Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

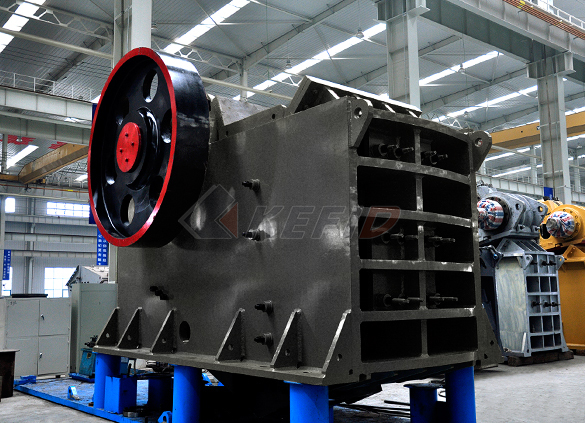

C6X series jaw crusher

-

JC series jaw crusher

-

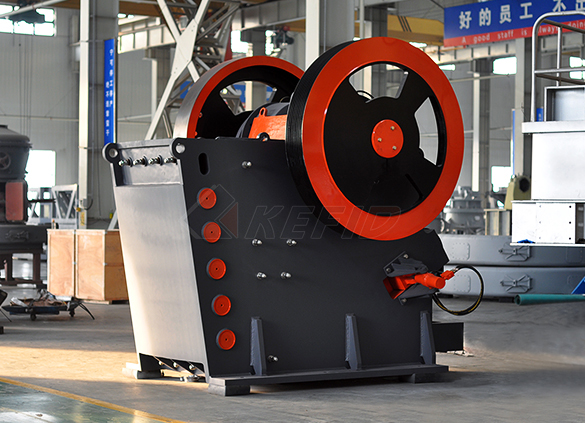

Jaw crusher

-

HJ series jaw crusher

-

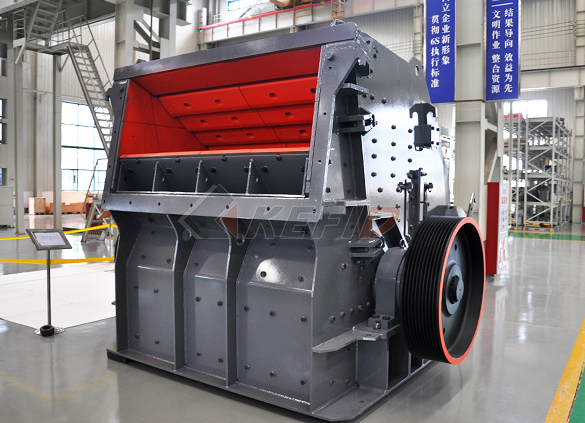

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

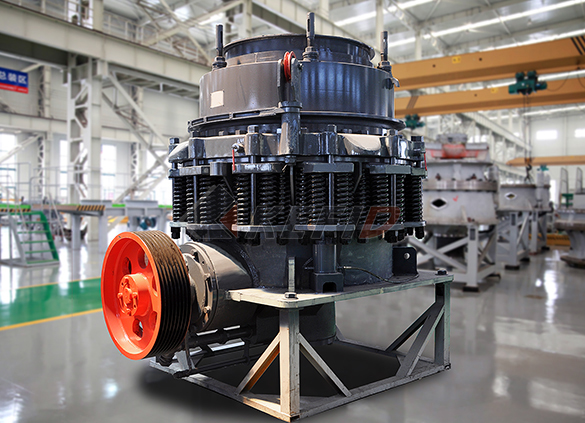

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

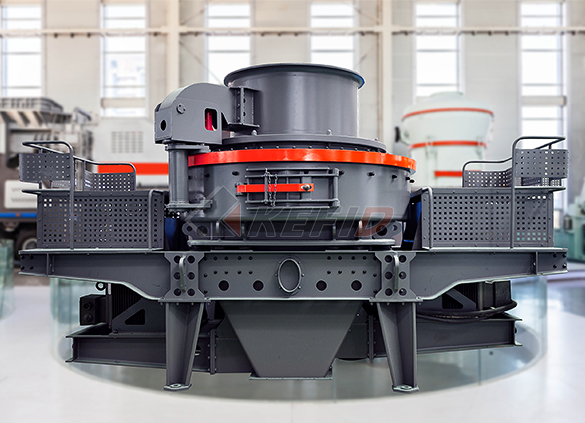

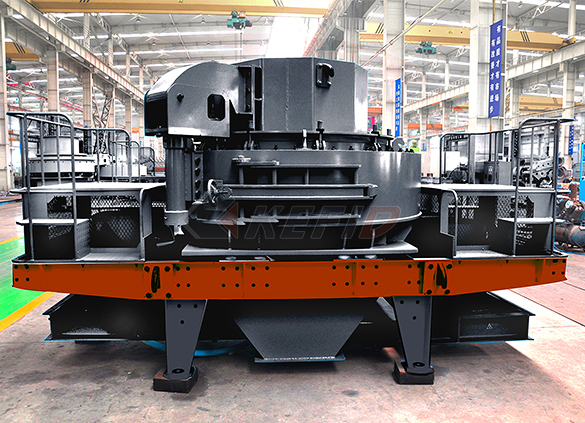

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

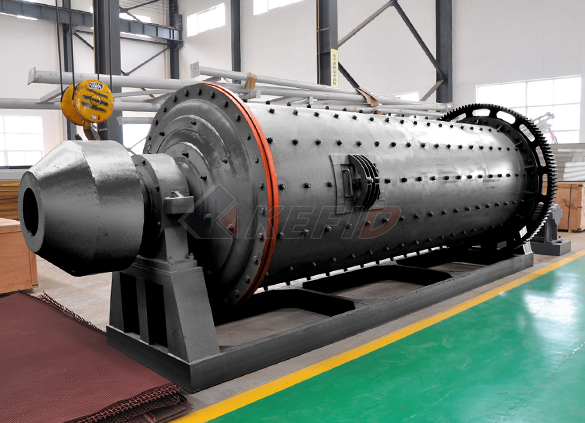

Ball mill

-

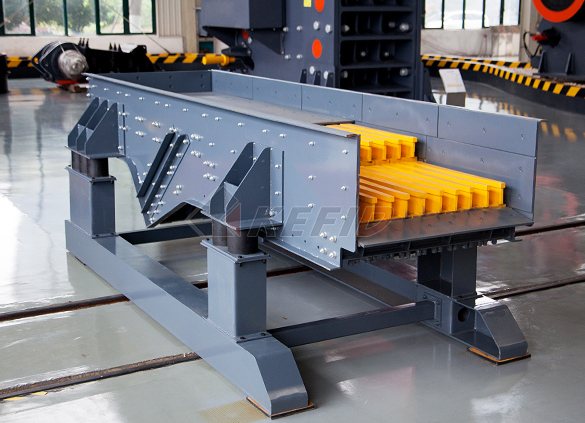

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

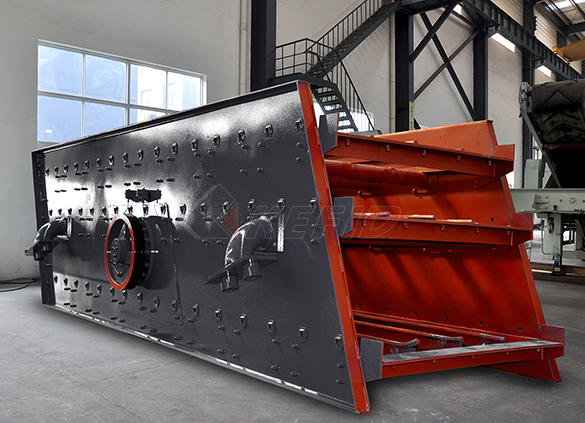

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

