Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

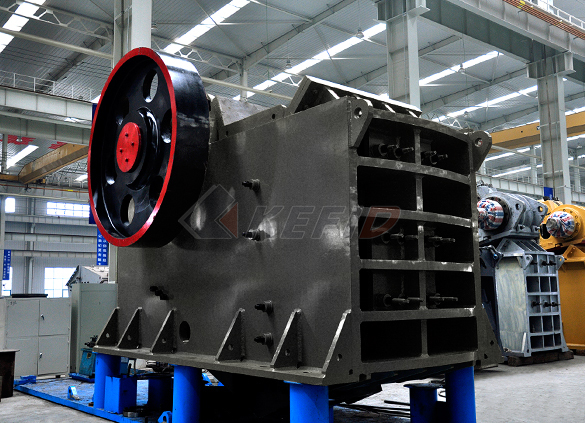

C6X series jaw crusher

-

JC series jaw crusher

-

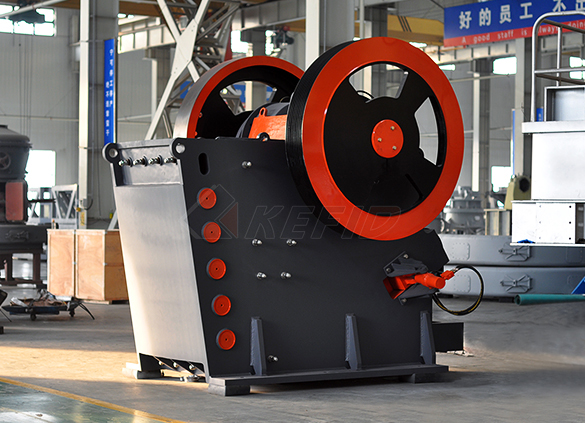

Jaw crusher

-

HJ series jaw crusher

-

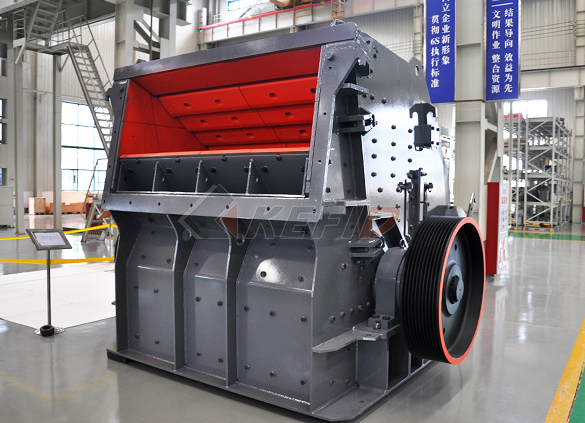

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

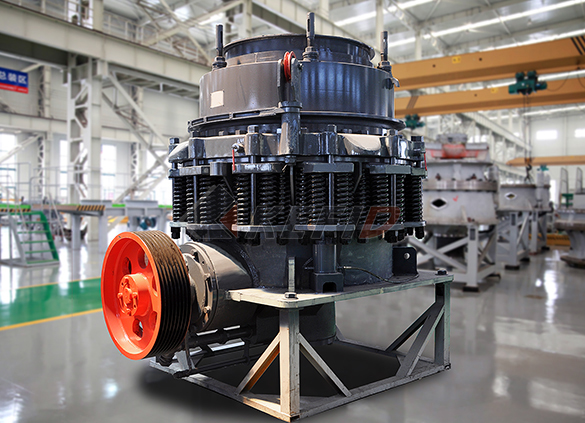

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

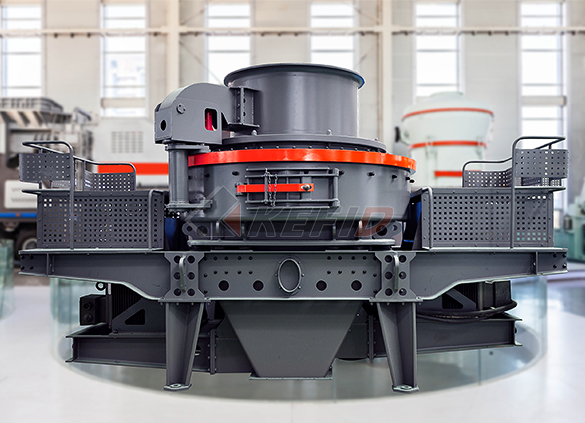

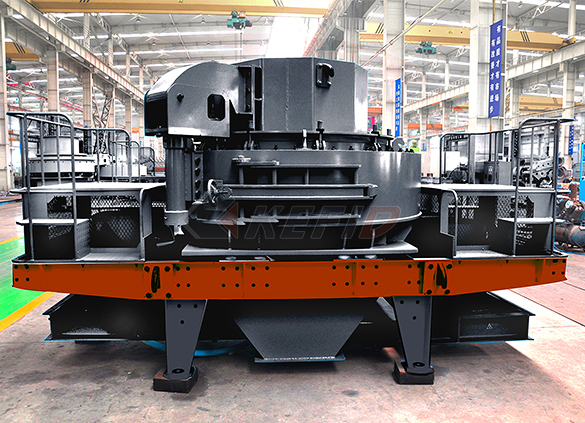

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

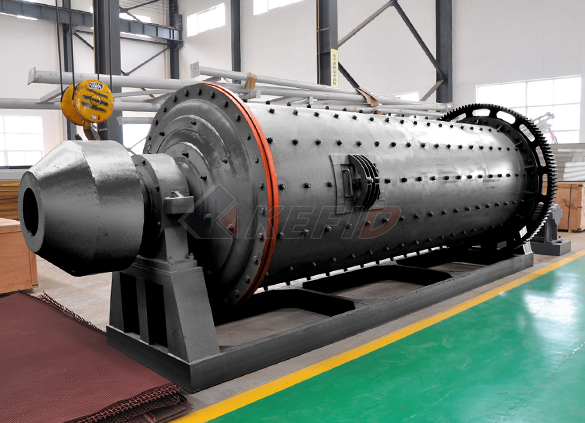

Ball mill

-

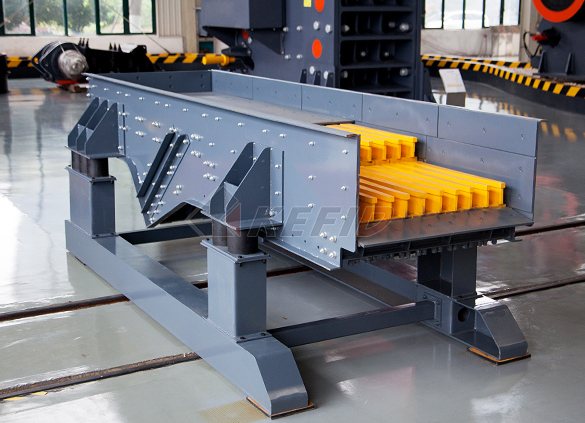

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

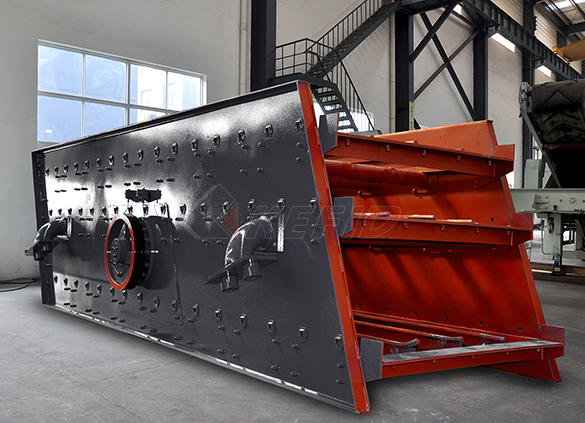

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

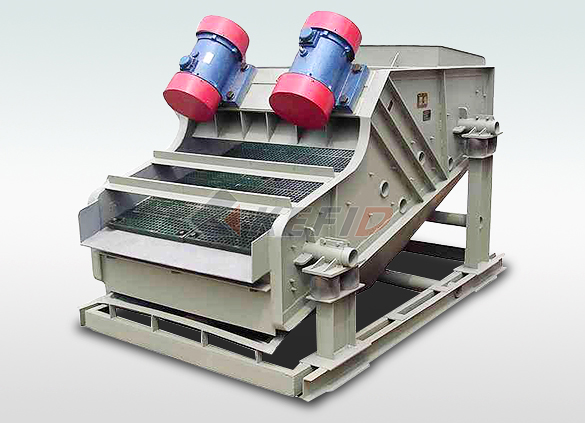

High frequency screen

COMPRESSIVE STRENGTH OF CONCRETE USING LATERITIC

cubes) were made using varying contents of laterite and quarry dust as fine aggregate The quantity of laterite was varied from 0% to 100% against quarry dust at intervals of 25%Jan 01, 2012 Samples of concrete (eg cubes) were made using varying contents of laterite and quarry dust as fine aggregate The quantity of laterite was varied from 0% Compressive strength of concrete using lateritic sand and The suitability of quarry dust as alternative material for the river sand in concrete manufacturing is studied M25 grade concrete was prepared with 0%, 20%, 40%, 60%, 80% partial replacement of Study on Performance of Quarry Dust as Fine Aggregate in

The use of red earth, lateritic soils and quarry dust as

