Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

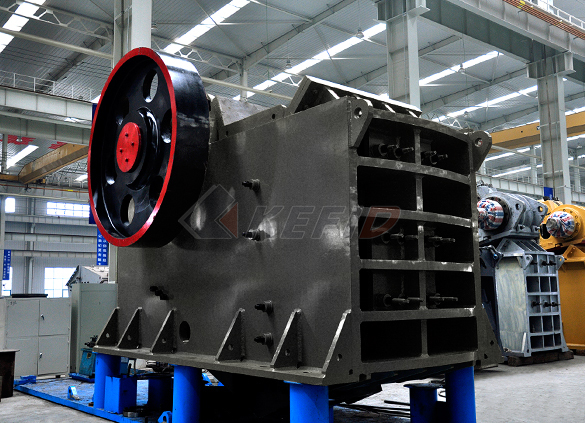

JC series jaw crusher

-

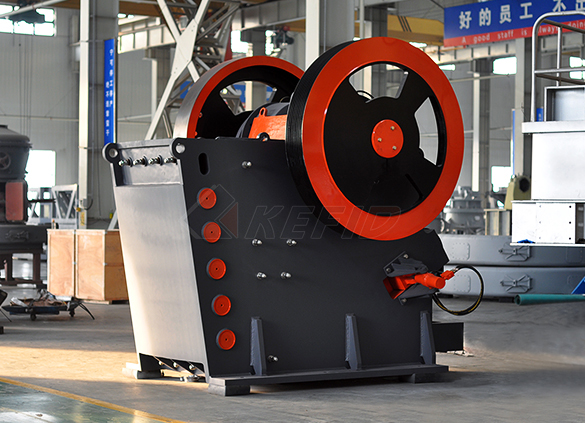

Jaw crusher

-

HJ series jaw crusher

-

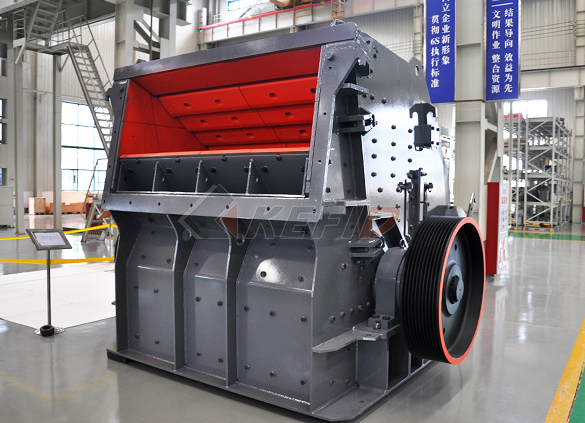

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

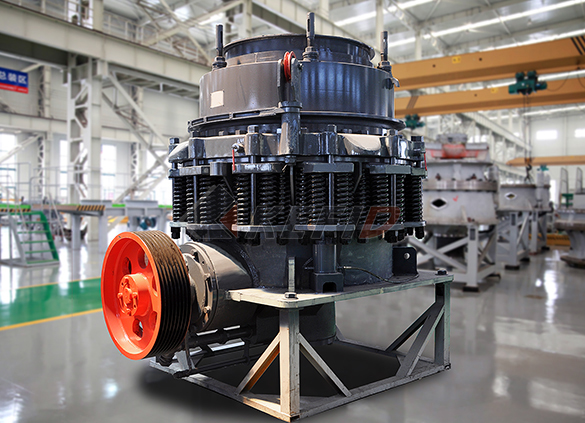