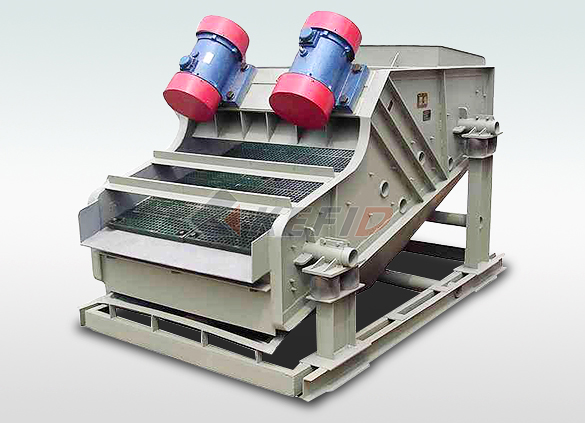

High frequency screen

Crushing in Mineral Processing

In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surface Less abrasive and softer rocks or stones Crushing Mineral Processing Crushing Mineral Processing is the first step of comminution preceding grinding, flotation and leaching Crushing comes just after inpit blasting and continues the fragmentation processCrushing Mineral ProcessingCrushing process Crushing is the process of breaking down large solid material, such as pieces of ore or coal, in order to reduce their size to a specified one, to ensure a certain granulometric composition of fractions As a result of crushing, the mineral grains open up to a given degreeCrushing Methods and thier Classification – Mineral Processing