Mar 01, 2020 River sand and lateritic soils were sourced locally around the Landmark University premise with a geographical position of 81239° N, 50834° E Red earth soil was gotten at a location around a hilly terrain within the University premise while quarry dust was obtained from a quarry site within the township of Omuaran at a location of 81402° N, 50963° E Ordinary Portland cement that The reduction in the sources of natural sand and the requirement for reduction in the cost of concrete production has resulted in the increased need to identify substitute material to sand as fine aggregates in the production of concretes Quarry dust, a byproduct from the crushing process during quarrying activities is one of such materials EXPERIMENTAL STUDY ON REPLACEMENT OF FINE The reduction in the sources of natural sand and the requirement for reduction in the cost of concrete production has resulted in the increased need to identify substitute material to sand as fine(PDF) EXPERIMENTAL STUDY ON REPLACEMENT OF FINE

Analysis of Concrete Made from Quarry Dust

environmental waste within the form of fine material (quarry dust powder) this is especially a concern for the aggregate the mixture process for factorymade fine aggregate to be used in Portland cement concrete because of standards and performance requirements A Benefits of using Quarry DustThe Quarry dust may be used in the place of river sand fully or partlyA comparatively good strength is expected when sand is replaced partially or fully with or without concrete admixturesIt is proposed to study the possibility of replacing sand with locally available crusher waste without sacrificing