Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

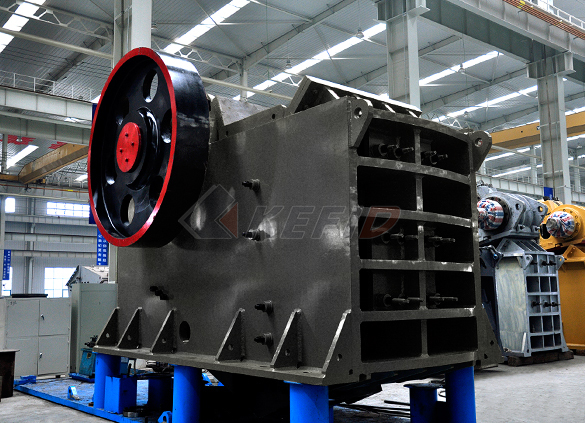

JC series jaw crusher

-

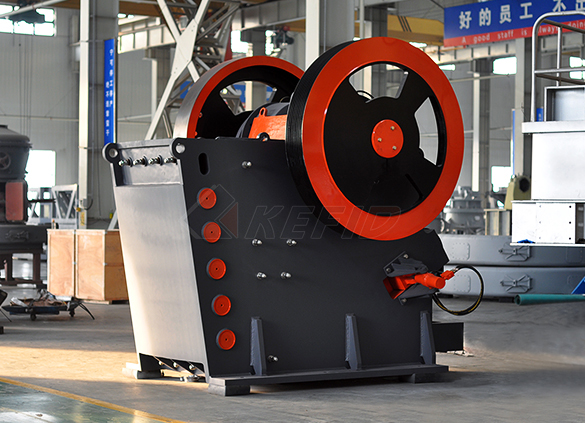

Jaw crusher

-

HJ series jaw crusher

-

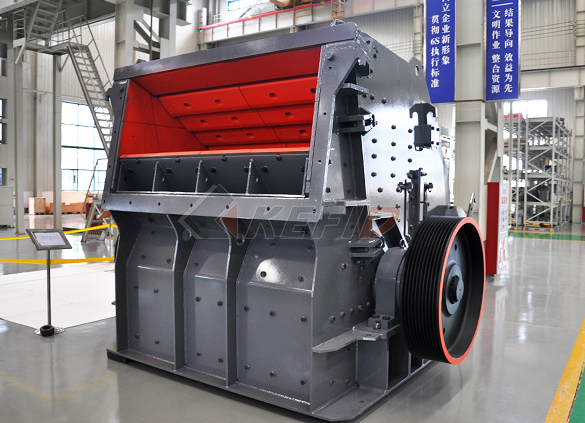

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

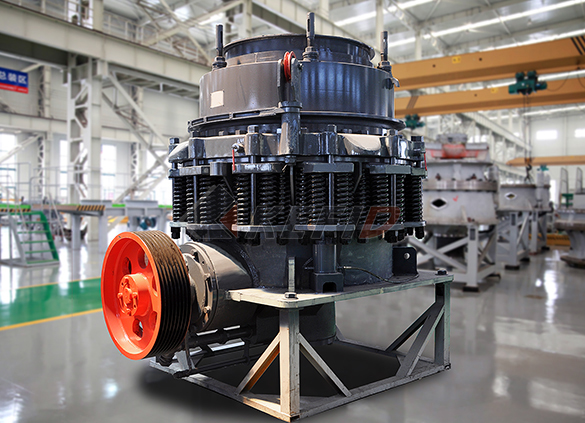

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

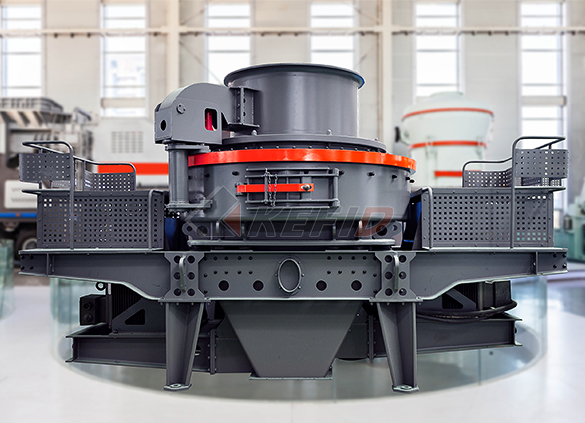

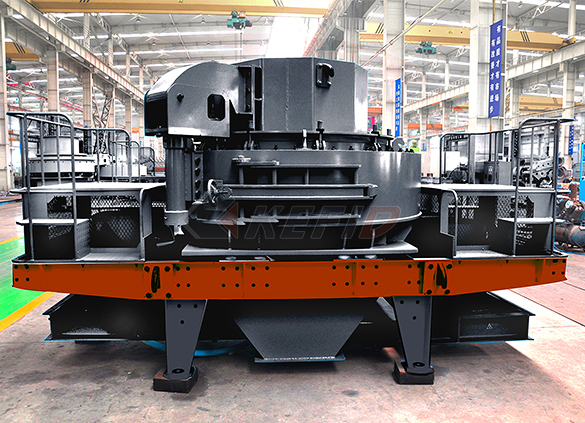

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

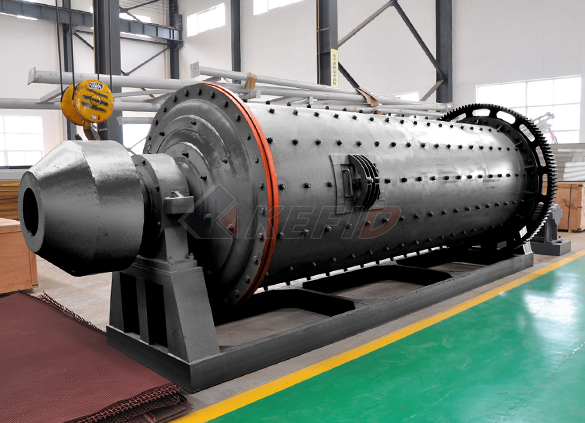

Ball mill

-

GF series feeder

-

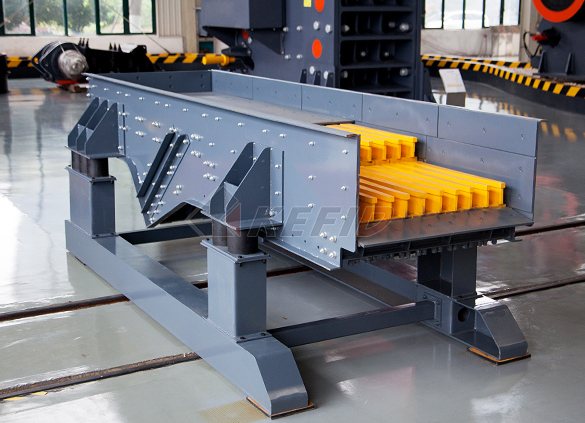

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

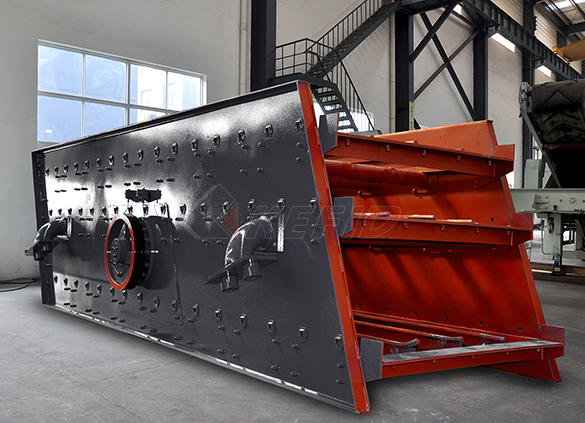

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

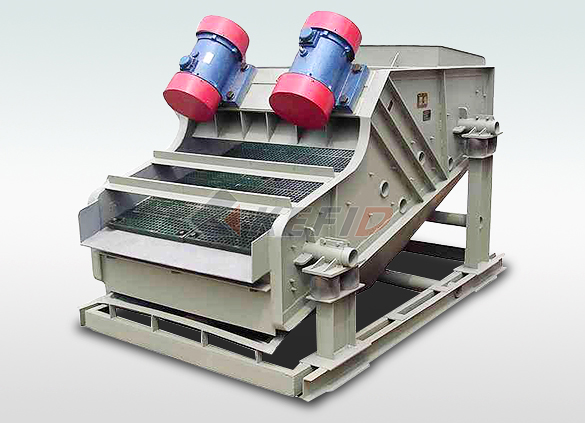

Electromagnetic vibrating feeder

-

High frequency screen

Coal Handling Plant, Coal Handling system,

Our handling system can significantly boost your production capacity and effectiveness of your daily operation Our systems are a great way to transfer large amounts of coal over long distances They have the capability of significantly cutting down the cost of your production because they have very low power consumption rateCost analysis of a coalfired power plant using the NPV The maintenance and insurance costs are taken to be 15 and 1 % of the total capitalinvestment obtained from the literature The coal storage fuel handling system and fumetreatment costs are neglected in the Comparing Coal Handling System Costscost of coal handling system Coal handling system sales set to grow at in as ,global coal handling system sales are set to grow at 42% yoy in 2021, and surpass us$ 65 billion in valuation demand from thermal power generation will continue to sustain momentum, howevercost of coal handling system zlatolevneturnovcz