Crushing of Ores and Rocks in Mineral Processing

In minerallurgy, crushing is the first mechanical step in the comminution process It allows reducing the mined ore size (up to 1 meter), until an acceptable size to undergo downstream treatment Therefore, it places in the exit of the MineMar 04, 2017 Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the (PDF) SIZE REDUCTION BY CRUSHING METHODSJul 01, 2015 Comminution in the mineral processing plant takes place in a sequence of crushing and grinding (and/or milling) Crushing reduces particle size of COMMINUTION: Liberation, Crushing, Grinding

Crushing Grinding – The Anchor House, Inc

Sep 09, 2016 The purpose of crushing and grinding is to reduce the size of the potential ore particles to that where there is sufficient REE mineral liberation and the size/size distribution is suitable for the chosen downstream mineral recovery processThe table below shows the steps from crushing to upgrading Crushing of minerals Crushing is the most invested operation in mineral processing The goal of crushing is to produce mineral fractions of required particle for subsequent benefication process The Industry Crushing Equipmetn Mineral Processing8/04 Mineral Products Industry 11192 1 11192 Crushed Stone Processing and Pulverized Mineral Processing 111921 Process Description 24, 25 Crushed Stone Processing Major rock types processed by the crushed stone industry include limestone, granite, dolomite, traprock, sandstone, quartz, and quartzite Minor types include calcareous marl,AP42 Section 11192 Crushed Stone Processing and

Crushing and Screening for Mineral Processing Success

What does an efficient crushing and screening setup look like in order to get the most out of your mineral processing system? Why is ore sorting becoming a more soughtafter method in the mineral processing industry? Throughout this paper, we will explore the principles of ore sorting and how crushing and screening can impact ore sorting performanceJul 01, 2015 In minerals processing most of the minerals are very finely disseminated or associated with the waste (or the “gangue”) fraction of ore Crushing is usually a dry process, and is performed COMMINUTION: Liberation, Crushing, GrindingThe Difference between Crushing and Grinding in mineral processing Both crushing and grinding are size reduction processes They are known as milling operations Introduction The size reduction operation in the plant takes place as a sequence of crushing and grinding processesCrushing Vs Grinding Minerallurgy

Crushing Grinding – The Anchor House, Inc

Sep 09, 2016 Each possible mineral recovery process has a certain size range of best performance, and the final product of the crushing/grinding circuit must match the chosen process size requirements Proper grinding is critical in order to get good metallurgical test results, as the entirety of downstream processing is dependent on optimal grinding and Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by (PDF) Overview of Mineral Processing MethodsMar 13, 2021 In this report, the Global Crushing, Screening, and Mineral Processing Equipment market is valued at USD XX million in 2019 and is expected to reach USD XX million by the end of Global Crushing, Screening, and Mineral Processing

Mineral Processing SlideShare

May 15, 2014 Mineral Processing Jaw crusher gyratory Crusher beneficiaton roll crusher screening separation classifier grinding crushing law dry grinding wet grinding Ned Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertisingMineral Processing Seneca has vast experience in the processing of minerals, specifically in the Northern Cape iron ore and manganese fields Seneca offers MultiStage crushing and screening equipment specifically suited to the tough, highly abrasive conditionsMineral Processing Seneca Seneca CrushingHowever,there are quite a few mineral processing plants with the disadvantage of incompatible crushing and grinding equipment and technology: guaranteeing the size of crushed products cannot guarantee the output, while guaranteeing the output may lead that the Some Problems in the Crushing and Grinding Stage of

Mineral Processing an overview ScienceDirect Topics

Mining and mineralprocessing industries producing lithium minerals, metals, and salts contribute to the lithium burden in the environment The processing of lithiumcontaining minerals such as spodumene, in general, comprises crushing, wet grinding in a ball mill, sizing, gravity concentration, and flotation using a fatty acid (oleic acid) as Crushing, Screening, and Mineral Processing Equipment Market Outlook 2025 The global crushing, screening, and mineral processing equipment market growth was valued at $191212 million in 2017, and is projected to reach $33,1164 million by 2025, growing at Crushing, Screening and Mineral Processing Equipment The comminution is an important unit operation in mineral processing, this process requires application of forces Mechanical comminution can be accomplished in mainly 2 ways 1 Crushing: the most used crushing machine are the jaw crusher, cone crusher, impact crusher, and hammer crusher 2 Grinding: crushed material can be further ground in grinding mills like ball mill, rod mill, hammer Equipment for Mineral Comminution Process Mineral Processing

