Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

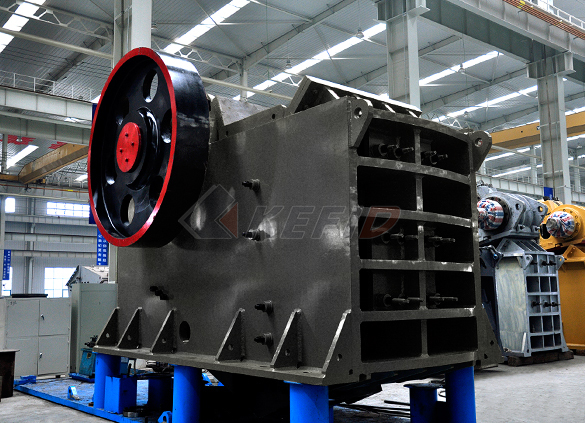

JC series jaw crusher

-

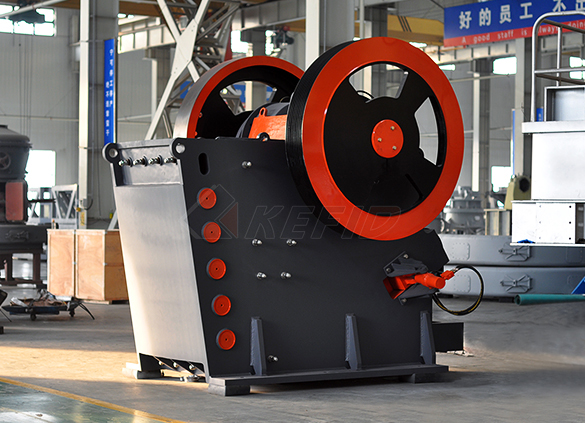

Jaw crusher

-

HJ series jaw crusher

-

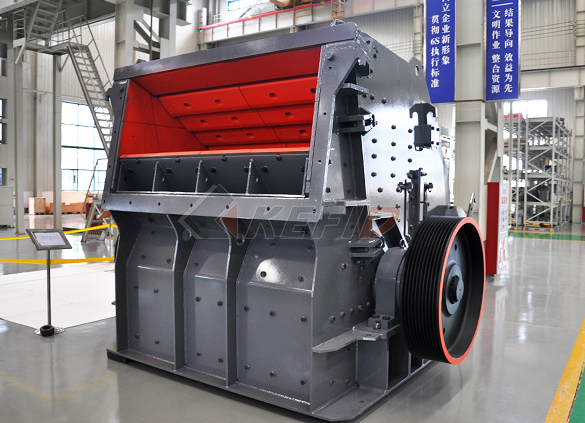

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

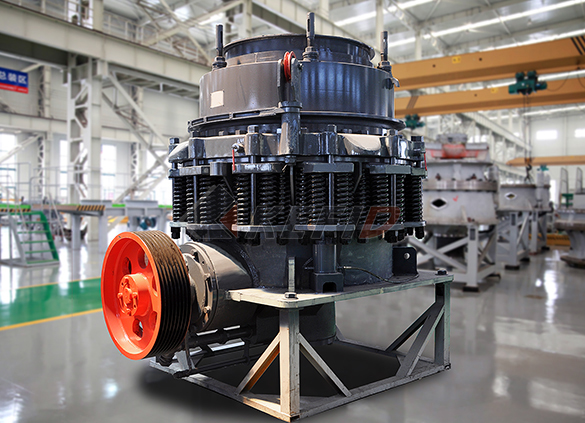

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

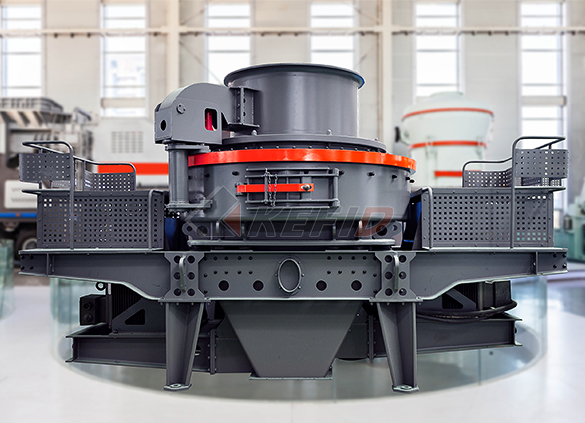

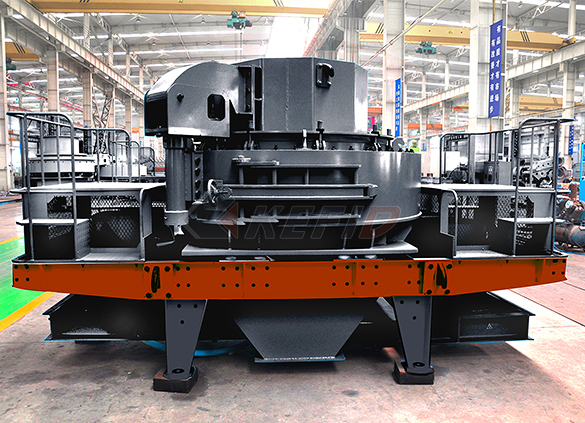

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

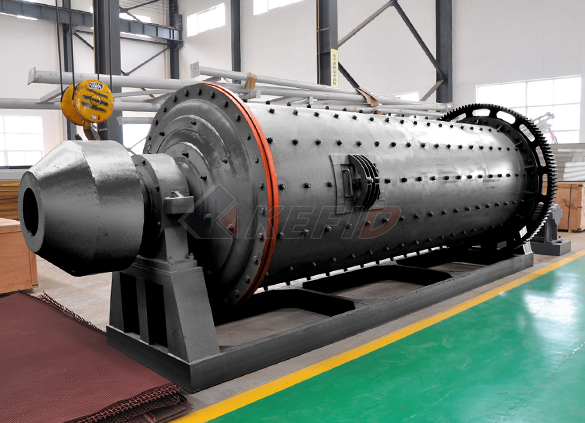

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

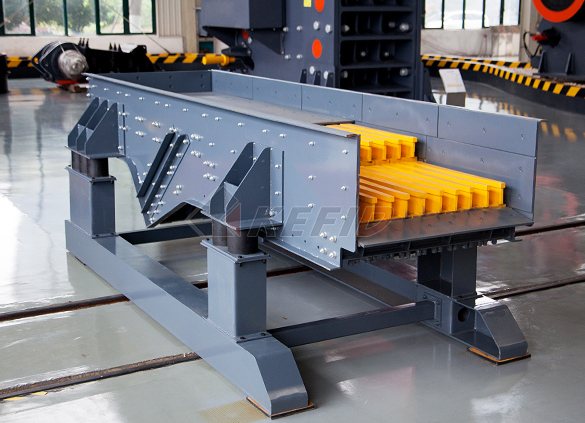

TSW series vibrating feeder

-

Vibrating feeder

-

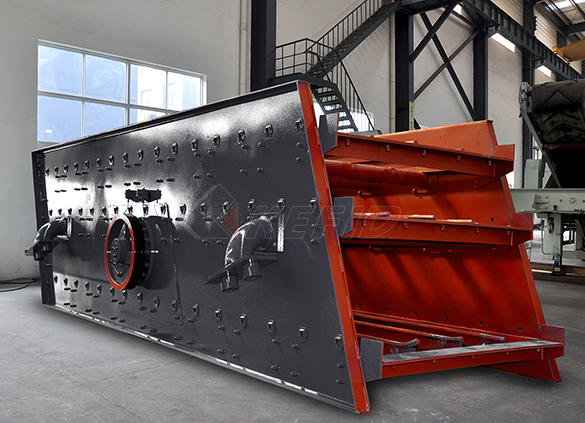

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

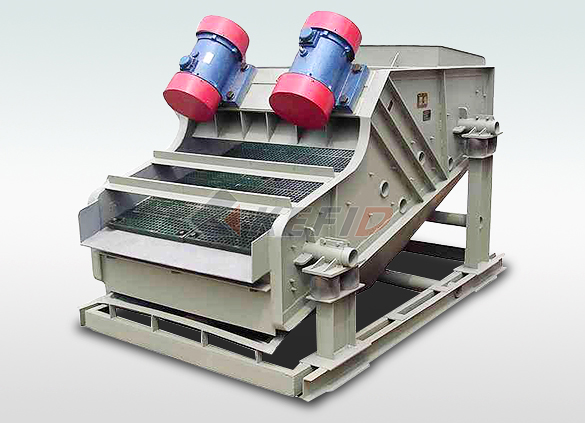

Electromagnetic vibrating feeder

-

High frequency screen

capacity of sag mills in mineral ore processing

Sino Grinding Mineral Processing Mineral processing typically involves the crushing and grinding of hard rock ore Crushed ore is introduced to semiautogenous grinding (SAG) mills, also known as primary mills, where grinding media is released like hammers to assist in the ore cracking / grinding process20’ EGL SAG mill, a Raptor 900 pebble crusher and two 24’ x 39’6” ball mills Each mill is equipped with a 2 x 8500HP dual pinion drive system The plant was designed to process 1585 h mtpof SAG feed From startup, the mill struggled to meet the required production rates Over time, a major initiative that involvedINCREASING SAG MILL CAPACITY AT THE COPPER SAG mill ArchivesInternational