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

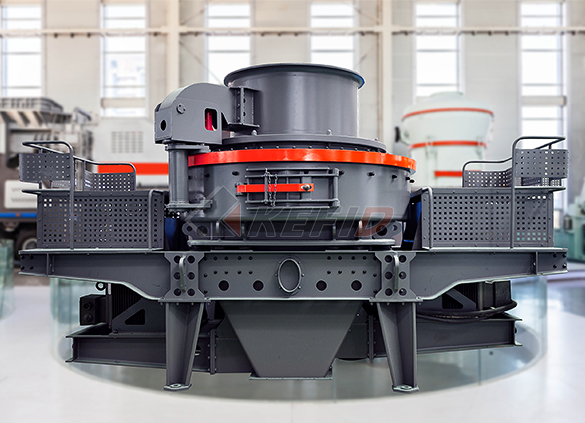

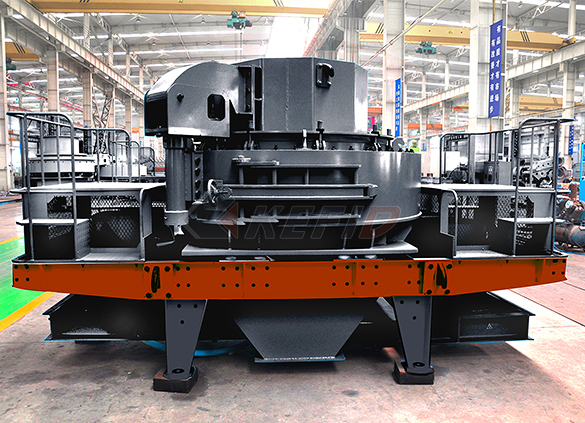

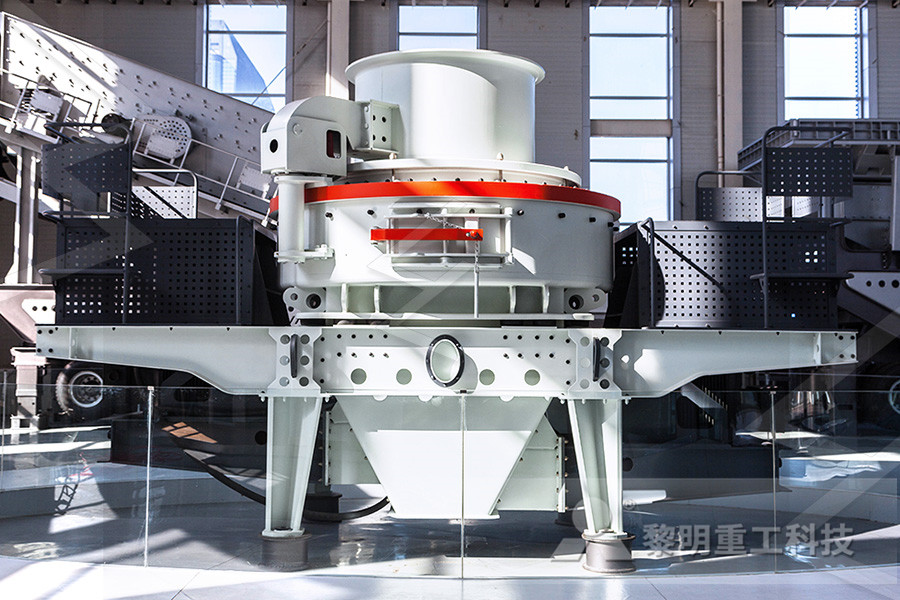

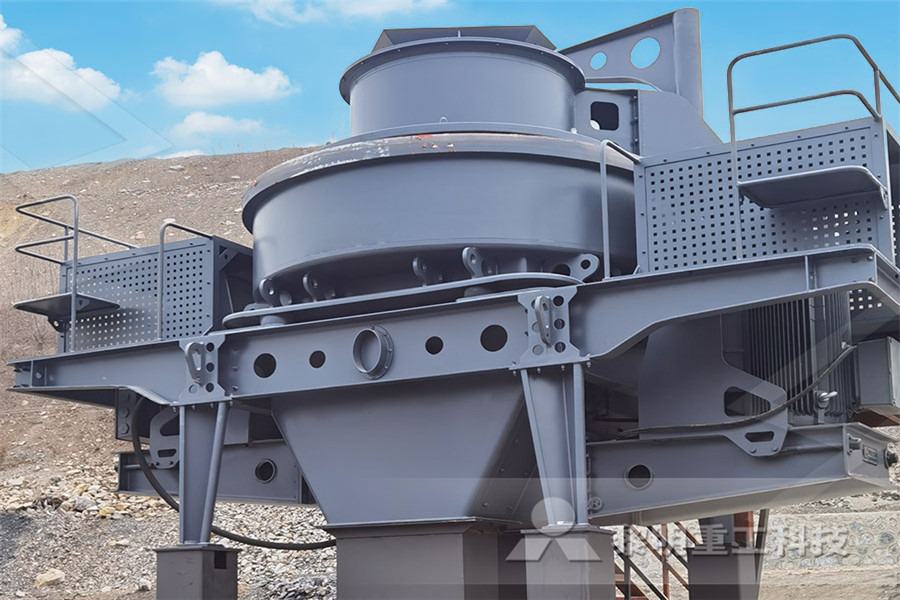

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

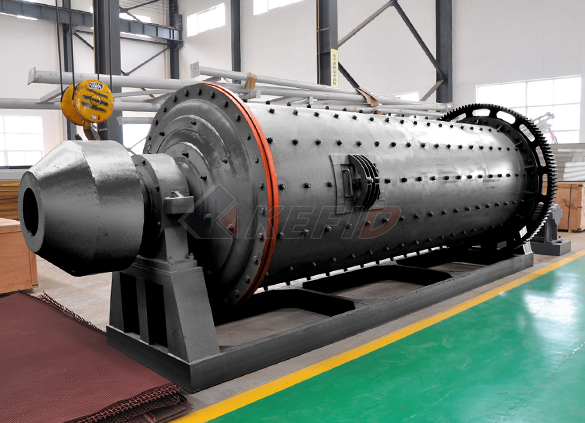