Crushing and Screening for Mineral Processing Success

What does an efficient crushing and screening setup look like in order to get the most out of your mineral processing system? Why is ore sorting becoming a more soughtafter method in the mineral processing industry? Throughout this paper, we will explore the principles of ore sorting and how crushing and screening can impact ore sorting performance8/04 Mineral Products Industry 11192 1 11192 Crushed Stone Processing and Pulverized Mineral Processing 111921 Process Description 24, 25 Crushed Stone Processing Major rock types processed by the crushed stone industry include limestone, granite, dolomite, traprock, sandstone, quartz, and quartzite Minor types include calcareous marl,AP42 Section 11192 Crushed Stone Processing and The table below shows the steps from crushing to upgrading Crushing of minerals Crushing is the most invested operation in mineral processing The goal of crushing is to produce mineral fractions of required particle for subsequent benefication process The Industry Crushing Equipmetn Mineral Processing

Mineral Processing an overview ScienceDirect Topics

Mining and mineralprocessing industries producing lithium minerals, metals, and salts contribute to the lithium burden in the environment The processing of lithiumcontaining minerals such as spodumene, in general, comprises crushing, wet grinding in a ball mill, sizing, gravity concentration, and flotation using a fatty acid (oleic acid) as At most metallic mineral processing plants, each process operation requires several types of equipment A single crushing operation likely includes a hopper or ore dump, screen(s), crusher, surge bin, apron feeder, and conveyor belt transfer points Emissions from these various pieces of equipment are often ducted to a single control device1124 Metallic Minerals ProcessingHowever,there are quite a few mineral processing plants with the disadvantage of incompatible crushing and grinding equipment and technology: guaranteeing the size of crushed products cannot guarantee the output, while guaranteeing the output may lead that the Some Problems in the Crushing and Grinding Stage of

Mineral Processing Laron

Mineral processing covers the full gamut of crushing, transporting, rendering, enriching and refining the ore into product A wide range of skills are required for a truly full solution services provider to safely tear down and inspect damaged or worn equipment, access the best repair strategy, and where necessary, remove, package and transport the equipment to a Laron offsite facility for Crushing, Screening, and Mineral Processing Equipment Market Outlook 2025 The global crushing, screening, and mineral processing equipment market growth was valued at $191212 million in 2017, and is projected to reach $33,1164 million by 2025, growing at Crushing, Screening and Mineral Processing Equipment McLanahan’s line of minerals processing equipment can be used in all stages of the process From crushing and sizing to sampling and dewatering, each piece of McLanahan equipment ensures that you will recover the maximum amount of valuable mineralsMining McLanahan

Mineral Processing Seneca Seneca Crushing

Mineral Processing Seneca has vast experience in the processing of minerals, specifically in the Northern Cape iron ore and manganese fields Seneca offers MultiStage crushing and screening equipment specifically suited to the tough, highly abrasive conditionsIn particular, in the process of beneficiation, both of them basically take the selected feed minerals containing less gangue minerals as the sorting object, and both use the biggest difference in mineral selectivity, which makes the two in the whole process both play a good role in the process Based on the iron ore processing experience and Iron Ore Processing,Crushing,Grinding Plant Machine Desgin The crushing process often requires different stages of grinding, since there is no crusher or mill capable of converting large mineral formats into micronized fines Thus, our range of crushers and mills covers the whole size reduction process, from the primary crushing stage to the refining grindingVerdés machines for mineral processing, grinding and crushing

What We Do Mineral Processing Process 26

We Deliver Projects Process 26 delivers minerals processing projects, from initial concept development through design and construction to existing plant optimisation and process improvement With extensive experience across a broad range of processes, the company employs practical engineering to deliver successful projects that are reliable and maintainableMineral processing Mineral processing Dewatering: Concentrates and tailings produced by the methods outlined above must be dewatered in order to convert the pulps to a transportable state In addition, the water can be recycled into the existing water circuits of the processing plant, greatly reducing the demand for expensive fresh water Filtration is the separation of a suspension into a Mineral processing Dewatering Britannica