Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

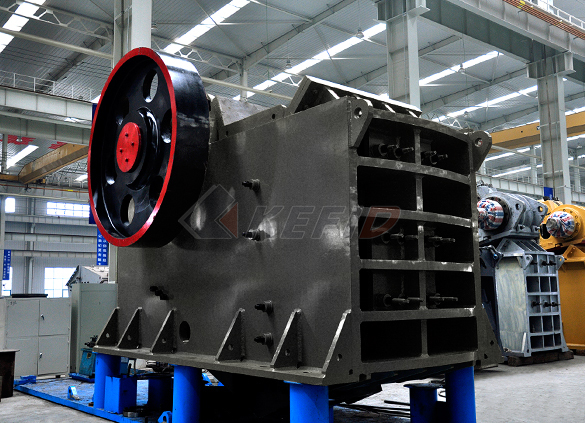

JC series jaw crusher

-

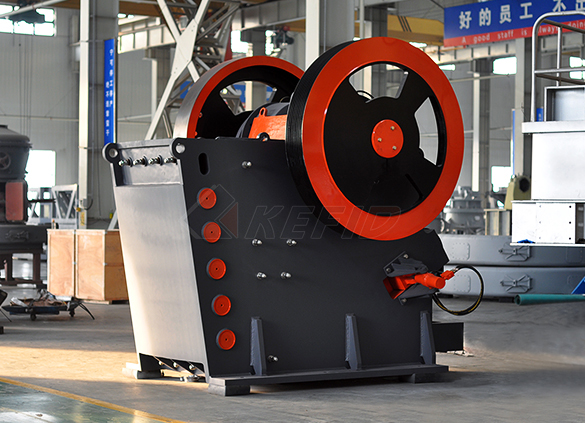

Jaw crusher

-

HJ series jaw crusher

-

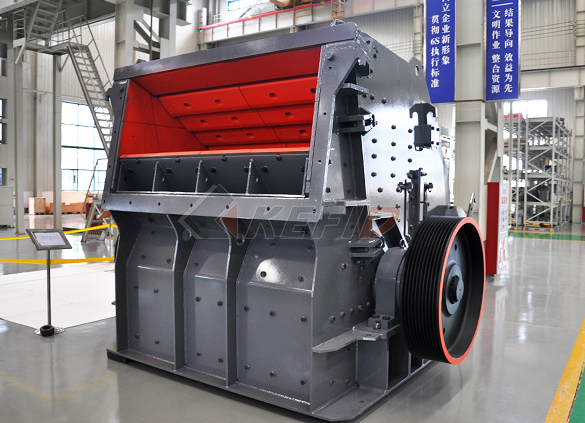

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

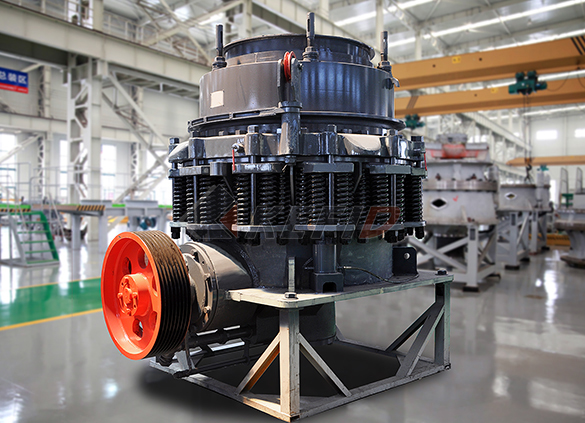

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

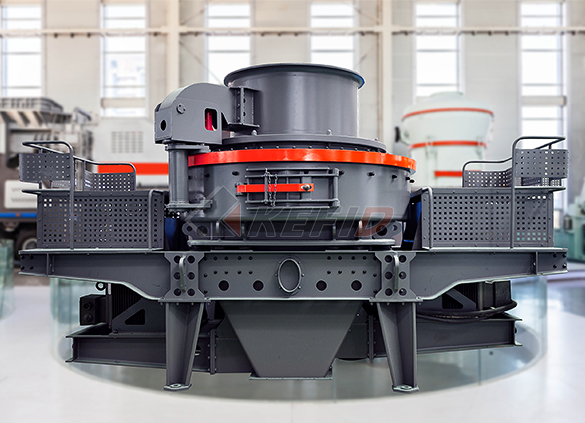

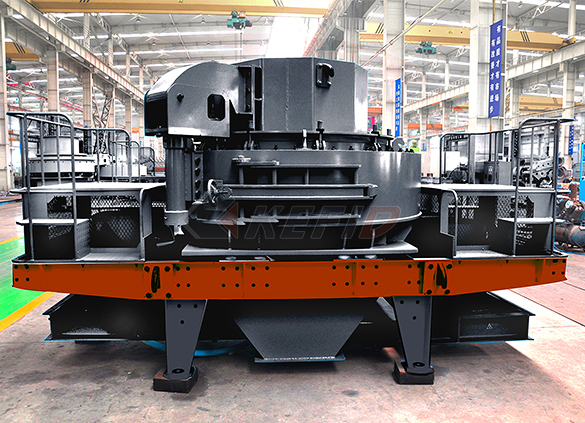

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

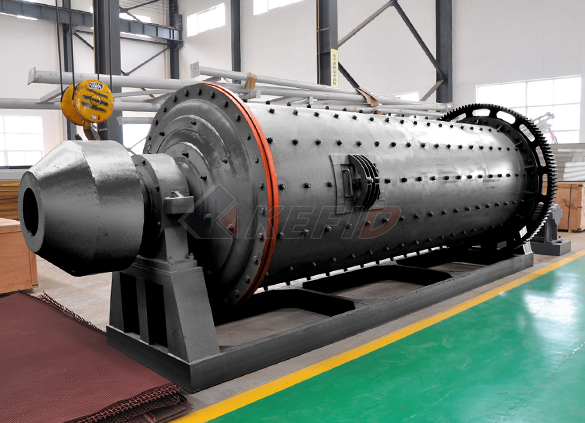

Ball mill

-

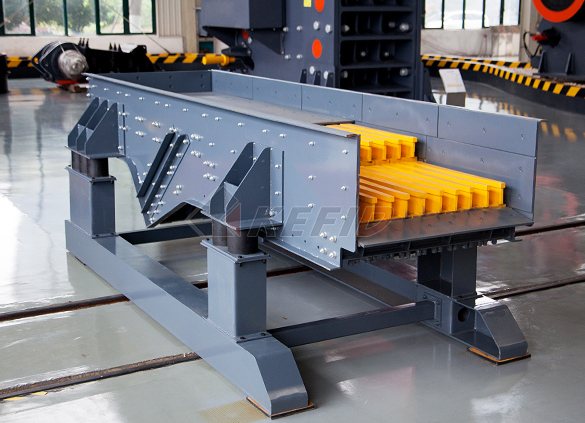

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

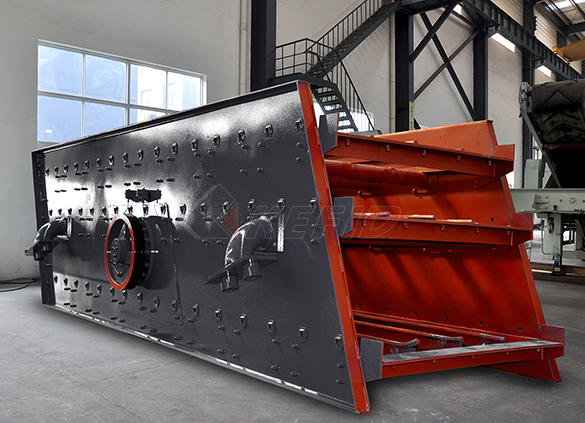

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

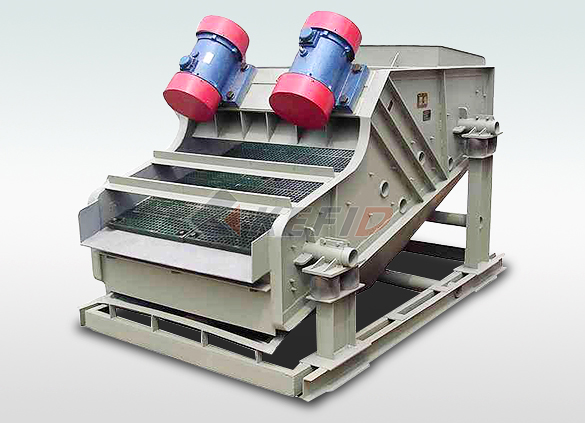

High frequency screen

ball mill Encyclopedia

ball mill A vessel in which material is ground by rolling with heavy balls, used especially for hard materials Source for information on ball mill: A Dictionary of Food and Nutrition dictionaryball mill: n porcelain jar containing rollers spun on larger rollers, used to grind substances, such as homeopathic remedies, to a fine powderBall mill definition of ball mill by The Free DictionaryThe ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc as well as for ore dressing of both ferrous nonferrous metalsBALL MILL : definition of BALL MILL and synonyms of BALL

Ball Mills an overview ScienceDirect Topics

3611 Ball Milling A ball mill is a type of grinder used to grind and blend bulk material into QDs /nanosize using different sized balls The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shellBall mill definition is a pulverizing machine consisting of a rotating drum which contains pebbles or metal balls as the grinding implementsBall Mill Definition of Ball Mill by MerriamWebsterBall mill definition, a grinding mill in which the material to be ground is tumbled in a drum with heavy balls of iron, steel, or stone See moreBall mill Definition of Ball mill at Dictionary