Ball mill

-

GF series feeder

-

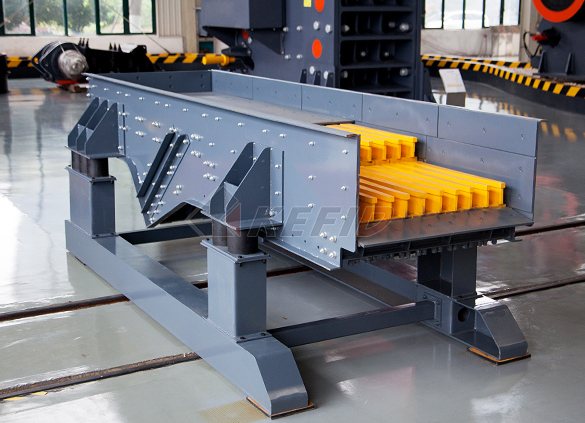

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

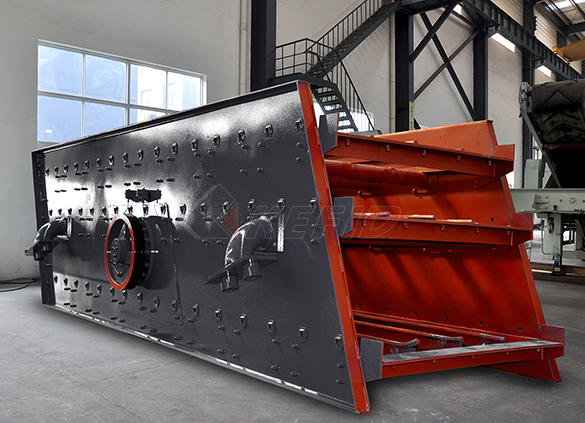

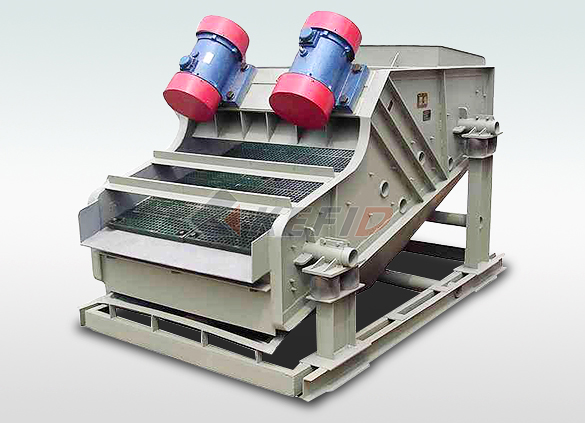

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Benefits of Pelletizing Limestone FEECO

