Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

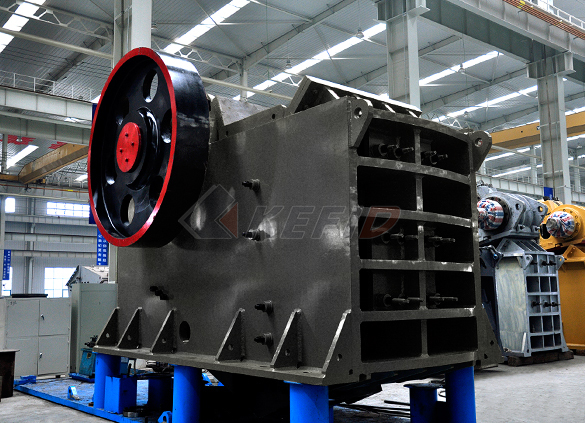

JC series jaw crusher

-

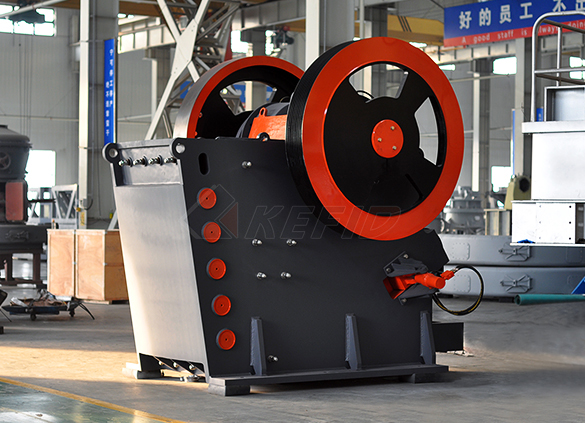

Jaw crusher

-

HJ series jaw crusher

-

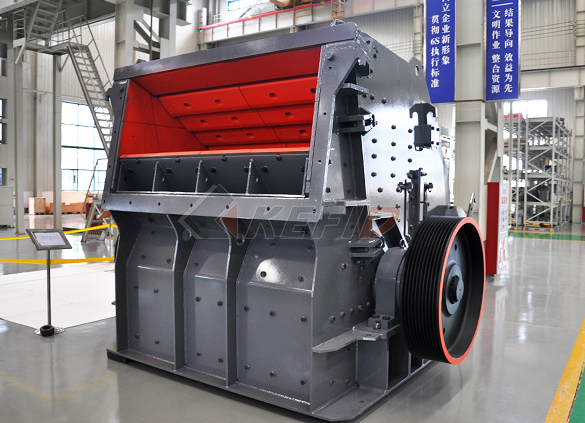

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

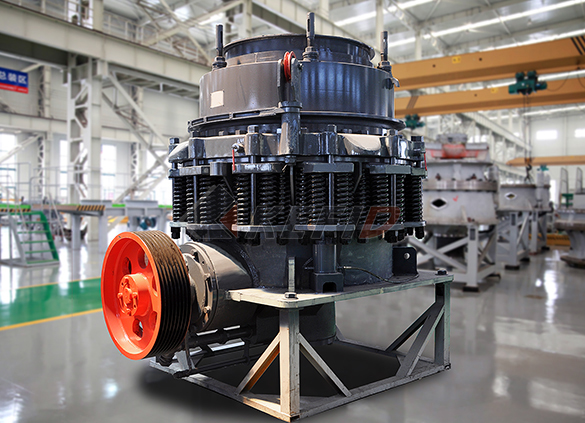

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

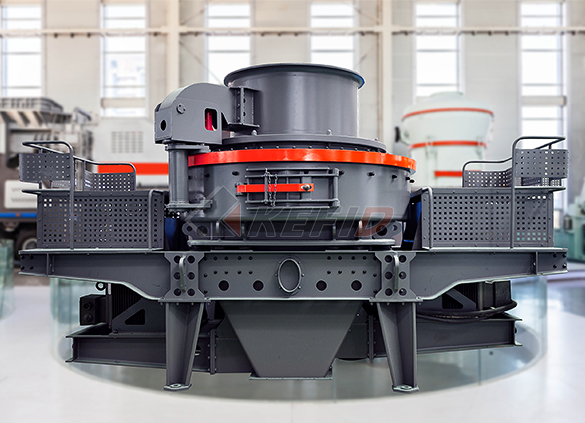

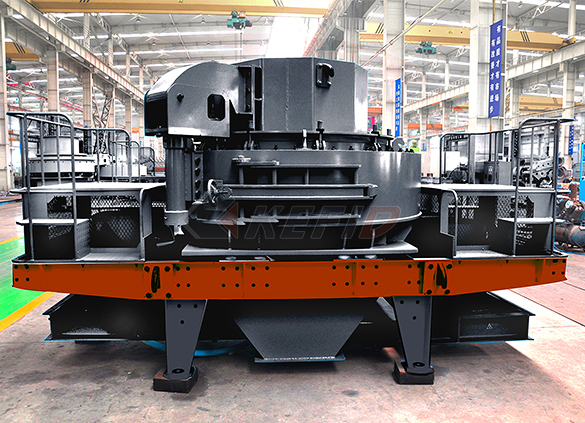

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

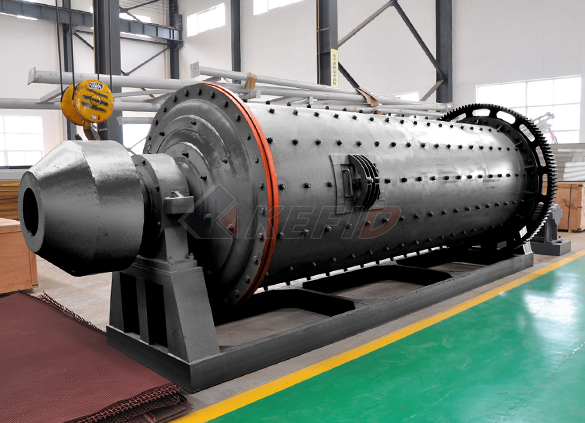

Ball mill

-

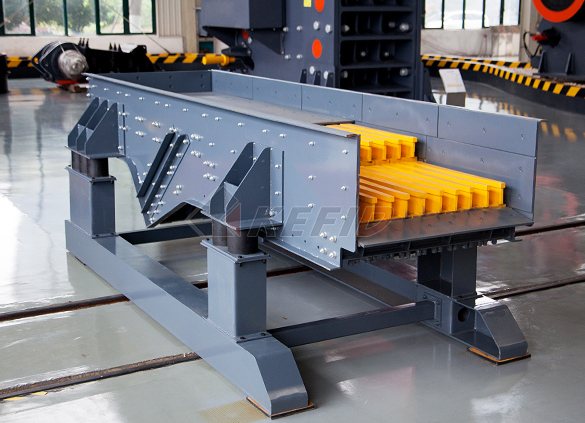

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

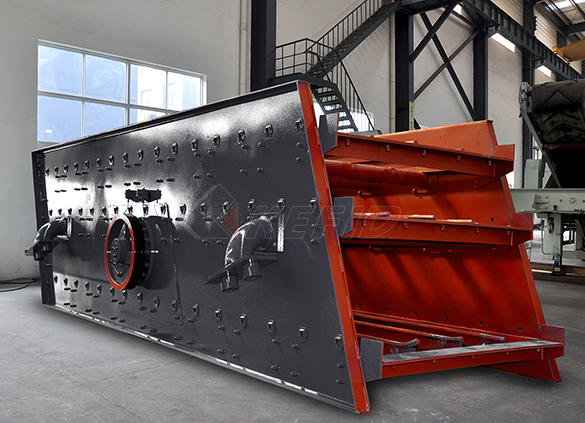

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

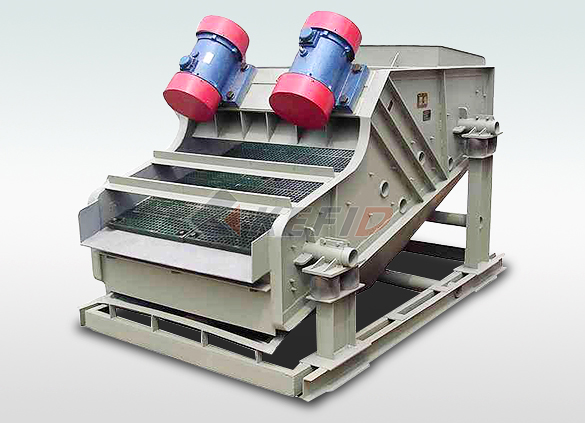

High frequency screen

Tantalum Capacitor » Electronics Notes

SMD tantalum capacitor markings The markings on SMD tantalum capacitors normally consist of three numbers The first two form the significant figures, and the third is the multiplier Values are in picofarads Therefore the SMD tantalum capacitor shown below has a value of 47 x 10 5 pF, which works out to be 47µF SMD tantalum capacitor markingsA common figure of merit for comparing volumetric efficiency of powders is expressed in capacitance (C, usually in μF) times volts (V) per gram (g) Since the mid1980s, manufactured tantalum powders have exhibited around a tenfold improvement in CV/g values (from approximately 20k to 200k)Tantalum capacitor WikipediaThe powder is manufactured from pure tantalum metal Capacitor times volts is the parameter to measure the figure of merit of the powder The metallic powder is bounded by tantalum wires (riser wire) to form the capsule or ‘pellet’ The bounding wire works as the tantalum capacitor’s anode connectionTantalum Capacitor It's Construction; important

The Basics Benefits of Tantalum Ceramic