BALL MILL : definition of BALL MILL and synonyms of BALL

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc as well as for ore dressing of both ferrous nonferrous metals(1) Types on the Basis of Cylinder 1 Short Cylinder Ball Mill: The ball mill with the cylinder length (L) less than 2 times of the cylinder diameter, ie the ball mill with L ≤ 2D is short cylinder ball mill, which is usually of single bin structure, mainly used for rough grinding or primary grinding operation, and can realize the wide use of 23 ball mills in seriesWhat is Ball Mill How Many Types of Ball Mills MCOleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Ball Mills an overview ScienceDirect Topics

Ball Mill vs Rod Mill How To Choose Ball Mill or Rod

The overall design of ball mills and rod mills are compact, with simple operation and easy maintenance But the both are different in performance and applications In this article, the similarities and differences between ball mills and rod mills are analyzed from 9 aspects, and suggest how to choose ball mill or rod millBall mills scale up well and in fact improve in performed with increasing size Ball mills are available in sizes from laboratory scale (also called milling jars) of 01 usg to large 5,000 gallon mills Ball mills are available in various contact materials to accommodate contamination and wear requirementsBall Mill Application and Design Paul O AbbeBALL MILL Definition Of BALL MILL And Synonyms Of BALL The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc as well as for ore dressing of both ferrous nonferrous metalsball mill define ball mill at dictionary

what is the difference between vertical mill ball mill

