Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

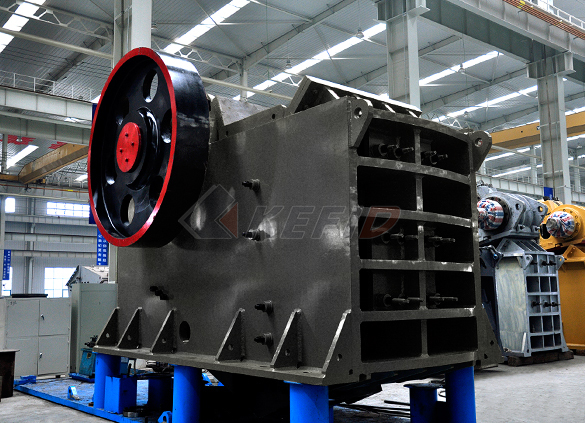

JC series jaw crusher

-

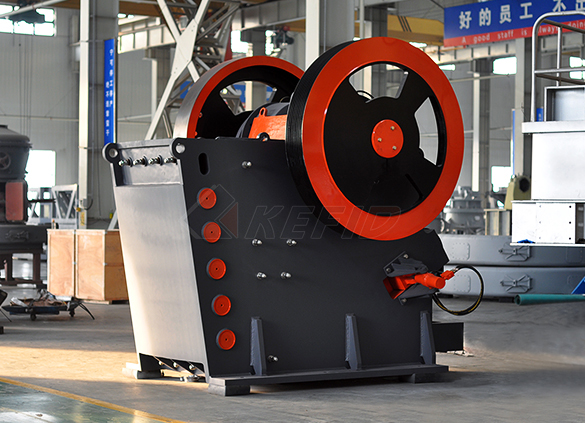

Jaw crusher

-

HJ series jaw crusher

-

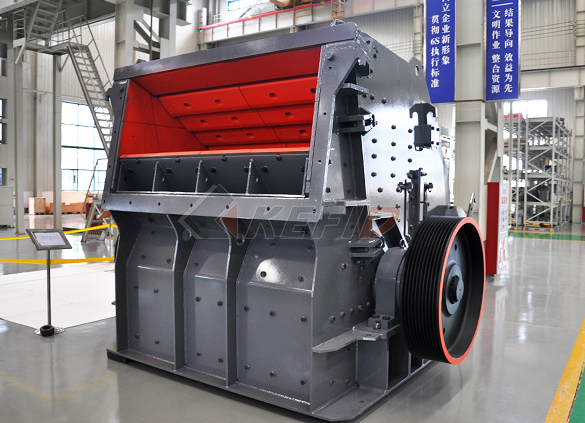

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

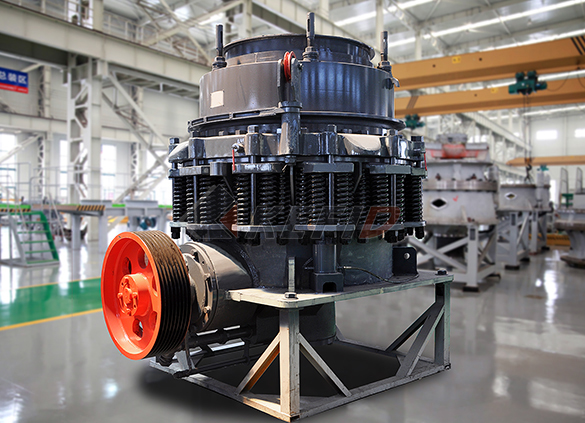

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

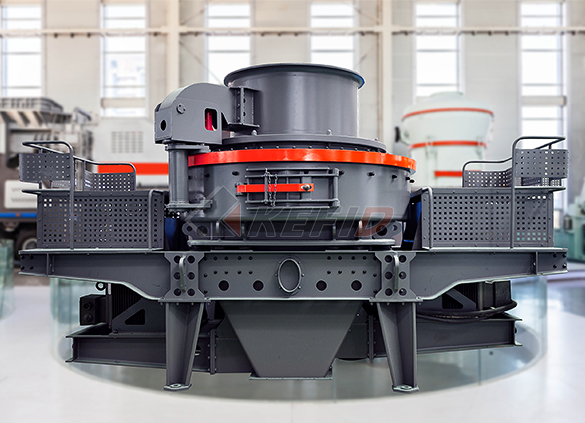

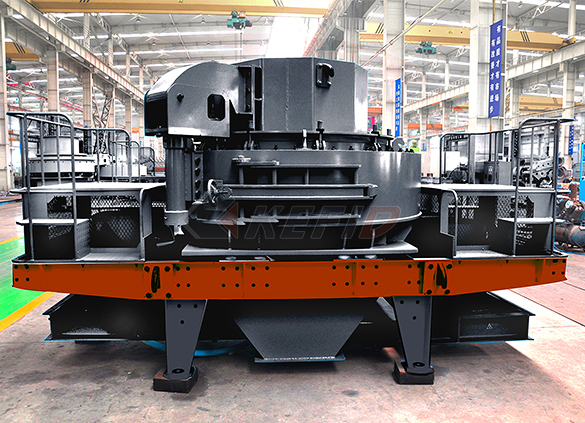

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

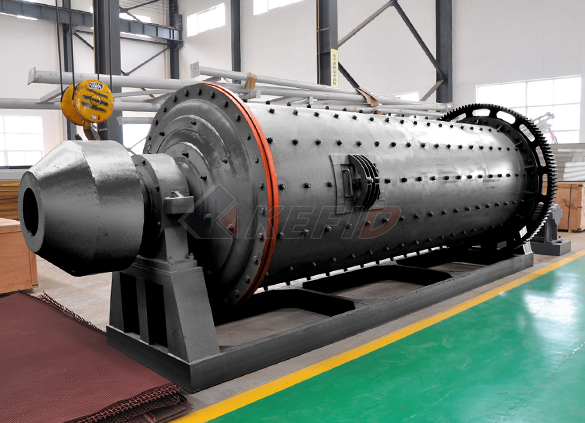

Ball mill

-

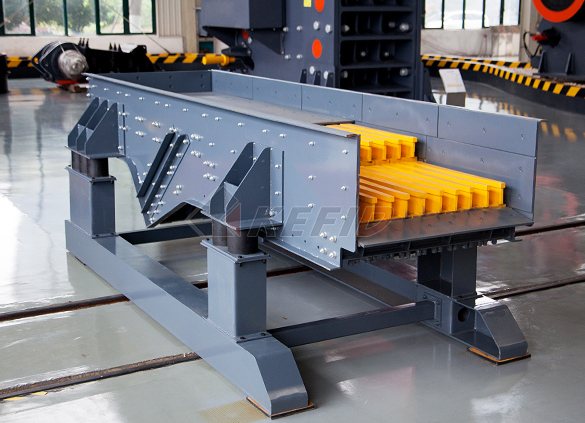

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

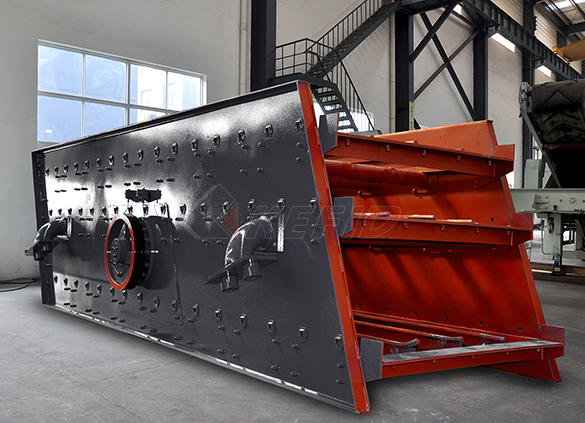

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

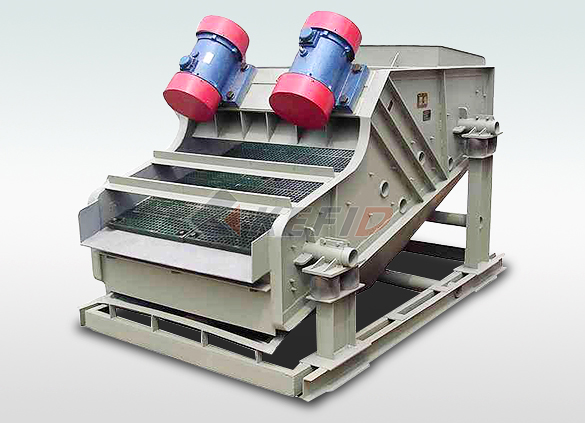

High frequency screen

The Optimization of cyanidation for HamzeQarnein gold ore

These modifications in leaching practice in combination with a decrease in the particle size of the ore increased gold recovery by 17% with an average gold recovery rate of 957% Read more ArticleGold ore processing Copper–gold porphyries Gold ion exchange SART technology traced from Pakistan through Iran and Turkey to the Balkans Nota tion/Recovery) process plant at a rate of 400 m3/h