Gerobotiseerd systeem voor het lossen palletiseren van

Met het Copal systeem en beschikbare medewerkers kunnen piekmomenten worden opgevangen en een flexibel, betrouwbaar inbound proces worden gewaarborgd Aanzienlijk betere arbeidsomstandigheden zorgen tevens voor een belangrijk voordeel in DE system is an air quality improvement system used in coal handling plant to improve breathable air quality and safety by removing dust particle from the air/environment It works on the basic formula of collection, separation and filtrationCoal Handling System Coal Handling Plant In Coal handling is part of the larger field of bulk Material handling, and is a complex and vital part of the CPP FUEL HANDLING SYSTEM Coal delivery equipment is one of the major components of plant cost The various steps involved in coal handling are as follows: 1 Coal delivery 2 Unloading 3 Preparation 4 Transfer 5 Outdoor storageFuel Handling System BrainKart

Coal handling plant in a thermal power generating

13102020 Introduction to Coal handling plant In a coal based thermal power plant, the initial process in the power generation is “Coal Handling”So in this article i will discuss the overall processes carried out at a Coal Handling plant in a coal based thermal power generating stationcost of coal handling system,Our company is a largescale heavy enterprise that taking heavy mining machinery manufactory as main products and integrated with scientific research, production, and marketing We are concentrating on producing and selling machines such as jaw crusher, cone crusher, hammer crusher, ball mill, sand maker, mobile crushing plantCost Of Coal Handling System christinakratschdeAsh handling systems have experienced gradual changes since the 1970s, but the Kingston event triggered the US Environmental Protection (EPA) to create new regulations for ash handling that will Ash Handling Options for CoalFired Power Plants