Mining SAG mills are a key asset for mineral processing operations as one of the critical stages of extracting mineral out of ore and their continued stable operation is central to productivity the JKMRC says However the performance Service Online; Processing Copper Ore In Sag MillsMINING solutioncapacity of sag mills in mineral ore processing

Gearless Mill Drives

Antamina Compania Minera Antamina SA Peru Project: One SAG Mill and 3 Ball Mill Drive Systems Capacity: SAG Mill 1000 t/h Ball Mills 1000 t/h Consultant: Bechtel, USA Mill Builder: FFE Minerals, USA Mill Size: SAG Mill 38 feet/11,58 m Ball Mills 24 feet/7,32 m Ore processed: Copper/Zinc Drive Rating: SAG Mill 20,1 MW, 9,23 rpm Ball Mills 11,2 MW, 11,38 rpmMineral processing operations present many challenges for automatic process control due to variations in unmeasured ore properties, material transport delays, and nonlinear response characteristics Control of SemiAutogenous Grinding(SAG) mill weight is an example of an important process that exhibits many of these aspectsSAG Mill Optimization using Model Predictive ControlJul 15, 2020 SAG mill – Large pieces of ore coming for grinding with a small addition (810% of the mill volume) of steel balls with a diameter of 100150 mm; In some cases, steel or castiron cymbals are used as a grinding medium, representing bodies in the form Ore Grinding MillsTypes and Classification – Mineral

(PDF) Influence of feed size on AG / SAG mill performance