Mar 23, 2013 Ball mill – Wikipedia, the free encyclopedia A ball mill is a type of grinder used to chemicals, ceramic raw materials Cement grinding Vertical roller mills versus ball mills The grinding process in ball mills and vertical roller Ball Swing A ball swing is when the ball gets passed or moved from one side of the floor to the other This is also called a reversal This is also called a reversal Baseline Drift a baseline drift is a pass made by a player attacking on the baseline and then passing * Ball (Basketball) Definition Online EncyclopediaFeb 01, 1993 6 Conclusion The ball mill is both a violent and a closed operating environment where the effects of ball mill parameters P Radziszewski, S Tarasiewicz 1 Ball mill wear 315 S LU '80 'sub 00 j\ 0 20 25 35 10 MILL FILLIN6 [) Fig 16 Wear rate as a function of ball mill filling TABLE 5Modelling and simulation of ball mill wear ScienceDirect

Mill (grinding) Wikipedia

A VSI mill throws rock or ore particles against a wear plate by slinging them from a spinning center that rotates on a vertical shaft This type of mill uses the same principle as a VSI crusher Tower mill Tower mills, often called vertical mills, stirred mills or regrind mills, are a more efficient means of grinding material at smaller particle sizes, and can be used after ball mills in a The final plan was to increase the ball charge in the SAG and ball mill to 10% v / v and 27% v / v, respectively; set the upper limit of the operating power in the ball mill to 5800 kW; use a TC Series crusher (without a power/feed rate–controlling device, but with a feed bin) to crush pebbles for recirculation back to the SAG mill feed Minerals Free FullText Optimizing Performance of SABC Apr 10, 2015 Ball mill Wikipedia, the free encyclopedia A ball mill is a type of grinder used to grind materials into extremely fine The ball mill is a key piece of equipment for grinding crushed materials, and it is widely 〕jaw and cone crusher in kenya】》Quarry Machinery Application: ore crushing and mining beneficiation ernest fleming machinery ball mill SlideShare