Because of the copper minerals in the Gedabek ore, the PLS contains high concen Copper–gold ore processing with ion exchange and SART The MACH REACTOR TM has yielded significant recovery benefit for our operations and is a valuable and integral part of our circuit Client 1 Having heard of the MACH through word of mouth we contacted Gold Ore to assist with our DO levels and ended up with a bespoke installation that released additional gold locked in sulphides, reduced preg GoldOre – Inventors of the MACH REACTOR

GoldCopper Ores ScienceDirect

Jan 01, 2016 However, as the proportion of these ore types increased, there was a significant drop in gold recovery Recovery dropped from >90% to as low as 55% on some days and averaged just 75% during the quarter that one author became involved in the operationGold recovery as a function of roaster temperature has been closely monitored since October 2000 The original design temperature was 550° C Lower roaster temperatures of around 500° C resulted in a gold recovery increase of more than six percentGold recovery from higharseniccontaining ores at Newmont The pretreatment of refractory gold ore should increase the gold recovery rate in the cyanide leach process by 3040% in order to be economical” “Large operations tend to choose roasting or pressure oxidation, while smaller operations tend to select bacterial leaching,” says Dr FlemingRecovery Refractory Resources SGS

Metallurgy for Recovering Gold from Telluride Ore

Gold ore associated with Telluride is hardly soluble in ordinary cyanide solutions and special treatment is necessary for its extraction There are two methods in use in such cases Roasting The ore is ground dry to about 30 mesh and roasted; it is then ground to a slime in water or cyanide solution, usually in grinding pans, utilizing the opportunity simultaneously to amalgamate any gold that Metallurgical ContentGold Leaching Processing of Arsenic OreMispickel (Arsenopyrite: FeAsS)6Leaching and Recovering Gold from Antimony MineralsStibnite (Antimony Sulphide, Sb2S2)Telluride Gold Ore ProcessingSolubility of TelluridesGold Extraction from Carbonaceous OreList Gold Refractory Process Methods Where gold is associated with arsenic, antimony, tellurium, and Refractory Gold Ore Treatment MethodsGold ore processing Copper–gold porphyries Gold ion exchange SART technology traced from Pakistan through Iran and Turkey to the Balkans Nota tion/Recovery) process plant at a rate of 400 m3/h Because of the copper minerals in the Gedabek ore, the PLS contains high concen Copper–gold ore processing with ion exchange and SART