Coal Handling Process YouTube

19102016 Proses coal handling di pltu10012021 @article{osti, title = {Comparing coal handling system costs}, author = {Lehto, J M}, abstractNote = {Good maintenance practices and proactive planning are essential to ensure coal handling equipment performance, but a look at the entire cost of handling coal has yielded some surprising conclusions Optimizing a given system can be challenging and Comparing coal handling system costs (Journal Good maintenance practices and proactive planning are essential to ensure coal handling equipment performance, but a look at the entire cost of handling coal has yielded some surprising conclusions Optimizing a given system can be challenging and requires a close analysis of the total cost This article addresses the cost analysis of the coal handling system Comparing coal handling system costs

comparing coal handling system costs

Comparing coal handling system costs Power 01031996 Good maintenance practices and proactive planning are essential to ensure coal handling equipment performance, but a look at the entire cost of handling coal Get Price depreciation rates as Coal represents a significant proportion of all dry bulk, and handling and transportation of this challenging material is a major consideration It is particularly important to make sure that handling equipment is reliable in the long term because breakdowns can lead to considerable downtime, reductions in efficiency and unforeseen costsImprovingAssetAvailabilityToReduceCoal DE system is an air quality improvement system used in coal handling plant to improve breathable air quality and safety by removing dust particle from the air/environment It works on the basic formula of collection, separation and filtrationCoal Handling System Coal Handling Plant In