the strength and workability of concrete(PDF) Use of Quarry Dust to Replace Sand in Concrete – An This paper is part of a study investigating the structural characteristics of concrete using various combinations of lateritic sand and quarry dust as complete replacement for conventional river sand fine aggregate Samples of concrete (eg cubes) were made using varying contents of laterite and quarry dust as fine aggregate The quantity of laterite was varied from 0% to 100% against quarry COMPRESSIVE STRENGTH OF CONCRETE USING LATERITIC SAND AND

Partial Replacement of Sand by Quarry Dust in Concrete

As the percentage of Quarry Dust gradually increases, UNIVERSITY, INDIA) the Compressive strength of concrete will also increase [2] FLEXURAL AND TENSILE STRENGTH PROPERTIES OF with condition that percentage of Quarry Dust should CONCRETE USING LATERITIC SAND AND QUARRY DUST AS FINE AGGREGATE not exceed 50%Hence, concrete proportion of lateritic sand and quarry dust can be used for construction provided the mixture of lateritic sand content is reserved below 50% Both flexural strength and tensile strength are increased with increase in lateritic contentAccording to Soutsos et al [8], the physical characteristics of recycled destruction (PDF) An Experimental study on Effects of Quarry Dust as 10:90 1769 2088 2034 2932 Concrete containing quarry dust as fine aggregate can be effectively utilized in the construction industry with good 00:100 1584 2043 1966 2032 quality materials, appropriate dosage of super plasticizer, appropriate mixing methods, and proper curing thereby 5(PDF) An Experimental study on uses of Quarry Dust to

