Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

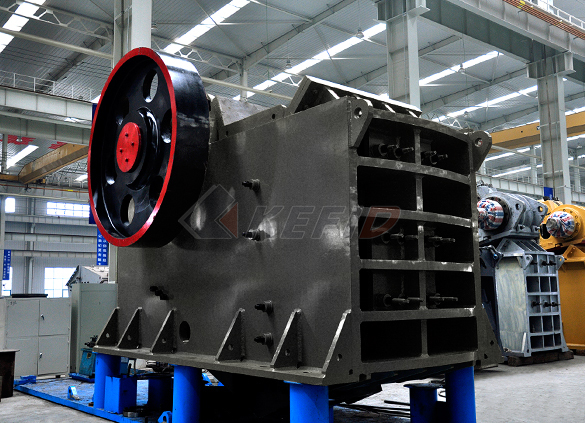

JC series jaw crusher

-

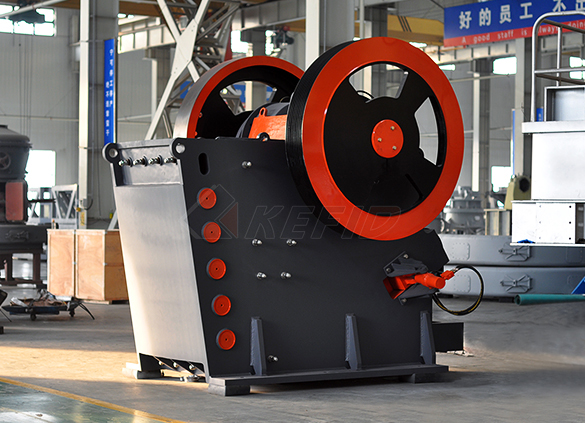

Jaw crusher

-

HJ series jaw crusher

-

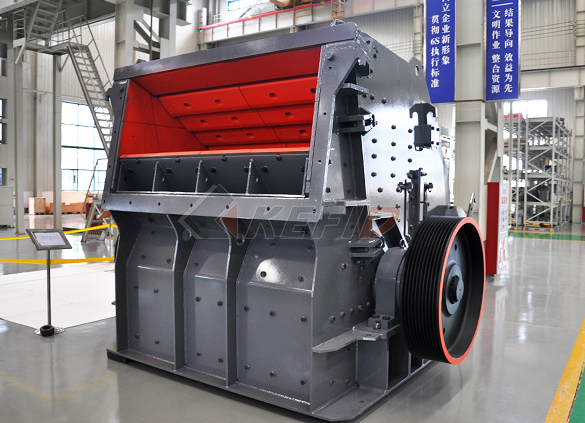

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

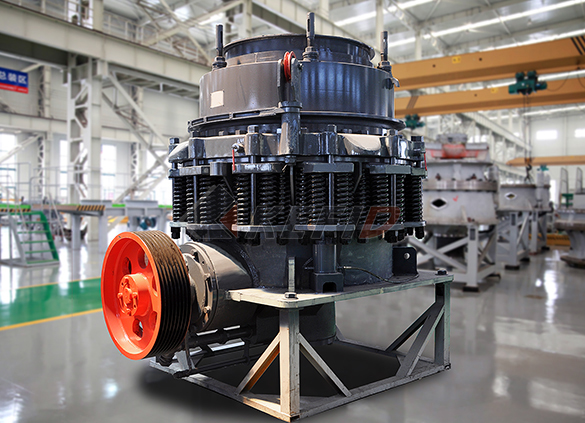

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

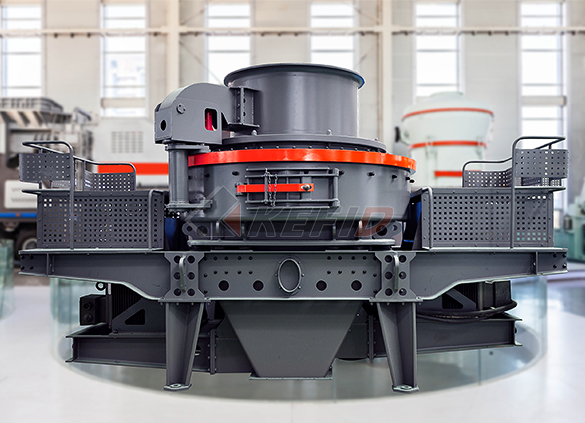

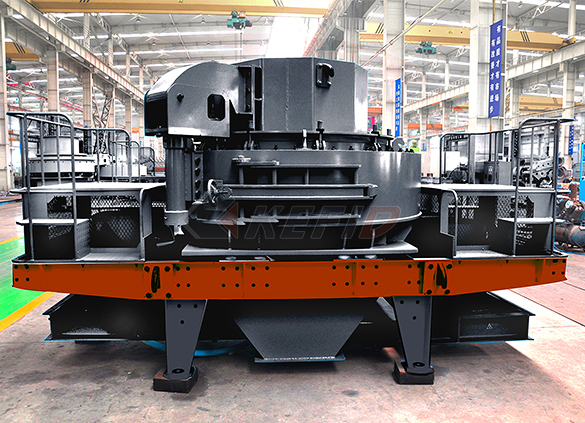

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

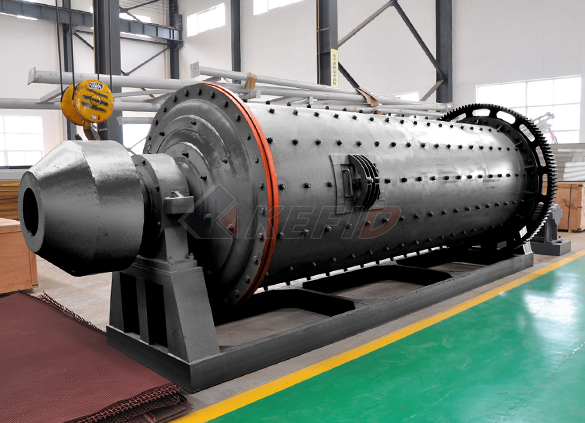

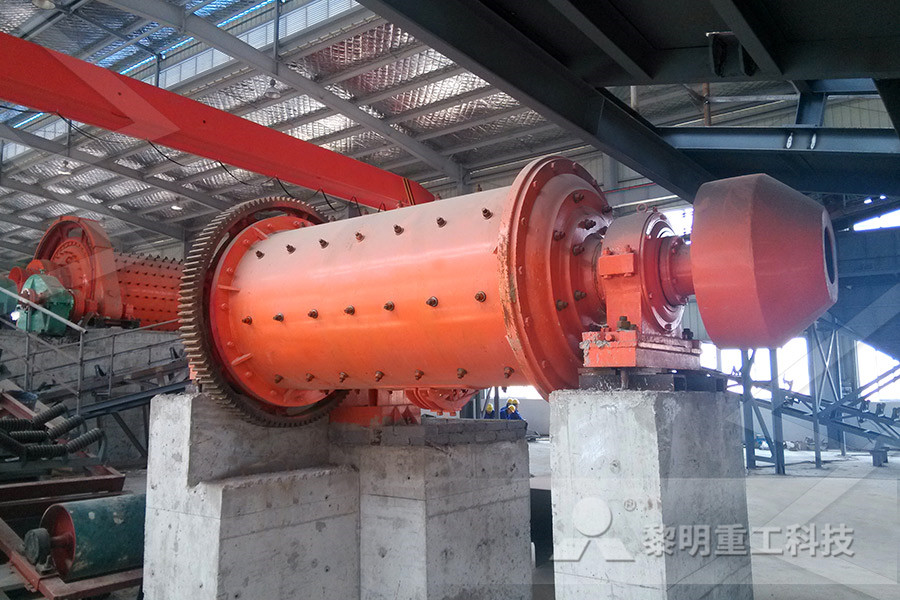

Ball mill

-

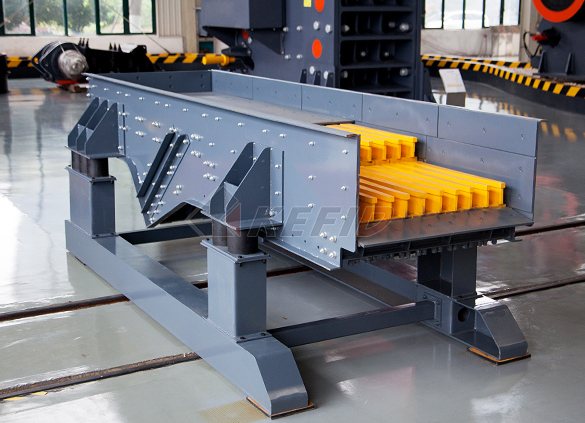

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

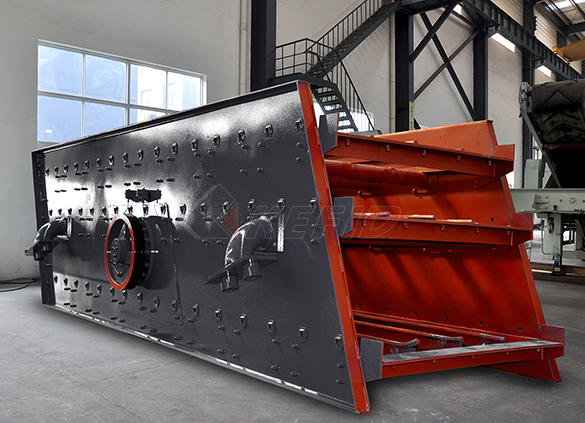

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

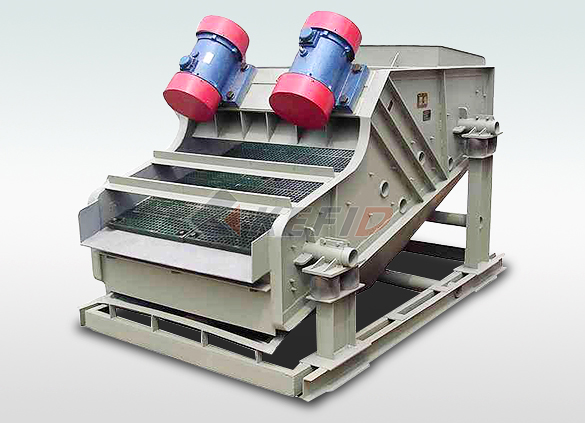

Electromagnetic vibrating feeder

-

High frequency screen

Ball Mill Critical Speed Mineral Processing