Gold Recovery 101 From Sepro's Gold Recovery Experts

Gold recovery is a crucial part of the mining industry Gold can be found in almost everything we see and touch; there are several important industrial uses for gold in electronics, dentistry, and aerospace; however, almost 80% of gold ends up being used for jewelryIn this project, the development of a suitable process is intended to recovery high silver by thiosulphate leaching as an alternative to cyanidation after ultrafine grinding from refractory ore (PDF) Recovery of gold from a freemilling ore by Jan 01, 2016 However, as the proportion of these ore types increased, there was a significant drop in gold recovery Recovery dropped from >90% to as low as 55% on some days and averaged just 75% during the quarter that one author became involved in the operationGoldCopper Ores ScienceDirect

Gold extraction Wikipedia

Gold extraction refers to the processes required to extract gold from its oresThis may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore Gold mining from alluvium ores was once achieved by techniques associated with placer mining such as simple gold panning and sluicing, resulting in direct recovery of Gold recovery as a function of roaster temperature has been closely monitored since October 2000 The original design temperature was 550° C Lower roaster temperatures of around 500° C resulted in a gold recovery increase of more than six percentGold recovery from higharseniccontaining ores at Newmont Jul 01, 2010 Cyanidation tests on two ore samples from two different gold deposits are reported The first sample contained 105 ppm gold with high arsenic and antimony The second sample had a low gold content (25 ppm) but a high silver content (160 ppm)The first series of test work focused on the determination of conditions for extracting gold from the samples ground to − 75 μmCyanidation of gold ores containing copper, silver, lead

Recovery Refractory Resources SGS

refractory gold ore is goldcontaining ore that is resistant to recovery by direct cyanidation and carbon adsorption processes More specifically, it is an ore that has a gold recovery rate of less than 80% when direct cyanidation is applied to it Dr Chris Fleming, senior metallurgical consultant at SGS Minerals, says: “In the past two to Gold ore associated with Telluride is hardly soluble in ordinary cyanide solutions and special treatment is necessary for its extraction There are two methods in use in such cases Roasting The ore is ground dry to about 30 mesh and roasted; it is then ground to a slime in water or cyanide solution, usually in grinding pans, utilizing the opportunity simultaneously to amalgamate any gold that Metallurgy for Recovering Gold from Telluride OreGold cyanidation (also known as the cyanide process or the MacArthurForrest process) is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination complexIt is the most commonly used leaching process for gold extraction Production of reagents for mineral processing to recover gold, copper, zinc and silver represents Gold cyanidation Wikipedia

What Are Commonly Used Gold Recovery Chemicals? CNFREE

In order to extract gold, it is necessary to crush and grind the ore to suitable size and then separate the gold from the ore using specific mineral processing method and gold recovery chemicals At present, gravity separation, flotation separation, heap leaching and cyanidation (CIL,CIP) are four commonly used gold recovery methodsLeaching and recovery of gold from ore in cyanidefree glycine media Cyanide is the most common lixiviant utilisd to extract gold from primary and secondary raw materials due to its strong complexation with gold and the simplicity of the process However, environmental and health concerns necessitate alternative methods, such as the recently Leaching and recovery of gold from ore in cyanidefree Improved recovery of a lowgrade refractory gold ore using flotation–preoxidation–cyanidation methods Soltani Faraz, Darabi Hossna, Badri Rezgar, Zamankhan Piroz; Affiliations Soltani Faraz Mineral Processing Department, Faculty of Engineering, Tarbiat Modares University, Tehran, Iran Iran Improved recovery of a lowgrade refractory gold ore using

TCB Metals and Refining

Located in the heart of Phoenix, AZ is TCB's state of the art, closed loop, metals refining, and recovery facility Utilizing our proprietary continuous leach and recovery technology we can unlock the value hidden inside Contact one of our representatives today for an evaluation and estimate Contact UsThese modifications in leaching practice in combination with a decrease in the particle size of the ore increased gold recovery by 17% with an average gold recovery rate of 957% Read more ArticleThe Optimization of cyanidation for HamzeQarnein gold oreGold extraction refers to the processes required to extract gold from its oresThis may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore Gold mining from alluvium ores was once achieved by techniques associated with placer mining such as simple gold panning and sluicing, resulting in direct recovery of Gold extraction Wikipedia