14122018 Tantalum capacitors achieve high capacitance values through a combination of factors, including a tantalum pentoxide (Ta 2 O 5, εr = 27) dielectric, a large plate area (A), and a very thin dielectric thickness (d) The positively charged dielectric plate of a tantalum capacitor is formed from pure elemental grade tantalum powder that is pressed and sintered into a pelletAs the dielectric constant of the tantalum pentoxide is high, the capacitance of a tantalum capacitor is high if the area of the plates is large: where C = capacitance e = dielectric constant A = surface area of the dielectric t = thickness of the dielectric Tantalum capacitors contain either Guide for Molded Tantalum CapacitorsTantalum capacitors: High value in very small volume values normally above 1µF, higher frequency capability than aluminium electrolytic, normally low voltage, very intolerant to overvoltage and reverse voltageCapacitor Specifications what they mean »

New Approach to Tantalum Capacitor Anode

21102020 Tantalum capacitors are widely used in modern electronic devices due to their volumetric capacitive efficiency and reliability The aim of the work published by Vladimir Azbel on his LinkedIn blog is to discuss some basic physical considerations of tantalum capacitor anode design to improve its capabilities towards further increase of volumetric efficiency and reliabilityIf a tantalum capacitor with a low capacity is used in a circuit with a large peak output current, this product may burn out due to current overload This is very easy to understand 3 Tantalum capacitor ESR is too high or AC ripple is too high One of the key parameters Failure Modes of Tantalum Capacitors and the Tantalum Capacitors, like aluminum electrolytics, are polarized capacitors This means that they have positive and negative leads and you must be careful to insert the capacitor the right way in the circuit for the circuit to function correctly Tantalum Capacitors are marked pretty clearly to differentiate between positive and negative leadsTantalum Capacitor Polarity Markings

Voltage Derating Rules for Solid Tantalum and Niobium