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell’s inside surface and no balls will fall from its position onto the shell The imagery below helps explain what goes on inside a mill as speed varies Use our online formula The mill speed is typically defined as the percent of the Theoretical Effect of Mill Speed on the Energy Input In this experiment the overall motion of the assembly of 62 balls of two different sizes was studied The mill was rotated at 50, 62, 75 and 90% of the critical speed Six lifter bars of rectangular crosssection were used at equal spacing The overall motion of the balls at the end of five revolutions is shown in Figure 4 As can be seen from the Mill Critical Speed CalculationBall Mill Critical Speed Derivation Ball Mill Critical Speed A Ball Mill Critical Speed actually ball rod AG or SAG is the speed at which the centrifugal forces equal gravitational forces at the mill shells inside surface and no balls will fall from its position onto the shell The imagery below helps explain what goes on inside a mill as speed variesThery Of Critical Speed Of Ball Mill

Question On Critical Speed Of Ball Mill

The Critical Speed is used for the determination of ball mill ideal operating speed But for comparison rod mills would operate between 50 to 95 of the critical speed The faster the mill speed the greater the wear on the rods and linersMill Speed Critical Speed Mill Speed No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar rolling mill, its rotational speed is important to proper and efficient mill operation Too low a speed and little energy is imparted on the productMill Speed Critical Speed Paul O AbbeThe "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at the mill shell's inside surface This is the rotational speed where balls will not fall away from the mill's shell Result #1: This mill would need to spin at RPM to be at 100% critical speed : Mill Critical Speed

