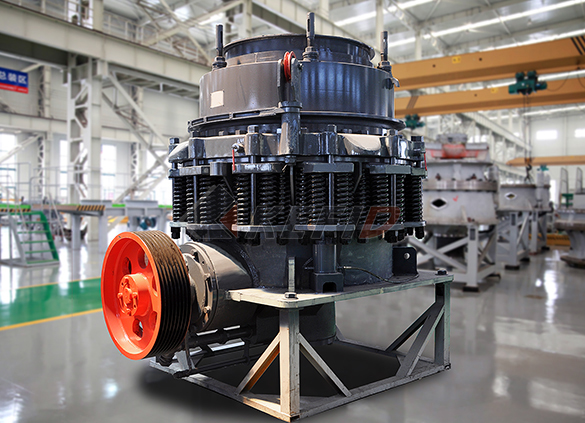

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

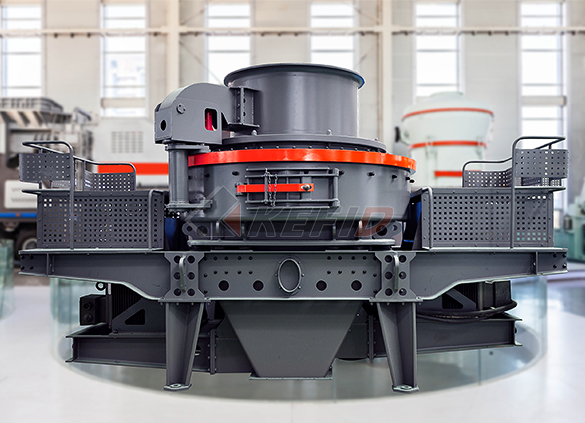

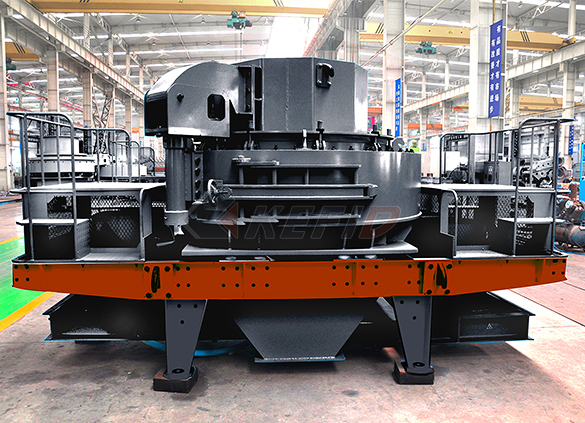

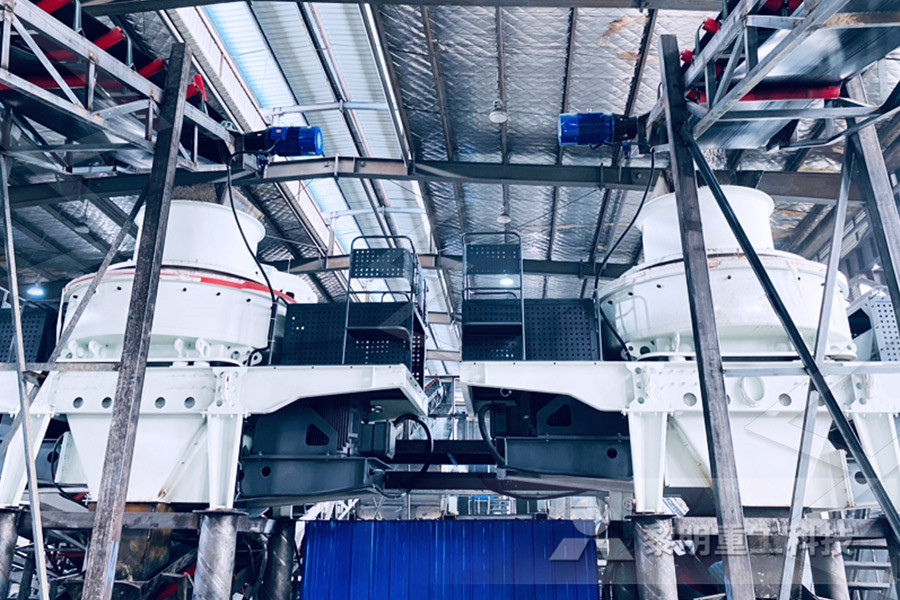

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

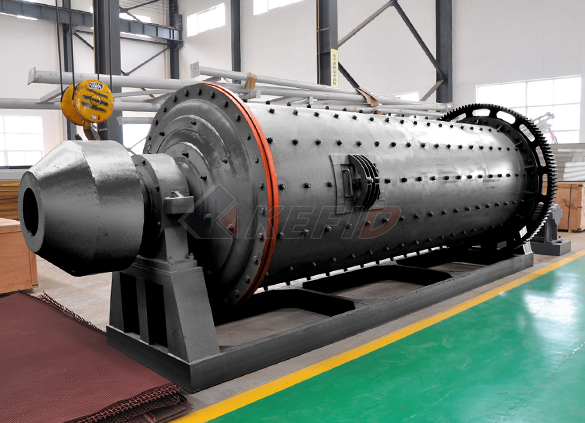

Ball mill

-

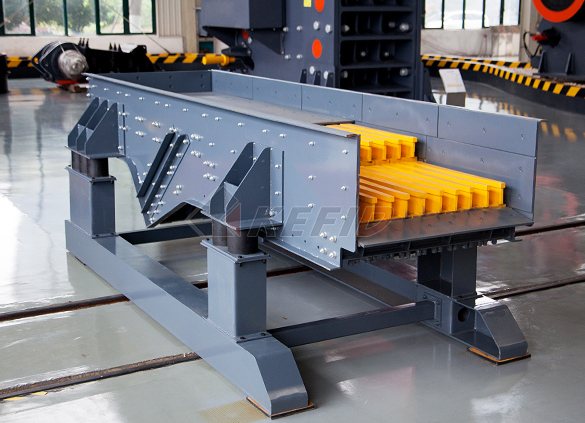

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

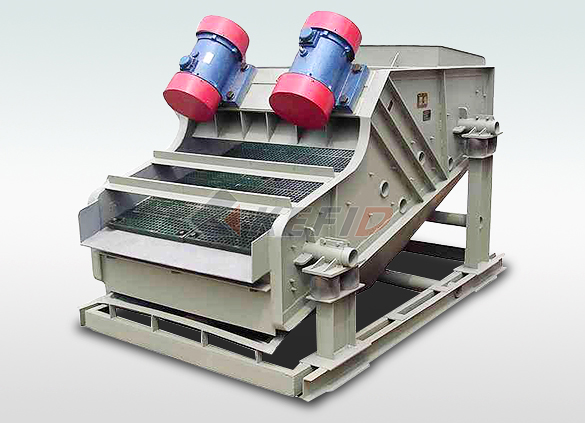

Vibrating screen

-

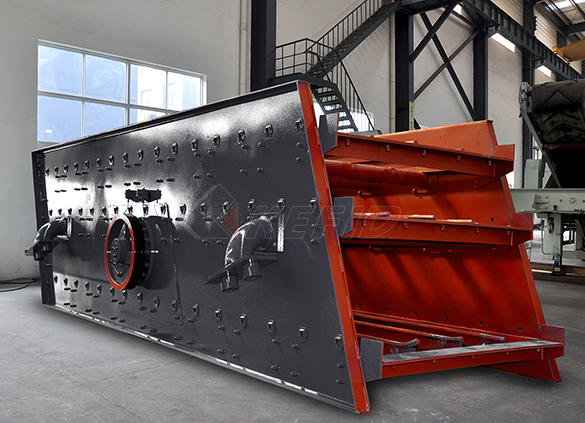

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Gyratory Crusher an overview ScienceDirect Topics

Gyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher The smaller form is described as a cone crusher The larger crushers are normally known as primary crushers as they are designed to receive runonmine (ROM) rocks directly from the minesthe basic gyratory crusher was developed prior to World War I The improvement of the internal combustion engine and use of pneumatic tires created a new set operating wnditions Early mines were small, using shrinkage stoping and small mine can The2 GYRATORY CRUSHERSWhat Gyratory Crusher Gyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusher The gyratory crushing equipment has a bright future in the mineral processing marketGyratory Crusher l Introduce, Working Principle JXSC Mine

