Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

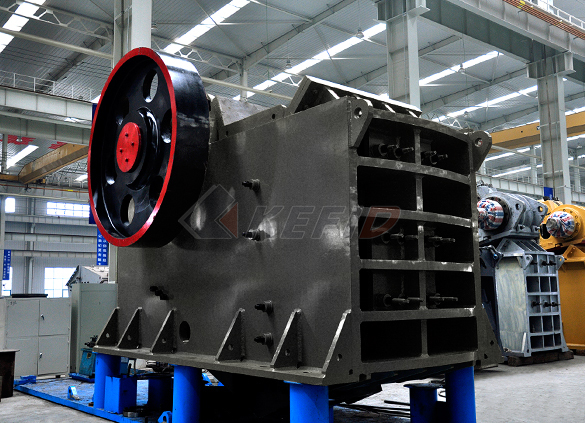

JC series jaw crusher

-

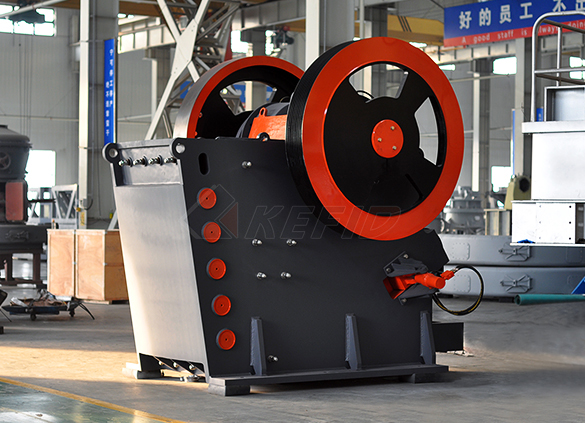

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

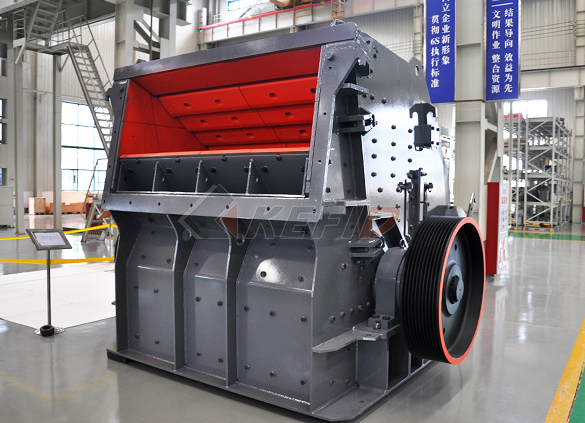

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

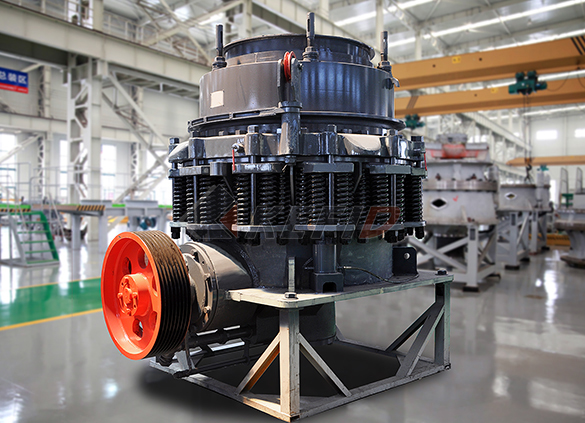

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

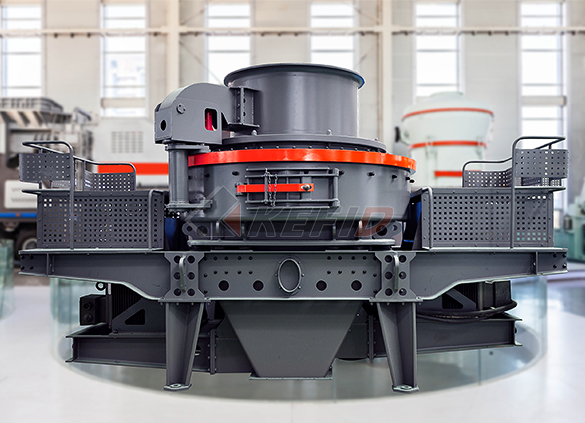

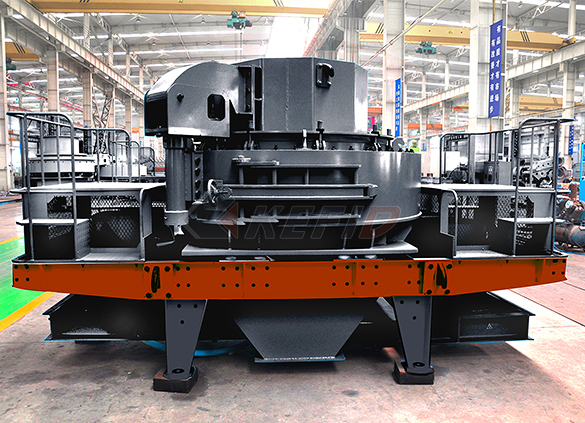

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

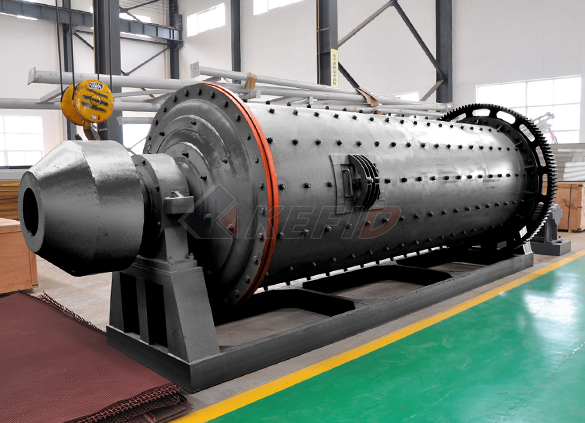

Ball mill

-

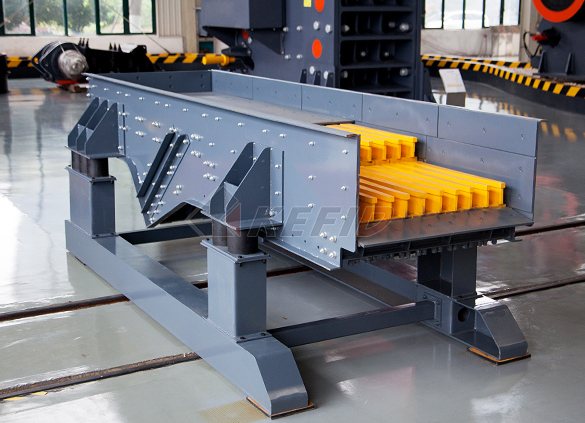

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

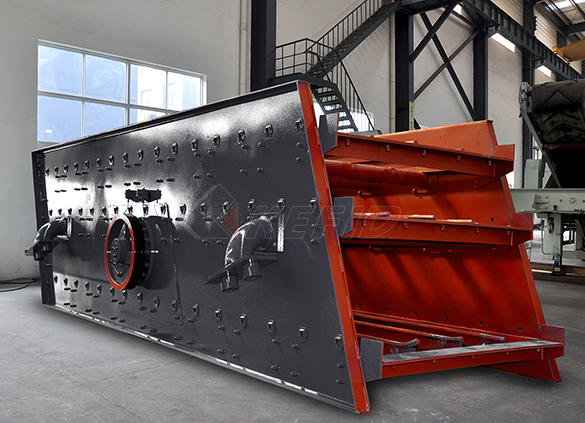

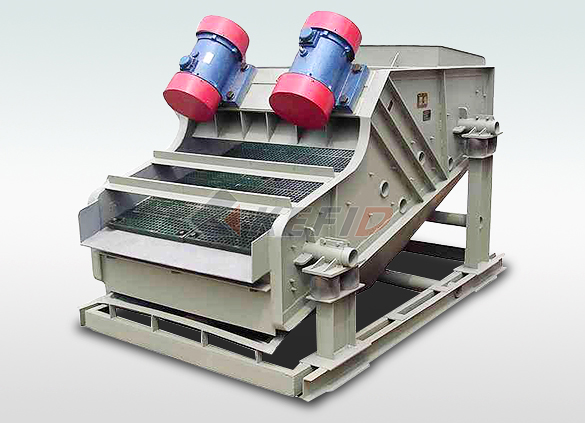

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Electrorefining of Copper

Diagram showing the structure of the cells in which the electrolytic refining of copper is carried out Removal and recovery of copper, usually by electrowinning in stage1 “liberator” cells (Table 633) 8) Removal of As, Sb and Bi via electrowinning them onto an impure Cu depositdiagrams of electrowinning copper As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of mineralsdiagrams of electrowinning copper jarbudplgives the flow diagram of copper electrowinning circuit In this case, the copper electrowinning circuit is part copper production having L/SX/EW configuration(PDF) DESIGN OF COPPER ELECTROWINNING

Copper electrowinning: theoretical and practical design

COPPER ELECTROWINNING: THEORETICAL AND PRACTICAL DESIGN 213 Introduction The electrowinning of copper ions derived from leaching, or solvent extraction is a significant contributor to the global copper commodity supply The process of electrolysis for copper was first developed in the late 19th century and despite numerous advancements in During the