Thery Of Critical Speed Of Ball Mill

Ball Mill Critical Speed Derivation Ball Mill Critical Speed A Ball Mill Critical Speed actually ball rod AG or SAG is the speed at which the centrifugal forces equal gravitational forces at the mill shells inside surface and no balls will fall from its position onto the shell The imagery below helps explain what goes on inside a mill as speed varies20062015 https://911metallurgist/blog/ballmill Learn about Ball Mill Critical Speed and its effect on inner charge movements The effect of Ball Mill RPM sBall Mill Critical Speed Working Principle The Critical Speed is used for the determination of ball mill ideal operating speed But for comparison rod mills would operate between 50 to 95 of the critical speed The faster the mill speed the greater the wear on the rods and linersQuestion On Critical Speed Of Ball Mill

Mill Speed Critical Speed Paul O Abbe

Mill Speed Critical Speed Mill Speed No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar rolling mill, its rotational speed is important to proper and efficient mill operation Too low a speed and little energy is imparted on the productMill Speed Critical Speed Paul O Abbe Talk with the Experts at Paul O Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needscritical speed for a ballmill mayukhportfoliocoAt what speed will the mill have to be run if the 100 mm balls are replaced by 50 mm balls, all the other conditions remaining the same? Calculations: The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball For R = 1000 mm and r = 50 mm, n c = 307 rpm But the mill is operated at a speed of 15 rpmBall Mill Operating Speed Mechanical

Ball Mills Mine

This formula calculates the critical speed of any ball mill Most ball mills operate most efficiently between 65% and 75% of their critical speed Photo of a 10 Ft diameter by 32 Ft long ball mill in a Cement PlantA ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sinteringIt works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow cylindrical shell rotating aboutBall mill Wikipediaball mill critical speed calculation the height the ball raised is high now only the calculation formula on critical speed in theory is widely used,Matches 1 critical critical speed of ball mill pdf Hitz Shoes derivation for the critical speed of ball millcritical speed for a ballmill ecoleenricomaciasbe

derivation of critical speed in a ball mill pdf

ball mill equation derivation pdf Derivation of formula of ball mill ballmill,critical speed of ball mill,horizontal ball mill youtube derivation of formula of ball mill , jul , websitegoldenmill our products,such as crushers, sand makers , milling equipment and so on have already got the iso certificateth,formula for critical speed of a rotating mill youtube jan , critical speed of ball millBall Mill Critical Speed Derivation Ball Mill Critical Speed A Ball Mill Critical Speed actually ball rod AG or SAG is the speed at which the centrifugal forces equal gravitational forces at the mill shells inside surface and no balls will fall from its position onto the shell The imagery below helps explain what goes on inside a mill as speed variesThery Of Critical Speed Of Ball MillA ball mill is a type of grinder used to grind or blend materials for use in mineral dressing Critical speed can be understood as that speed after which the steel balls that are responsible for the grinding of particles start rotating along thecalculating critical speed in a ball mill uae

Mill Speed Critical Speed Paul O Abbe

Mill Speed Critical Speed Mill Speed No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar rolling mill, its rotational speed is important to proper and efficient mill operation Too low a speed and little energy is imparted on the productMill Critical Speed Determination The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at the mill shell's inside surface This is the rotational speed where balls will not fall away from the mill's shell : Mill Critical Speed Mill Speed Critical Speed Paul O Abbe Talk with the Experts at Paul O Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needscritical speed for a ballmill mayukhportfolioco

Ball mill Critical Speed YouTube

23122018 Cement Ball mill Critical speedcritical speed of ball mill theory Ball Mill Critical Speed Mineral Processing Metallurgy A Ball Mill Critical Speed actually ball rod AG or SAG is the speed at which the centrifugal forces equal gravitational forces at the mill shells inside surface and no critical speed of ballmill gruppozetasrlitprove of critical speed equtaion in ball mill clayart thread more ball mill questions Does one need to spend big bucks 800 to buy a ball mill from a potteryequipment formula N = 5419/square root of R where N is the critical per cent of the theoretical critical speedprove of critical speed of ball mill

Formula For Ball Mill Critical Speed

Prove Critical Speed Of A Ball Mill empart Prove Critical Speed Of A Ball Mill Milling Equipment: prove critical speed of a ball mill A class of machinery and equipment that can be used to meet the production requirements of coarse grinding, fine grinding and super fine grinding in the field of industrial grindingThe finished product can be controlled freely from 0 to 3000 A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sinteringIt works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow cylindrical shell rotating aboutBall mill Wikipedia