The efficiency of the mill to break ore is a function of both the feed size distribution and the relative hardness of the ore When the feed size of a SAG mill becomes coarser, ie α r increases SAG Mills constitute a recent innovation in terms of ore processing SAG Mills can currently be up to 110 m in diameter by 46 m wide and are considered more ef fi cient than Ball Mills They can substantially reduce the crushing and milling process due to their large capacity and effi ciencyMill Circuit Pump ManualSAG mills grinding media includes some large and hard rocks, filled rate of 9% – 20% SAG mill grind ores through impact, attrition, abrasion forces In practice, for a given ore and equal processing conditions, the AG milling has a finer grind than SAG mills How does a sag mill work?What's the Difference Between SAG Mill and Ball Mill

capacity of sag mills in mineral ore processing

SAG mill ArchivesInternational Mining SAG mills are a key asset for mineral processing operations as one of the critical stages of extracting mineral out of ore and their continued stable operation is central to productivity the JKMRC says However the performance Service Online; Processing Copper Ore In Sag MillsMINING solutionAntamina Compania Minera Antamina SA Peru Project: One SAG Mill and 3 Ball Mill Drive Systems Capacity: SAG Mill 1000 t/h Ball Mills 1000 t/h Consultant: Bechtel, USA Mill Builder: FFE Minerals, USA Mill Size: SAG Mill 38 feet/11,58 m Ball Mills 24 feet/7,32 m Ore processed: Copper/Zinc Drive Rating: SAG Mill 20,1 MW, 9,23 rpm Ball Mills 11,2 MW, 11,38 rpmGearless Mill DrivesThe efficiency of the mill to break ore is a function of both the feed size distribution and the relative hardness of the ore When the feed size of a SAG mill becomes coarser, ie α r increases (PDF) Influence of feed size on AG / SAG mill performance