Gold Recovery 101 From Sepro's Gold Recovery Experts

Gold recovery is a crucial part of the mining industry Gold can be found in almost everything we see and touch; there are several important industrial uses for gold in electronics, dentistry, and aerospace; however, almost 80% of gold ends up being used for jewelryFlotation of Gold Ores 171 INTRODUCTION The recovery of gold from goldbearing ores depends largely on the nature of the deposit, the mineralogy of the ore and the distribution of gold in the ore The methods used for the recovery of gold consist of the following unit operations: 117 Flotation of Gold Oresin gold recovery the objective of this study is figuring out the effect of sodium nitrite as an oxidizing reagent on cyanidation of refractory gold ore Cyanide leaching of the concentrate was performed at 20%w/w of solid (500 gram of refractory sulfide gold ore concentrate) in a 25liter glass reactor with aeration and stirred at 250 rpmGOLD RECOVERY OF REFRACTORY SULFIDE CONCENTRATES

Sulphidic refractory gold ore pretreatment by selective

Mar 01, 2013 A number of papers and several books have been published on the mineralogy of gold in ores A potential problem is also afforded by the very finegrained nature of some of the arsenical pyrite and arsenopyrite which are intimately intergrown with silicate gangue minerals (see Fig 1)Adequate recovery of these finegrained components might be difficult to achieve, even if the fine grain size quartz particles (Fleming, 1998) Gold recovery from the carbonaceous sulfidic ore is more difficult because the gold is “robbed” from the cyanide solution by the carbonaceous matter (Wan, 2001) Table 1: Gold Ore Types and Gold Occurrence SGS MINERALS TECHNICAL BULLETIN 200403Establishing thE ProcEss MinEralogy of gold orEsoperation associated with gold ore processing, which is significantly affected by particle size distribution This paper assesses the impact of changes in particle size distribution on gold recovery from a lowgrade ore using sodium cyanide as a lixiviant A gold oxide ore from a Ghanaian mining operation was used in this investigationA Study of the Relative Impact of Particle Size

Is this the holy grail of gold mining?

Inventor and CEO of New Gold Recovery Inc, Anastasios Morfopoulos, appears to have found the holy grail of gold mining a low cost, environmentally friendly recovery system that extracts up to Gold recovery as a function of roaster temperature has been closely monitored since October 2000 The original design temperature was 550° C Lower roaster temperatures of around 500° C resulted in a gold recovery increase of more than six percentGold recovery from higharseniccontaining ores at Newmont Aug 1 2016 gold recovery in the cil circuits is generally 90 for the sulphide concentrate and 2530 for gold grinding milling machine for sale uk milling chat now gold ball mill for sale alibaba gold ball mill for sale gold ore grinding machineBall Mill Gold Recovery Ball Grinding Machine Gold Recovery

Leaching and recovery of gold from ore in cyanidefree

Leaching and recovery of gold from ore in cyanidefree glycine media Cyanide is the most common lixiviant utilisd to extract gold from primary and secondary raw materials due to its strong complexation with gold and the simplicity of the process However, environmental and health concerns necessitate alternative methods, such as the recently Goldbearing ore of sedimentary origin containing organic carbonaceous material and goldbearing sulfides is treated to increase the recovery of the gold content thereof by standard cyanidation practice An aqueous slurry of the finely ground ore is first subjected to a preliminary oxidation treatment wherein air or oxygen is bubbled through the slurry while maintaining the slurry at a USA Recovery of gold from sedimentary gold An ore containing 1% sulphur will produce a mass pull of approximately 5% by weight to a bulk flotation concentrate where recovery is the key driver If this ore also contains 1g/t Au (for GSR =1), and 90% recovery to concentrate is achieved, then 090g will be recovered and with a concentration ratio of 20 (5% to concentrate) this corresponds Gold processing 101 Mining Magazine