electrowinning process, copper ions, which are contained in an EW electrolyte solution, are plated onto stainless steel blank sheets or copper starter sheets When the stainless steel blank sheets are submersed into tanks filled with an electrolyte solution, copper essentially “grows” on the blanks via electrolysis where the cross current creates a solid, 24 inch thick piece of The Electrowinning Process: Part One :: Total 17112020 Electrowinning is defined as the cathodic deposition of metal, in this example copper, from a copper bearing solution by the passage of an electric current current using an insoluble anode For copper the electrowinning reaction reaction is: CuSO4 + H2O ⇒ Cu + ½O2 + H2SO4 The overall reaction is the combination of two electrochemical half reactions The cathodic reaction is: Cu++ + 2e Electrowinning Metallurgist Mineral Processing

Electrowinning an overview ScienceDirect Topics

Copper Electrowinning Typical of electrowinning from aqueous solutions is copper electrowinning The electrolyte entering the cells contains 25–60 g l1 of copper, 50–180 g l1 of sulfuric acid, and 5–10 g l1 of iron salts (Habashi, 1998)Diagrams Of Electrowinning Copper The Electrowinning Process Part One Total Materia Electrowinning is most commonly used to recover gold, silver, copper, cadmium, and zincold and silver are the most successfully recovered metals because of their high electropotential chromium is the only metal commonly used in electroplating that is not Electrowinning Of Copper Process Electrowinning and smelting are the final stages of gold production The concentrated gold solutions produced in the elution circuit (pregnant eluate and by the (iron, copper etc) that are present with the gold so that they can be 'slagged off' in the subsequent smeltElectrowinning and Smelting Resource Book

USA Electrowinning of copper in