Fuel Handling System BrainKart

Coal handling is part of the larger field of bulk Material handling, and is a complex and vital part of the CPP FUEL HANDLING SYSTEM Coal delivery equipment is one of the major components of plant cost The various steps involved in coal handling are as follows: 1 Coal delivery 2 Unloading 3 Preparation 4 Transfer 5 Outdoor storage02092013 DESIGN OF INPLANT COAL HANDLING SYSTEM POINTS TO REMEMBER : 1 Simple and sound, requiring minimum operations and transportation 2 No double handling of coal in plant 3 Handling unit should be centralized to facilitate inspection and maintenance 4 Electric motors can be used as driver of mechanism 5Coal and Ash Handling SlideShareA coal preparation plant (CPP; also known as a coal handling and preparation plant (CHPP), coal handling plant, prep plant, tipple or wash plant) is a facility that washes coal of soil and rock, crushes it into graded sized chunks (sorting), stockpiles grades preparing it for transport to market, and more often than not, also loads coal into rail cars, barges, or shipsCoal preparation plant Wikipedia

Development Of Condition Based Maintenance For Coal

large tonnage coal handling installations, coal car unloading, storage, reclaim system depend on the proper application of feeders The various types of feeders being used in coal handling plant are: 1 Apron feeder 2 Belt feeder 3 Rotary feeders 4 Reciprocating feeders 5 Screw feeders 6 Revolving disc feeders 7 Vibrating feeders01022013 Four years after more than one billion gallons of coal ash slurry spilled from a storage pond at the Kingston Power Plant in eastern Tennessee, environmental groups are still waiting for the US Coal Ash Handling Storage: Shifting Good maintenance practices and proactive planning are essential to ensure coal handling equipment performance, but a look at the entire cost of handling coal has yielded some surprising conclusions Optimizing a given system can be challenging and requires a close analysis of the total cost This article addresses the cost analysis of the coal handling system at the Northern States Power Co Comparing coal handling system costs Semantic

Comparing Coal Handling System Costs

Cost analysis of a coalfired power plant using the NPV The maintenance and insurance costs are taken to be 15 and 1 % of the total capitalinvestment obtained from the literature The coal storage fuel handling system and fumetreatment costs are neglected in the Our handling system can significantly boost your production capacity and effectiveness of your daily operation Our systems are a great way to transfer large amounts of coal over long distances They have the capability of significantly cutting down the cost of your production because they have very low power consumption rateCoal Handling Plant, Coal Handling system, Comparing coal handling system costs Power 01031996 Good maintenance practices and proactive planning are essential to ensure coal handling equipment performance, but a look at the entire cost of handling coal Get Price depreciation rates as perpanies Chat Online; News paring coal handling system costs

Global Coal Handling System Market Research

Coal handling system is an integral part of material flow and coal quality management of the plant There are various types of coal handling system including stackers, conveyors, feeders, reclaimers, ship loaders and unloaders and wagon tippler and loader12122018 The production cycle of opencast coal mines generally includes drilling, blasting, loading, hauling and coal preparation activities Individual optimization of these activities does not mean that the whole system is optimized This paper proposes a cost model considering all activities in mining cycle and systemwide approach to minimize the total mining cost of bench productionA systemwide approach to minimize the Economic benefits of the dry bottom ash handling system over the wet bottom ash handling system in a new 500MW2units pulverized coal thermal power plant in Korea were evaluatedEconomic Analysis of Dry Bottom Ash Handling

Ash Handling Options for CoalFired Power

Ash handling systems have experienced gradual changes since the 1970s, but the Kingston event triggered the US Environmental Protection (EPA) to create new regulations for ash handling that will Ash handling system are generally divided into three types fly ash handling system, bottom ash handling system and ash slurry disposal system Fly ash handling system: Fly ash is captured and removed from the flue gases by economiser, airpreheater and electrostatic precipitator (ESP) located at the outlet of the furnace and before the induced draftAsh Handling System in Thermal Coal 07052014 Requirement of Ash Handling System In Thermal Power Plant’s coal is generally used as fuel and hence the ash is produced as the byproduct of Combustion Ash generated in power plant is about 30 40% of total coal consumption and hence the system is required to handle Ash for its proper utilization or disposalAsh Handling System of a Thermal Power Plant