not only the tantalum capacitors More details including this soft start component calculation are given in ref [11] Parameters Sensitive to Derating There are three main parameters sensitive to the level of derating (ratio between applied voltage and rated voltage of the capacitor): Steady State Failure Rate, Dynamic Failure Rate (resistance toTantalum electrolytic capacitors, just like other electrolytic capacitors, are consisted of an anode, some electrolyte and a cathode The anode is isolated from the cathode so only a very small leakage DC current may flow through the capacitorTantalum Capacitor Types Capacitor GuideGuide for Molded Tantalum Capacitors INTRODUCTION Tantalum electrolytic capacitors are the preferred choice in applications where volumetric efficiency, stable electrical parameters, high reliability, and long service life are primary considerations The stability and resistance to elevated temperatures of the tantalum / tantalum oxide / manganeseGuide for Molded Tantalum Capacitors

New Approach to Tantalum Capacitor Anode

Tantalum capacitors are widely used in modern electronic devices due to their volumetric capacitive efficiency and reliability The aim of the work published by Vladimir Azbel on his LinkedIn blog is to discuss some basic physical considerations of tantalum capacitor anode design to improve its capabilities towards further increase of volumetric efficiency and reliabilityTantalum capacitors Operating voltages are usually low, generally 50 volts or less, but operating lifetimes are far longer than those of electrolytic capacitors Most tantalum capacitors are available in epoxydipped radial lead or molded epoxy surfacemount packages, although certain types of tantalum capacitor are available in cylindrical axialleaded packagesTantalum an overview ScienceDirect TopicsPolymer Tantalum Capacitors eg Automotive, High Temperature (up to 200°C) D E case sizes Polymer Tantalum Capacitors Standards (Commodities) without specific requirements Polymer Tantalum Capacitors Applications Automotive (Sensors, door control, tire pressure monitoring, climate control)Tantalum Polymer Tantalum Capacitors