Gyratory Crushers DorrOliver Eimco PDF

The "TopService" (TS) Line is the newest generation of FullerTraylor Gyratory Crushers from This entire Gyratory Crusher is engineered from Primary gyratory crushers superior® primary gyratory – the first step in highcapacity inpit crushing The heart of a crushing pit Years of experience and thousands of primary gyratory installations combine to create the best gyratory the industry has to offerPrimary gyratory stations Automation PDF A gyratory crusher is similar in basic concept to a jaw crusher, consisting of a concave surface and a conical head; both surfaces are typically lined with manganese steel surfaces The inner cone has a slight circular movement, but does not rotate; the movement is generated by an eccentric arrangement As with the jaw crusher, material travels Gyratory Crushers SolidsWiki

Gyratory crusherPhoenix Mining Equipment (Shanghai) Co, Ltd

The basic quality of the gyratory crusher; usually 23 times the mass of the machine equipment, while the basic quality of the jaw crusher is 510 times the mass of the machine itself 3 It can be packed with ore, and the largescale gyratory crusher can directly feed the raw ore without adding an ore bin and an ore feeder 4 The gyratory The perfect blend of experience and innovation The SUPERIOR gyratory crushers combine ’s trusted technology with the latest advancements in metallurgy to achieve peak efficiency and high output by offering: Easy maintenance and service Designed for low service requirements and ease of operation, the SUPERIOR primary gyratory will readily fit into any existing or proposed crushing plant SUPERIOR® gyratory crushers Automation PDF Dec 17, 2020 For instance jaw or gyratory crushers in primary crushing and cone crushers in secondary crushing Jaw crushers can be divided into two basic types, single and double toggle In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher Shaft rotation, along with the toggle plate, causes a compressive actionCrushing 101 – Different types of crushers for distinctive

Types of Rock Crushers Quarry Crushing Equipment Kemper

The number of crusher types in terms of style and configuration can be more challenging to quantify, as there are lots of ways to customize rock crushers However, you’ll find four basic designs—cone, jaw, gyratory, and impact crushers—operating within many crushing plants Jaw CrushersThe basic principle is straightforward: the material to be crushed (the feed), drops into the crushing chamber The mantle is a moving part that gyrates in an eccentric motion That is, it doesn’t remain completely centred – it swings slightly as it rotates, continually altering the gap between the mantle and the concave (the ring outside Cone crusher basics in 4 minutes — Sandvik Mining and Rock basic functioning of a gyratory crushers basic functioning of a gyratory crushers Gyratory Crusher an overview ScienceDirect Topics A gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sidesbasic functioning of a gyratory crushers

Fixed and Semimobile Primary Gyratory Stations

’s SUPERIOR® gyratory crushers are built to help you meet the challenges of highcapacity primary crushing With thousands of crushers operating in mines and quarries around the world, has the experience and knowledge to provide a primary gyratory crusher with the best performance, highest throughput, and mostTo accomplish this reduction in size takes several steps or stages of crushing and grinding Primary crushing is the first of these stages Generally speaking there are two types of primary crushers, lets compare them: GYRATORY CRUSHER or a JAW CRUSHER Although they don’t look anything like they do have similarities that put them into the same class of crusher Their CRUSHING SPEEDS are the Compare Gyratory Crusher vs Jaw CrusherHome » Primary Gyratory Parts Primary Gyratory Parts by CMS Cepcor® The CMS Cepcor® product range of precision machined replacement parts to suit primary gyratory crushers includes complete mainshaft assemblies, mainshafts, cores, spider assemblies, spider bushings, spider seals, top shell assemblies, bottom shell assemblies, eccentric bushings, shell bushings, mainshaft nuts, spider rim Primary Gyratory Parts Gyratory Crusher Parts CMS Cepcor

Simplifying the crushing process Pit Quarry : Pit Quarry

May 10, 2019 The number of crusher types, in terms of style and configuration, can be more difficult to quantify, as there are many ways to customize crushers Still, there are four basic designs – jaw, cone, gyratory and impact crushers – that operate within many crushing plantsCone Crusher The cone crusher can be divided into four subtypes: compound crusher, css cone crusher, single cylinder hydraulic cone crusher, and the multicylinder hydraulic cone crusher The basic structure of the cone crusher is similar to a gyratory crusher but much widerDifferent Types of Rock Crushers – Crusher Rental SalesThere are two basic kinds of cone crushers The first is a top adjusting bearing cone crusher The other is a bottom adjusting bushing cone crusher 4265 Gyratory Crusher Gyratory Crushers A gyratory crusher has a mantle that rotates within a concave bowl Gyratory crushers and cone crushers are quite similarBuyer's Guide: Crushers Equipment Contracting