Partial Replacement of Sand with Quarry Dust in Concrete

The reduction in the sources of natural sand and the requirement for reduction in the cost of concrete production has resulted in the increased need to identify substitute material to sand as fine aggregates in the production of concretes especially in Concrete Quarry dust, a byproduct from the crushing process during quarrying activities is one of such materialsSep 01, 2015 The quarry sand is the coarse fraction of the quarry powder and is being used as the fine aggregate in place of river sand in concrete production The fine quarry dust fraction is commercially unused material Therefore, utilization of waste material quarry dust in the production of artificial aggregates is examined in this studyProperties of cold bonded quarry dust coarse aggregates Quarry Process Quarry process, also known as QP, dense grade aggregate (DGA), crusher run and road stone, is a combination of small, 3/4inchorless crushed stone and stone dust Most often it is made out of crushed limestone, granitegneiss, trap rock or a combination of the aforementionedCrushed Stone vs Quarry Process vs Stone Dust

Powerpoint Presentation On Soil Stabilization By Replacing

compressive strength of concrete using lateritic ARPN Journals lateritic sand and quarry dust as complete replacement for conventional river sand fine concrete in which the fine aggregates are lateritic soils sand aggregate for concrete works as presented in Figure 2 stabilized lateritic soils Read moreThis study compared the physical and mechanical properties of river sand concrete with quarry dust concrete The constituent materials were batched by weight The watercement ratio and mix ratio selected for the experimental investigation were 055 and 1:2:4, respectively The specimens were cured for 7, 14, 21 and 28 parison of physical and mechanical properties of river Use of Quarry Dust to Replace Sand in Concrete – An strength of concrete when replacing sand by quarry dust from 0% to in steps of 10% are forced to think of alternative materials The Quarry dust may be used in the aggregate and quarry dust as alternetive to sand in block production pdf

COMPRESSIVE STRENGTH AND WORKABILITY OF LATERIZED

combinations of lateritic sand and quarry sand as complete replacement for conventional river sand fine aggregate Quantity of lateritic sand varied from 0 to 50% against quarry dust at interval of 10% Concrete cubes were prepared for two mix ratios: 1:15:3 and 1:2:4 and three water/cement ratios: 05, 06 and 07 and were cured and tested in Use of Quarry Dust to Replace Sand in Concrete – An strength of concrete when replacing sand by quarry dust from 0% to in steps of 10% aggregate How To Use Quarry Dust In Concrete Blocks[6] Farid Debieb, Said Kenai, “The use of coarse and fine crushed bricks as aggregate in concrete” Construction and building materials, 2008, Pg No 886 to 893 [7] Joseph O Ukpata, Maurice E Ephraim, Godwin A Akeke, “Compressive strength of concrete using lateritic sand and quarry dust as fine aggregate”Effect of use of Silica Sand as Fine Material in Concrete

Replacement Of Coarse Aggregate In Concrete [Civil Planets]

Quarry dust For Partial Replacement The bricks, tile other lightweight materials are made from the quarry dust The chemical composition of quarry dust is mostly the same as granite rock So the strength and durability of quarry dust are good to use in concreteHence, concrete proportion of lateritic sand and quarry dust can be used for construction provided the mixture of lateritic sand content is reserved below 50% Both flexural strength and tensile strength are increased with increase in lateritic contentAccording to Soutsos et al [8], the physical characteristics of recycled destruction (PDF) An Experimental study on Effects of Quarry Dust as 10:90 1769 2088 2034 2932 Concrete containing quarry dust as fine aggregate can be effectively utilized in the construction industry with good 00:100 1584 2043 1966 2032 quality materials, appropriate dosage of super plasticizer, appropriate mixing methods, and proper curing thereby 5(PDF) An Experimental study on uses of Quarry Dust to