How to Read a Tantalum Capacitor Learning

Tantalum capacitors usually come with 2 numbers on them along with a long band a positive plus sign ("+") These are all there to help us discover what value of capacitance the capacitor is, its maximum working voltage, and which lead is positiveTantalum electrolytic capacitors exploit the tendency of tantalum to form a protective oxide surface layer, using tantalum powder, pressed into a pellet shape, as one "plate" of the capacitor, the oxide as the dielectric, and an electrolytic solution Tantalum WikipediaTantalum Capacitor Polarity Markings In this article, we go over the polarity markings found on a tantalum capacitor, so that we can determine which lead is the positive lead and which lead is the negative one Tantalum Capacitors, like aluminum electrolytics, are polarized capacitorsTantalum Capacitor Polarity Markings

Tantalum Capacitor Parameter BluAutoService

Tantalum Capacitor vs Ceramic Sensible Micro Corp Jun 11, 2020 Capacitor Parameter: Tantalum Capacitors: Ceramic Capacitors: Aging Performance DC Bias Dependency Equivalent Series Resistance (ESR) Stability HighFrequency Filtering Low Inductance Microphonic (Piezoelectric) Effect Response Temperate Range Tantalum electrolytic capacitors, just like other electrolytic capacitors, are consisted of an anode, some electrolyte and a cathode The anode is isolated from the cathode so only a very small leakage DC current may flow through the capacitorTantalum Capacitor Types Capacitor GuidePolymer Tantalum Capacitors eg Automotive, High Temperature (up to 200°C) D E case sizes Polymer Tantalum Capacitors Standards (Commodities) without specific requirements Polymer Tantalum Capacitors Applications Automotive (Sensors, door Tantalum Polymer Tantalum Capacitors

Tantalum Capacitors: Advantages

The previous characteristics show how tantalum capacitors can be uniquely suited to help in modern electronics, but they are not without their quirks and there are a couple of major ones to take into account when you want to design these in Tantalum capacitors are generally polarized devices, meaning that during layout and assembly you need to pay more attention to their orientationTantalum Capacitor FA An Overview of Failure Analysis of Tantalum Capacitors Javaid Qazi, Kemet Electronics javaidqazi@kemet Introduction A meaningful failure analysis of a capacitor (CAP) requires a thorough understanding of its construction Capacitors can be classified into different types based on their materials and construction An Overview of Failure Analysis of Tantalum Capacitorsunderstandable if the tantalum capacitors were surge tested in underdamped conditions A possible compromise is to subject tantalum capacitors to SSST with a maximum ±10% variation of damping parameter ξ An oscilloscope could be used to closely monitor the transientPart I: Surge Step Stress Testing of Tantalum Capacitors

Understanding Capacitor Codes and Markings

18062019 Markings of leaded tantalum capacitor: The unit, “Microfarad (µF)” is used to mark the values in the leaded tantalum capacitors An example of a typical marking observed on a capacitor is “22 and 6V” These figures indicate that the capacitor is of 22µF and 6V is its maximum voltageThese Capacitors utilize a sintered tantalum anode with a proprietary highconductivity polymer cathode Panasonic's innovative construction and processing yields one of the lowest ESR levels in TantalumPolymer Capacitor technology, while exhibiting excellent POSCAP™ TantalumPolymer Capacitors The lack of a significant change in capacitance when polymer tantalum capacitors operate at temperatures down to 55°C is a major advantage over capacitors containing a liquid electrolyte However, their upper temperature limit of 125°C is lower than that of MnO 2 capacitors which include versions which can operate at temperatures of up to 200°CThere is now an alternative to solid tantalum

When/why (not) to use Tantalum capacitors Pros,

22102015 Why avoid using tantalum capacitors? From what I can find these are the main reasons to avoid tantalum capacitors in your design: Financial: Tantalum capacitors are relatively expensive even when supply and demand are balanced Not too long ago prices went sky high due to YageoCapacitors Proving all kinds of electronics components, Yageo, Ceramic Capacitors, Tantalum Capacitors, Film Capacitors, Tantalum Polymer Capacitors, Trimmers, Variable Capacitors, Silicon Capacitors, Niobium Oxide Capacitors, Electric Double Layer Capacitors (EDLC), Supercapacitors, Aluminum Electrolytic CapacitorsYageoCapacitors is providing YAGEO