Outotec presents the world’s largest SAG mill Mineral

Outotec has recently been awarded a contract to deliver one of the largest grinding mills in the world The contract includes the design and manufacture of a Ø 40’ x 29’ SAG mill The mill will be driven by a Gearless Motor Drive (GMD) which at 280 MW is equal to the largest grinding mill power ever used in the mining industryApr 02, 2020 SAG mills are a key asset for mineral processing operations as one of the critical stages of extracting mineral out of ore, and their continued stable operation is central to productivity However, the performance of a SAG mill changes rapidly in response to conditions such as feed size and hardness as well as longerterm variability due to Mill Filling Prediction tool addresses productivity Single stage SAG Mills are very beneficial in reducing CAPEX for plants with a staged throughput approach When future tonnage is to be increased, the SAG Mill can feed downstream ball milling to boost capacity FullerTraylor SAG/AG Mills range in size from 43m through 122m in diameter with powers as high as 28,000 kWAutogenous and SemiAutogenous Mills

TECHNICAL NOTES 8 GRINDING R P King Mineral Tech

LG A mill power equation for SAG mills Minerals and Metallurgical Processing Feb 1990 pp5762 Gross power No load power Net power drawn by the charge (813) The net power is calculated from Net power KD25L e! c/ Watts (814) In equation 814, D is the diameter inside the mill liners and Le is the effective length of the mill including the Metallurgical ContentBall Charge Motion inside a SAG MillSAG Mill OperationSemi Autogenous Design FactorsSAG Mill Operation ExampleProcess Plant DescriptionSAG Mill Design and Specification Operating Problems Since CommissioningDesign Changes and Future Operating Strategies AG and SAG mills are now the primary unit operation for the majority of large grinding circuits, and form the SAG Mill Grinding Circuit DesignOre is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader The ore is conveyed, and lime is added (2) to raise the pH of the ore Following crushing through a jaw crusher (3), the ore is fed into the semi autogenous grinding (SAG) mill (4) along with water and steel ballsOre processing – Waihi Gold

Barry Wills' Blog: Keys to Best Practice Comminution

A history of 21st Century mineral processing, with occasional forays into travel and Cornwall Extra SAG mill capacity is a bonus while lack of capacity is a disaster John will show how to design workable grinding circuits on the same ore, using either single stage SAG milling, SAB grinding, SABC grinding, or HPGR precrushing followed by The ore mill processes ore from the mine by means of the following main concentrator areas: North/South Concentrators, Concentrator #3, and Concentrator #4 Processing design capacity (nameplate capacity) is described in brief (in 000 ton metric tons per day):PT Freeport IndonesiaOn the other hand, the surface area of the steel rod medium in the rod mill is smaller than that of the steel ball medium in the ball mill, so the utilization factor is lower than that of the ball mill of the same processing capacity Rod mills are often used in coarse grinding operations and are not suitable for fine crushing Buti in some What's the Difference Between Ball Mills and Rod Mills

SAG Mill goldcilplant

With the increasing of mineral processing plants' scale and the demand for automation, the manufacturing process and operation of SAG mill are more and more mature The running largest SAG mill is more than 13 meters in diameter, the full automatic control of the SAG mill has already been developed and applied, and now it is being gradually Is it advisable to use a SAG mill for small, say 2000 TPD concentrator operations? The processing, in this case, is a complex zinc/tin mineral and we are afraid a SAG would P80 produces too much fines (since the tin is to soft brittles) (tin cassiterite)The mineral is marmatite and casiteritreSAG Mill for Small Operation Grinding Classification With the increasing of mineral processing plants' scale and the demand for automation, the manufacturing process and operation of SAG mill are more and more mature The running largest SAG mill is more than 13 meters in diameter, the full automatic control of the SAG mill has already been developed and applied, and now it is being gradually SAG Mill goldcilplant