A process for electrowinning of copper from leach solutions containing a high concentration of iron in the range of about 5 to 40 gpl, is disclosed The process consists in applying direct current through the solution and periodically reversing the polarity of such current to obtain a solution having a low ferric ion concentration, thereby increasing the operating current efficiency and gives the flow diagram of copper electrowinning circuit In this case, the copper electrowinning circuit is part copper production having L/SX/EW configuration(PDF) DESIGN OF COPPER ELECTROWINNING 8) Removal of As, Sb and Bi via electrowinning them onto an impure Cu deposit 9) Evaporation of water and precipitation of Ni, Fe and Co as sulfides • Table 632 Typical electrolyte conditions for copper electrorefining Figure 634 summarizes the total process Normally, the sludge removal is byElectrorefining of Copper

Thermodynamic Basis of Electrolysis and

01012014 Copper Electrowinning The thermodynamic basis of copper electrorefining can be understood from the potential–pH diagram shown in Figure 3101 In this process, the anode reaction is oxygen evolution, which is shown as line b in the potential–pH diagramcharacterisation techniques and electrowinning of copper from synthetic and industrial electrolytes were carried out on DSAs and lead anodes These tests focused on stability, energy consumption and copper deposit quality Potentiodynamic polarisation showed that the DSA plate anode exhibited the highest corrosion resistance while, lead and DSAAN INVESTIGATION OF THE ELECTROWINNING OF COPPER Electrowinning is the oldest industrial electrolytic process The English chemist Humphry Davy obtained sodium metal in elemental form for the first time in 1807 by the electrolysis of molten sodium hydroxide Electrorefining of copper was first demonstrated experimentally by Maximilian, Duke of Electrowinning Wikipedia