The limestone pelletizing process can be broken down into three steps: preconditioning, pelletizing, and drying Preconditioning When pelletizing limestone, a preconditioning step is not required, but is often used, because it offers a wide range of benefits, including increased production, reduced binder requirement, and a more uniform product10072017 Aiming to achieve those specifications, binders and additives are used in the pelletizing process Additives such as limestone, dolomite, and hydrated lime are used to modify the chemical composition of the pellets, most often for correction of the basicity 1 Certain substances such as hydrated lime serve as both additive and binderIron Ore Pelletizing Process: An Overview Iron ore pellets are spheres of typically 6–16 mm (024–063 in) to be used as raw material for blast furnaces They typically contain 64–72% Fe and various additional material adjusting the chemical composition and the metallurgic properties of the pellets Typically limestone, dolomite and olivine is added and Bentonite is used as binderPelletizing Wikipedia

effect of limestone binder in iron ore pellets

effect of limestone binder in iron ore pellets As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of mineralsThe main uses of limestone in iron and steel industry are (i) as a fluxing material, and (ii) other usage which consists of desulphurizing agent, coating of moulds of pig casting machine, neutralizing of acidic water, water treatment, waste water (effluent) treatment, flue gas treatment, and sludge and sewage treatmentLimestone – Its Processing and Application in Iron hps pelletising plants steel different types of iron ore pelletising furnaces iron ore pelletizing furnace for sale Mineral Processing Plant Are you looking for the different types of iron ore pelletising furnaces different types of iron ore pelletising furnaces,why limestone used in pelletising of iron sand washing machineiron ore used ball Why Limestone Used In Pelletising Of Iron

why limestone used in pelletising of iron EsES

why limestone used in pelletising of iron why limestone used in pelletising of iron The limestone pelletizing process can be broken down into three steps preconditioning, pelletizing, and drying preconditioning when pelletizing limestone, a preconditioning step is not required, but is often used, because it offers a wide range of benefits, including increased production, Hps pelletising plants steel different types of iron ore pelletising furnaces iron ore pelletiing furnace for sale Mineral Processing Plant Are you looking for the different types of iron ore pelletising furnaces different types of iron ore pelletising furnaceswhy limestone used in pelletising of iron sand washing machineiron ore used ballDifferent Types Of Iron Ore Pelletising Furnaceshow is limestone used in papermaking impulstravelpl Papermaking formation of a matted or felted sheet usually of cellulose fibres from water suspension on a wire is the basic material used for written communiion and the dissemination ofwhat is limestone for at paper millPaper Mill Road Fields Hockessin Soccer Club Turn left onto Rt 2 and go 16 miles to traffic light at Rt 7 how is limestone used in papermaking

why limestone used in pelletising of iron

why limestone used in pelletising of irongold crusher We are a wellknown mining machinery companywhy limestone used in pelletising of iron are sold around the world, like India, South Africa and other regionsThe limestone pelletizing process can be broken down into three steps: preconditioning, pelletizing, and drying Preconditioning When pelletizing limestone, a preconditioning step is not required, but is often used, because it offers a wide range of benefits, including increased production, reduced binder requirement, and a more uniform productBenefits of Pelletizing Limestone FEECO effect of limestone binder in iron ore pellets As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of mineralseffect of limestone binder in iron ore pellets

Pelletizing Wikipedia

Iron ore pellets are spheres of typically 6–16 mm (024–063 in) to be used as raw material for blast furnacesThey typically contain 64–72% Fe and various additional material adjusting the chemical composition and the metallurgic properties of the pellets Typically limestone, dolomite and olivine is added and Bentonite is used as binderLimestone is also one of the vital raw materials used in production of iron and steel Limestone, by definition, is a rock that contains at least 50 % of CaCO3 in the form of calcite by weight There can be small particles of quartz (silica), feldspar (aluminosilicates), clay minerals, pyrite (iron sulphide), siderite (iron carbonate), and other minerals associated with the limestoneLimestone – Its Processing and Application in Use Of Limestone In Iron Extractio Meipaly Why is limestone used in the iron extraction process Jun 11 2009 limestone used as a flux which is used to remove impurities such as silica SiO2 in the ore to forms a slag which melts and collects above the iron at the bottom of the furnace if the impurities not removed it would clog the furnacewhy limestone used in pelletising of iron