SAG mill Archives International Mining

With the new equipment, the plant expects to double its ore processing capacity and increase gold production, according to ’s delivery consists of the primary crushing station with a ® C160™ jaw crusher, one SAG mill and two ball mills Outotec has recently been awarded a contract to deliver one of the largest grinding mills in the world The contract includes the design and manufacture of a Ø 40’ x 29’ SAG mill The mill will be driven by a Gearless Motor Drive (GMD) which at 280 MW is equal to the largest grinding mill power ever used in the mining industryOutotec presents the world’s largest SAG mill Mineral The SAG mill was designed to treat 2,065 t h −1 of ore at a ball charge of 8% volume, total filling of 25% volume, and an operating mill speed of 74% of critical The mill is fitted with 80 mm grates with total grate open area of 766 m 2 ( Hart et al, 2001 )Grinding Circuit an overview ScienceDirect Topics

Process Testing Shows Increase in Mill Throughput

Mar 25, 2019 Management has a targeted timeline at Tahuehueto to be producing with its own onsite mineral processing plant, with a designed capacity of at least 1,000 tonnes per day, Q3Q4 2019Ore is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader The ore is conveyed, and lime is added (2) to raise the pH of the ore Following crushing through a jaw crusher (3), the ore is fed into the semi autogenous grinding (SAG) mill (4) along with water and steel ballsOre processing – Waihi GoldMay 15, 2014 SAG mills are primarily used at gold, copper and platinum mines with applications also in the lead, zinc, silver, alumina and nickel industries The largest SAG mill is 42' in diameter, powered by a 28 MW (38,000 HP) motor AUTOGENOUS GRINDING MILL SAG They are socalled due to the selfgrinding of the oreMineral Processing SlideShare

SAG Mill for Small Operation Grinding Classification

Is it advisable to use a SAG mill for small, say 2000 TPD concentrator operations? The processing, in this case, is a complex zinc/tin mineral and we are afraid a SAG would P80 produces too much fines (since the tin is to soft brittles) (tin cassiterite)The mineral is marmatite and casiteritreLG A mill power equation for SAG mills Minerals and Metallurgical Processing Feb 1990 pp5762 Gross power No load power Net power drawn by the charge (813) The net power is calculated from Net power KD25L e! c/ Watts (814) In equation 814, D is the diameter inside the mill liners and Le is the effective length of the mill including the TECHNICAL NOTES 8 GRINDING R P King Mineral TechA history of 21st Century mineral processing, with occasional forays into travel and Cornwall Extra SAG mill capacity is a bonus while lack of capacity is a disaster John will show how to design workable grinding circuits on the same ore, using either single stage SAG milling, SAB grinding, SABC grinding, or HPGR precrushing followed by Barry Wills' Blog: Keys to Best Practice Comminution

Major Mines Projects Palmarejo Mine

Crushed ore is directly fed to the grinding circuit from the crushed ore stockpile The grinding circuit consists of a SAG mill and a Ball mill operating in a closed circuit with a battery of cyclones for classification The cyclone battery consists of nine 80inch Krebs cyclones with an apex opening of 425 inches and vortex opening of 6 inchesAug 27, 2013 As of the end of 2014, ALROSA’s mineral processing capacity totals 359 million tons of ore per year Plants 12 (Udachny MPD) and 14 (Aikhal MPD), with capacities of 12 and 10 million tons of ore per year, respectively, are the largest of their kind in ALROSA and worldwideMineral processing AlrosaIncluding maintanance of sag and ball mills grinding mills,and mineral processing maintanance of sag and ball mills another high capacity get quote001ag sag mills bulgariagsag mills are normally used to grind mineral processing plantsn some ore bodies, of these mills had the capacity Sag Mills And Ball Mills Pdf Fact Jeugd Noord

Minding the Grind: Maintenance Options to Keep SAG Mills

Multotec, a SouthAfrica based supplier of mineral processing equipment, recently highlighted the capabilities of its SAG mill trommel screen line, describing it as a viable alternative to vibrating screens in SAG mill scalping applications, with features that offer high throughput and extended wear life