Ball Mill: Operating principles, components, Uses

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Ball Mills an overview ScienceDirect TopicsBall mill A typical type of fine grinder is the ball millA slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grinds material to the necessary fineness by friction and impact with the tumbling balls Ball mills normally operate with an approximate ball charge of 30%Mill (grinding) : definition of Mill (grinding) and

Ball Mill vs Rod Mill How To Choose Ball Mill or Rod

The overall design of ball mills and rod mills are compact, with simple operation and easy maintenance But the both are different in performance and applications In this article, the similarities and differences between ball mills and rod mills are analyzed from 9 aspects, and suggest how to choose ball mill or rod millhighenergy mills This former definition is not also adapted because the use of dry processing conflicts with examples of moist process of some materials [2] A wider definition was proposed by Schwarz [3], for whom mechanical alloying is a highenergy ball mill technique employed to prepare powder alloys with unequal microstructure On theHighEnergy Ball Mill Processing IPENApr 10, 2015 Ball mill Wikipedia, the free encyclopedia A ball mill is a type of grinder used to grind materials into extremely fine The ball mill is a key piece of equipment for grinding crushed materials, and it is widely 〕jaw and cone crusher in kenya】》Quarry Machinery Application: ore crushing and mining beneficiation ernest fleming machinery ball mill SlideShare

Modelling and simulation of ball mill wear ScienceDirect

Feb 01, 1993 6 Conclusion The ball mill is both a violent and a closed operating environment where the effects of ball mill parameters P Radziszewski, S Tarasiewicz 1 Ball mill wear 315 S LU '80 'sub 00 j\ 0 20 25 35 10 MILL FILLIN6 [) Fig 16 Wear rate as a function of ball mill filling TABLE 5Optimization of mill performance by using online ball and pulp measurements by B Clermont* and B de Haas* Synopsis Ball mills are usually the largest consumers of energy within a mineral concentrator Comminution is responsible for 50% of the total mineral processing cost In today’s global markets, expanding mining groups are tryingOptimization of mill performance by usingThe final plan was to increase the ball charge in the SAG and ball mill to 10% v / v and 27% v / v, respectively; set the upper limit of the operating power in the ball mill to 5800 kW; use a TC Series crusher (without a power/feed rate–controlling device, but with a feed bin) to crush pebbles for recirculation back to the SAG mill feed Minerals Free FullText Optimizing Performance of SABC

* Ball (Basketball) Definition Online Encyclopedia

Ball Swing A ball swing is when the ball gets passed or moved from one side of the floor to the other This is also called a reversal This is also called a reversal Baseline Drift a baseline drift is a pass made by a player attacking on the baseline and then passing Jul 13, 2013 Ball Mill In Uae,Ball Mill For Sale,Export Ball Millliming Ball mill is an efficient tool for fine powder grinding Ball Mill is used to grind many kinds of material of a ball mill worldcrushersApr 11, 2017 In the previous article we considered the method for determining the bulk weigh of new grinding media Determination the grinding balls bulk weigh directly operating in a ball mill becomes necessary on practice It is done in order to accurately definition the grinding ball mass during measuring in a ball mill and exclude the mill overloading with grinding balls possibilityThe grinding balls bulk weight in fully unloaded mill

Mill Speed Critical Speed Paul O Abbe

Mill Speed No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar rolling mill, its rotational speed is important to proper and efficient mill operation Too low a speed and little energy is imparted on the productBall Mills The term “ball mill’ is generally used to refer to a cylindrical mill whose length is less than, equal to, but not much greater than its diameter It was initially developed for relatively coarse grinding, but by using it in closed circuit with a classifier its use has been extended for fine grindingLaboratory Grinding Mill 911Metallurgist