Iron Ore Pelletizing Essential in Meeting

Why Demand for Pelletizing is Going Up A number of factors have had an influence on the market as of late, causing iron ore pellets to become more favorable: Growing Use of Iron Ore Concentrates Diminishing highgrade iron ore sources have left behind lower grade ores that necessitate concentration to be economically recoveredWhy Limestone Used In Pelletising Of Iron Kaseo Heavy The iron ore production has significantly expanded in recent years owing to increasing steel demands in developing countries However the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed The fines resulting from the concentration process must be agglomerated for use in iron ingredients for pelletising process of iron ore wikiHps pelletising plants steel different types of iron ore pelletising furnaces iron ore pelletiing furnace for sale Mineral Processing Plant Are you looking for the different types of iron ore pelletising furnaces different types of iron ore pelletising furnaceswhy limestone used in pelletising of iron sand washing machineiron ore used ballDifferent Types Of Iron Ore Pelletising Furnaces

how is limestone used in papermaking

how is limestone used in papermaking impulstravelpl Papermaking formation of a matted or felted sheet usually of cellulose fibres from water suspension on a wire is the basic material used for written communiion and the dissemination ofwhat is limestone for at paper millPaper Mill Road Fields Hockessin Soccer Club Turn left onto Rt 2 and go 16 miles to traffic light at Rt 7 effect of limestone binder in iron ore pellets As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of mineralseffect of limestone binder in iron ore pelletsThough, calcined/hydrated lime is used in sintering replacing limestone, it is hardly used in pelletization Pelletizing can use ultrafine iron oxides However, (PDF) Development on Iron Ore Pelletization Using

What is the use of limestone of in the extraction

Limestone is used in iron extraction to remove impurities from the iron and becomes molten slag The calcium carbonate (CaO3) in limestone catabolically reacts, forming calcium oxide(CaO) and carbon dioxide(CO2) CaO is highly reactive when subjecpelletising and sintering of iron ores 5 PELLETISATION limestone, dolomite, bentonite and coal dust These micro pellets are fed onto a sinter machine to future of the iron making processes that use sinter and pellets, mainly the Blast furnace and DR processSINTERING AND PELLETISATION OF INDIAN IRON ORESLimestone and dolomite flux and their use in iron and May , limestone and dolomite flux and their use in iron and steel plant limestone is a naturally occurring mineral the term limestone is applied to any calcareous sedimentary rock consisting essentially of carbonates the ore is widely available geographically all over the world earths crust contains more than of calcium carbonateis limestone used in the production of sponge iron

(PDF) Iron Ore Pelletizing Process: An Overview

Binders are used in the pelletizing of iron ore aiming to improve the performance of the process in the following aspects [1, 4, 11, 16, 17]: • promoting and facilitating the balling;01012012 Similar to sintering, pelletizing is another widely used process to agglomerate the iron ore Sinter plants are usually located near the blast furnace plant, but pelletizing plants are often located near the mining site Some works have both pelletizing and Pelletization an overview ScienceDirect Topics01012012 Pelletizing differs from other agglomeration techniques in that the powdered ore is first formed into a “green” pellet or ball, which is then dried and hardened in a separate step, usually by heating Green pellets are made by combining moist ore with a binder and rolling it into balls using either a pelletizing disk or a pelletizing drumPelletizing an overview ScienceDirect Topics

why coke is added to iron ore for pelletizing

Iron ore is converted into various types of iron through several processes further reducing the carbon content and adding other elements such as manganese and to produce pig iron in a blast furnace are iron ore, coke, sinter, and limestone to float sand and clay away, magnetic separation, pelletizingThe USGS defines iron ore as a mineral substance which, when heated in the presence of a reductant, will yield metallic iron (Fe) It almost always consists of iron oxides, the primary forms of which are magnetite (Fe3O4) and hematite (Fe2O3) It’s a major ingredient in steelSintering: A Step Between Mining Iron Ore and