Partial Replacement of Sand with Quarry Dust in Concrete

The reduction in the sources of natural sand and the requirement for reduction in the cost of concrete production has resulted in the increased need to identify substitute material to sand as fine aggregates in the production of concretes especially in Concrete Quarry dust, a byproduct from the crushing process during quarrying activities is one of such materialseffect of quarry dust as partial replacement of sand in concrete dust as the fine aggregate decreases the cost of concrete production in terms of the quarry dust to be used as partial replacement material for sand in concrete 2 In the present study an ordinary Partial Replacement Of Sand By Graded Quarry Dust In [6] Farid Debieb, Said Kenai, “The use of coarse and fine crushed bricks as aggregate in concrete” Construction and building materials, 2008, Pg No 886 to 893 [7] Joseph O Ukpata, Maurice E Ephraim, Godwin A Akeke, “Compressive strength of concrete using lateritic sand and quarry dust as fine aggregate”Effect of use of Silica Sand as Fine Material in Concrete

Properties of cold bonded quarry dust coarse aggregates

Sep 01, 2015 The quarry sand is the coarse fraction of the quarry powder and is being used as the fine aggregate in place of river sand in concrete production The fine quarry dust fraction is commercially unused material Therefore, utilization of waste material quarry dust in the production of artificial aggregates is examined in this studybehaviour of concrete on the use of quarry dust to replace sand strength of concrete when replacing sand by quarry dust from 0% to in control concrete Keywords Concrete, quarry dust, river sand, compressive Read moreReplacement Of Sand By Quarry Dust In ConcreteQuarry Process Quarry process, also known as QP, dense grade aggregate (DGA), crusher run and road stone, is a combination of small, 3/4inchorless crushed stone and stone dust Most often it is made out of crushed limestone, granitegneiss, trap rock or a combination of the aforementionedCrushed Stone vs Quarry Process vs Stone Dust

Replacement Of Coarse Aggregate In Concrete [Civil Planets]

Quarry dust For Partial Replacement The bricks, tile other lightweight materials are made from the quarry dust The chemical composition of quarry dust is mostly the same as granite rock So the strength and durability of quarry dust are good to use in concreteEffect of Fly Ash on Mortar Mixes with Quarry Dust as Fine Aggregate Usage of quarry dust as partial replacement to river sand/natural sand further modified by partial replacement of pozzolanic materials like fly ash is receiving more attention these days as their use generally improves the properties of cement/concretePpt On Partial Replacement Of Sand With Quarry DustThe effect of the using waste marble dust as fine sand on the In this experimental study, the effects of using waste marble dust (WMD) as a fine material on the Key words: Waste marble dust, very fine sand, concrete, dynamic modulus of containing quarry rock dust and marble sludge powder as finedisadvantages of quarry dust uses in concrete

Studies on Pumice Lightweight Aggregate Concrete with

The lightweight aggregate is an aggregate that weighs less than the usual rock aggregate and the quarry dust is a rock particle used in the concrete for the experimentation The significant intention of the proposed technique is to frame a mathematical modeling with the aid of the optimization techniques The mathematical modeling is done by minimizing the cost and time consumed in the case of Compressive Strength of Concrete by Using Lateritic Sand and Quarry Dust CEX042 Use of Industrial Waste Red Mud in the Production of Self Compacting Concrete Sued as Fine Aggregate in Cement Concrete CEX056 Experimental Study on Strength of High Performance Concrete using Supplementry Cementing Material and Glass Fiber CEX057 CIVIL EXPERIMENTAL PROJECTS Majestic ProjectJun 12, 2013 Compressive strength of concrete using lateritic – ARPN Journals Samples of concrete (eg cubes) were made using varying contents of laterite and quarry dust as fine aggregate The quantity of laterite was varied from 0% to »More detailedlaterite stone as aggregate on concrete « Mining