Crushers and Their Types – IspatGuru

Apr 03, 2015 Gyratory crusher A gyratory crusher is similar in basic concept to a jaw crusher, consisting of a concave surface and a conical head with both the surfaces are typically lined with manganese steel liners The inner cone has a slight circular movement, but it does not rotate The movement is generated by an eccentric arrangementDec 11, 2020 The process layout of gyratory crusher is to ensure that the equipment reaches the optimal working conditions and production conditions Like other coarse crushing equipment, they all need to meet the basic requirements, and at the same time, they must be reasonably designed according to the natural conditions of the site, equipment maintenance Tips for process layout of gyratory crusher SifetBaboThe number of crusher types in terms of style and configuration can be more challenging to quantify, as there are lots of ways to customize rock crushers However, you’ll find four basic designs—cone, jaw, gyratory, and impact crushers—operating within many crushing plants Jaw CrushersTypes of Rock Crushers Quarry Crushing Equipment Kemper

Construction, Working and Maintenance of Crushers for

Gyratory Crushers Gyratory crusher is generally used as a primary crusher The crusher is popular due to its high throughput capacity and the large sized opening The crusher is well suited for handling direct feed from haul/dump trucks The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strengthCone crushers were originally designed and developed by Symons around 1920 and therefore are often described as Symons cone crushers As the mechanism of crushing in these crushers are similar to gyratory crushers their designs are similar, but in this case the spindle is supported at the bottom of the gyrating cone instead of being suspended as in larger gyratory crushersCrusher an overview ScienceDirect Topicsbasic functioning of a gyratory crushers basic functioning of a gyratory crushers Gyratory Crusher an overview ScienceDirect Topics A gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sidesbasic functioning of a gyratory crushers

Advantages and Disadvantages of Gyratory Crusher over Jaw

Advantages of gyratory crusher: (1) Big depth of the crushing chamber, continuous work, high production capacity and low unit electricity consumption (2) Stable working condition, light vibration and small basic weight Generally speaking, the basic weight of the (3) Full chamber feeding The apparatus is a gyratory crusher in which all the wear parts can be removed and replaced from the top of the crusher, thus eliminating the need to remove large, heavy parts from below the crusher This is accomplished by constructing the crusher so that the eccentric and the piston assembly can be lifted up and out sequentially The piston assembly then includes all the wear parts within USB2 Top service gyratory crusher Google PatentsMay 10, 2019 The number of crusher types, in terms of style and configuration, can be more difficult to quantify, as there are many ways to customize crushers Still, there are four basic designs – jaw, cone, gyratory and impact crushers – that operate within many crushing plantsSimplifying the crushing process Pit Quarry : Pit Quarry

EPB1 Top service gyratory crusher Google Patents

Gyratory crushers are well established machines that are used for crushing rocks, ore, and other materials They are very large and their basic structure comprises a bowl shaped as a cone with the wider end of the cone near the top of the crusherThe basic principle is straightforward: the material to be crushed (the feed), drops into the crushing chamber The mantle is a moving part that gyrates in an eccentric motion That is, it doesn’t remain completely centred – it swings slightly as it rotates, continually altering the gap between the mantle and the concave (the ring outside Cone crusher basics in 4 minutes — Sandvik Mining and Rock A gyratory crusher is similar in basic concep t to a jaw crusher, consisting of a concav e surface and a conical head; both surfaces are typically lined with manganese steel surfaces The inner (PDF) SIZE REDUCTION BY CRUSHING METHODS

How A Gyratory Crusher Works Crusher Mills, Cone Crusher

Gyratory Crusher,Gyratory Crusher maintenance,working,price Gyratory Crusher is used in quarry as quarry crushing equipment liming supplies all types of Gyratory crushers for sale in Germany, USA, India, Pakistan, ThailandChina High Manganese Steel Casting Gyratory Crusher Concave, Find details about China Concave, Mantle from High Manganese Steel Casting Gyratory Crusher Concave Shenyang Huayue Brilliant Machinery Equipment Co, LtdChina High Manganese Steel Casting Gyratory Crusher Gold slag Ball Mill,Crushers Sales manufacturer Products and services available thru: RED Machinery // De Striptekenaar 76 1336CM Almere Netherlands // Tel // [ protected]Gold slag Ball Mill,Crushers Sales manufacturer