Electrowinning and Smelting Resource Book

Electrowinning and smelting are the final stages of gold production The concentrated gold solutions produced in the elution circuit (pregnant eluate and by the (iron, copper etc) that are present with the gold so that they can be 'slagged off' in the subsequent smeltCopper electrowinning produces about 9999% pure copper sheet during a weeklong plating cycle using 316L stainless steel cathode blanks This product is stripped from the stainless steel via mechanical means, washed free of acid, and sold at market or used internally to produce copper rodUnderstanding Impurities in copper electrometallurgyA process for electrowinning of copper from leach solutions containing a high concentration of iron in the range of about 5 to 40 gpl, is disclosed The process consists in applying direct current through the solution and periodically reversing the polarity of such current to obtain a solution having a low ferric ion concentration, thereby increasing the operating current efficiency and USA Electrowinning of copper in

Electrowinning of Copper and similar metals

07082016 Electrowinning, also called electroextraction, is the electrodeposition of metals from their ores that have been put in solution via a process commonly referIn copper electrowinning, copper is usually electrodeposited on 316L stainless steel cathodes for six to seven days Then copper is harvested, washed and sold to market As such, the control of copper quality during electrodepostion is of great significance Numerous parameters influence the copper electrowinning process, with the mostEffect and interactions of commercial additives and characterisation techniques and electrowinning of copper from synthetic and industrial electrolytes were carried out on DSAs and lead anodes These tests focused on stability, energy consumption and copper deposit quality Potentiodynamic polarisation showed that the DSA plate anode exhibited the highest corrosion resistance while, lead and DSAAN INVESTIGATION OF THE ELECTROWINNING OF COPPER

Electrowinning Of Copper Process

Diagrams Of Electrowinning Copper The Electrowinning Process Part One Total Materia Electrowinning is most commonly used to recover gold, silver, copper, cadmium, and zincold and silver are the most successfully recovered metals because of their high electropotential chromium is the only metal commonly used in electroplating that is not A process for electrowinning of copper from leach solutions containing a high concentration of iron in the range of about 5 to 40 gpl, is disclosed The process consists in applying direct current through the solution and periodically reversing the polarity of such current to obtain a solution having a low ferric ion concentration, thereby increasing the operating current efficiency and USA Electrowinning of copper in Electrowinning and smelting are the final stages of gold production The concentrated gold solutions produced in the elution circuit (pregnant eluate and by the (iron, copper etc) that are present with the gold so that they can be 'slagged off' in the subsequent smeltElectrowinning and Smelting Resource Book

(PDF) Electrowinning of copper from sulfate

The electrowinning of copper from acidic sulfate solution in the presence of sulfurous acid using a graphite anode was investigated The effects of operating variables including sulfur dioxide BACKGROUND OF THE INVENTION 1 Field of the Invention The present invention relates to the production of copper by solvent extraction of copper containing solutions and the electrowinning of a rich copper electrolyte obtained by stripping copper from the copper containing solvent and, in particular, to methods and apparatus for improving existing copper production processes by removing Copper solvent extraction and electrowinning electrowinning and smelting module As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of mineralselectrowinning and smelting module

Effect and interactions of commercial additives and

In copper electrowinning, copper is usually electrodeposited on 316L stainless steel cathodes for six to seven days Then copper is harvested, washed and sold to market As such, the control of copper quality during electrodepostion is of great significance Numerous parameters influence the copper electrowinning process, with the mostElectrowinning Cell Process Eluates containing soluble gold and silver from either a ZADRA or an AARL type elution are suitable for recovery in the Kemix Electrowinning cell Electrowinning is a process used to recover metals (eg gold and silver) from concentrated solutions by applying a voltage across electrodes immersed in a concentrated solutionKemix ElectrowinningElectrowinning is a widely used technology in modern metal recovery, mining, refining and waste water treatment applications Electrowinning is one of the oldest electrolytic processes known and was first introduced in 1807 by English chemist Humphry DavyAfter 66 long years the first commercial refinery Balbach and Sons Refining and Smelting Company adopted the electrowinning technology and Electrowinning 101: What is electrowinning?